THR202C

Model TR201C Series Terminating Machine

Single-end tinning and single-end crimping machine THR202C

High Speed Processing

3,000 pieces per hour

(Single-end Tinning and Single-end Crimping)

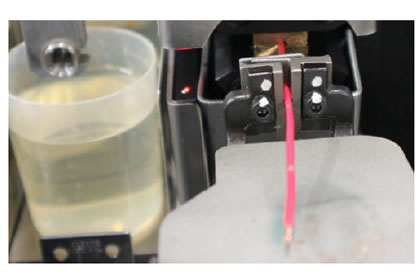

Improved tinning processing quality

Newly tinning unit has been utilized.

Approaching angle to tinning tank is approximately vertical.

Features

High Speed Processing

- Max. processing capability :

3,000 pcs/h

(R-side: Tinning and Twisting, F-side: Crimping) - Improvement ratio: 25%

(in-house comparison)

Newly developed Unit

- New Tinning and Twisting Unit

Improved tinning processing quality

- Tinning unit is equipped with the servo motor, for achieving stability insertion.

- Approaching angle to tinning tank is approximately vertical.

Improved Twisting processing quality

- Rotary twisting unit has been improved in twisting processing accuracy.

- Various processing conditions can be set.

Standard Specification

| Max. processing capacity | 3,000 pcs/h(Single-ends crimping and Single-end tinning) |

|---|---|

| Wire size | AWG 28-16 (0.08-1.25 mm2), Outer diameter 0.8-3.2 mm |

| Cutting length | 30 – 9,999 mm(1mm intervals) |

| Stripping length | F-side crimping: 0 – 15 mm |

| R-side tinning: 0 – 25 mm | |

| Twisting and tinning length | R-side: 2 – 20 mm |

| Press capacity | F-side: 19.6 kN (2.0 t) |

| Recommended tin | Wire solder 1.0 - 1.6mm dia. |

| Tinning temperature | 20 - 400℃ |

| Operation language | English, Japanese, Chinese |

| Primary power and Compressed air source | 3-phase AC200V±10% (50/60Hz), 0.5MPa 150L/min (ANR) |

| Dimensions | 920W×800L×1,430H mm (body only, excluding protrusions) |

| Weight | Main body: Approx. 430kg, Pre-feeder: Approx. 30kg |

- * Capability might change depending on the processing conditions and processing data. Processing may be difficult depending on wire type.

Contact Information

For product inquiries, please click the button below

Search for other products and services

ShinMaywa INSIGHT

March 09, 2022