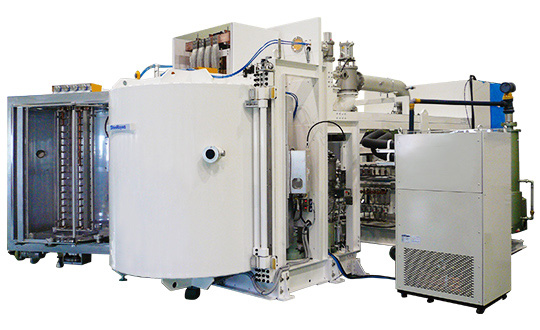

Batch type vapor deposition + plasma polymerization system

Features

- Two vertical doors provide high productivity

- Direct evaporation on plastic substrate and protective film coating by parallel electrode for plasma generation produce high quality deposition

- Advanced current control device minimizes aluminum splash during evaporation

- Electric driving is available for door open and close to lessen the operator' s workload(option)

Specifications

| Model | VCD1000AD | VCD1300AD | VCD1450AD | VCD1800AD |

|---|---|---|---|---|

| Substrate size (Including jigs, etc.) |

φ350×1,200mm 4 axes φ320×1,200mm 5 axes |

φ400×1,200mm 6 axes φ450×1,200mm 5 axes |

φ450×1,500mm 6 axes φ500×1,500mm 5 axes φ550×1,500mm 4 axes |

φ450×1,500mm 8 axes φ550×1,500mm 6 axes |

| Model | VRD650AD | VRD750AD | ||

|---|---|---|---|---|

| Substrate size (Including jigs, etc.) |

φ540×1,500mm 2 axes | φ600×1,500mm 1 axis |

Main use

- Formation of reflective and protective films for automobile lamp reflectors and other automobile interior and exterior parts

- Formation of reflective films for cosmetic containers, mirror parts, etc.

Contact Information

For product inquiries, please click the button below

Search for other products and services

ShinMaywa INSIGHT

March 09, 2022