TR201CS / TR201CSS

端子打機TR201Cシリーズ

端子打機TR201CS[片端ハンダ]

端子打機TR201CSS[両端ハンダ]

簡単段取り換えでヨリ・ハンダと端子圧着の両方が可能。

鉛フリーハンダに対応。

標準仕様

| 型式 | TR201CS[片端ハンダ]/TR201CSS[両端ハンダ] | |

|---|---|---|

| 電源 | 三相AC200V 20V 15A(50/60Hz) | |

| エア源※1 | 0.4~0.5MPa(4~5kgf/cm2)以上 60Nl/min | |

| モータ | 9軸ACサーボモータ(プレフィーダ含む) | |

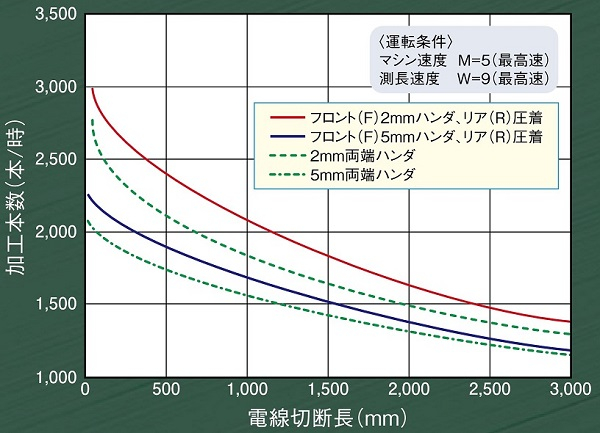

| 最大加工能力※2 (切断長:30mm、ストリップ:2mm) |

4500本/h (切断長:30mm、ストリップ:2mm、両端圧着時) |

|

| 両端圧着 | 4500本/h | |

| F:ハンダ、R:圧着 | 3900本/h | |

| F:ヨリ・ハンダ、R:圧着 | 3000本/h | |

| F:ヨリ・ハンダ、R:ヨリ・ハンダ | 2500本/h | |

| 最大切断長 | 9,999mm | |

| 最小切断長※3 | 30mm(両端圧着時)[設定入力は10mmまで可能] | |

| ストリップ長 | フルストリップ | 1~15mm(0.1mm 単位) |

| セミストリップ | 1~25mm(0.1mm 単位) [設定入力は0~30mmまで可能] |

|

| ヨリ長さ | F:2~15mm(実用)[設定入力は0~30mmまで可能] R:2~6mm(実用)[設定入力は0~15mmまで可能] |

|

| ハンダ長さ | F:2~15mm(実用)[設定入力は0~30mmまで可能] R:2~6mm(実用)[設定入力は0~15mmまで可能] |

|

| 加工電線※4※5 (ヨリ・ハンダ加工時) |

サイズ | AWG22~32[AWG18~36](撚り線) |

| 被覆外形 | [⌀ 2.5~]⌀ 1.6~0.5mm | |

| 圧着能力 | 14.7kN(1.5t) | |

| 圧着端子※6※7 | オープンバレル連続端子(サイドフィード、エンドフィード) | |

| 糸ハンダリールサイズ | 内径⌀ 12mm以上 外径⌀ 85mm以下 幅75mm以下 | |

| 推奨使用環境温度 | 15~25℃ | |

| 質量 | 本体:[片端ハンダ]430kg [両端ハンダ]440kg プレフィーダ:30kg |

|

- ※1水分、油分、ほこりなどを含む圧縮エアは機械故障の原因となります。

- ※2加工能力は、加工品の仕様、条件、ハンダの付き具合などにより低下する場合があります。

- ※3最小切断長は使用されるアプリケータ、電線の種類、加工条件などにより変化します。オプションの特殊クランプを使用することにより、さらに短い加工も可能な場合があります。ご相談ください。

- ※4AWG22より太い、またはAWG32より細い電線については、ウレタンローラ、特殊クランプなどを使用することにより加工可能な場合があります。ご相談ください。

- ※5最大外径⌀ 2.5mmまでの電線がセット可能ですが、斜めにハンダ付けする構造上、被覆外径⌀ 1.6mm以上の電線では被覆がハンダに触れる場合があります。

- ※6ハンダユニットを取りはずし、アプリケータを搭載する場合は、オプションの「着脱プレート」が必要です。

- ※7エンドフィード端子の場合は、オプションの「エンドフィード用リールハンガ」が必要です。

加工能力

特長

簡単段取り換え

ハンダ槽・フラックス槽が静止槽なので、ハンダ・フラックスの消費量・飛散量が軽減できます。

(0.1mm単位でフラックス付け位置が設定可能。)

極細線対応ヨリ機構

極細・極短線でも高精度なヨリ加工が可能。ヤスリの配置を縦置きにし、コンパクトにしました。

液面検知

センサでハンダの液面を検知し、自動でハンダを供給するため、常に液面を一定に保ちます。

温度調節

読みやすいデジタル表示なので、簡単に温度設定ができます。400℃までの高温設定が可能。鉛フリーハンダに対応します。

お問い合わせ先

製品に関するお問い合わせはこちらからお願いいたします。

ほかの製品・サービスを探す