Ion Etching System

Technical Information

What is Ion Etching System?

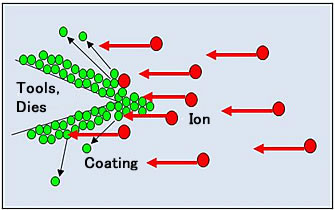

Ion Etching is one of the physical cutting techniques by bombarding an object with ionized atom.

Using our own techniques, ShinMaywa has developed a de-coating system for cutting tools, dies and other parts.

De-coating means removing coatings from a substrate and makes it possible for the substrate to reuse.

There is a de-coating method using chemical but it may cause damages to a substrate and uses different chemical liquids depending on coating types.

When using hard metal alloy as a substrate, its component, cobalt is melted by chemical and the surface gets damaged, therefore it is considered to be difficult to reuse.

ShinMaywa's Ion Etching system uses a useful de-coating method replacing with using chemical methods.

Our system irradiates ions under dry environment, there is no cobalt (Co) elution contained in carbide substrate and the damage to the surface of the substrate can be minimized. In addition, it is gentle to human bodies and environment.

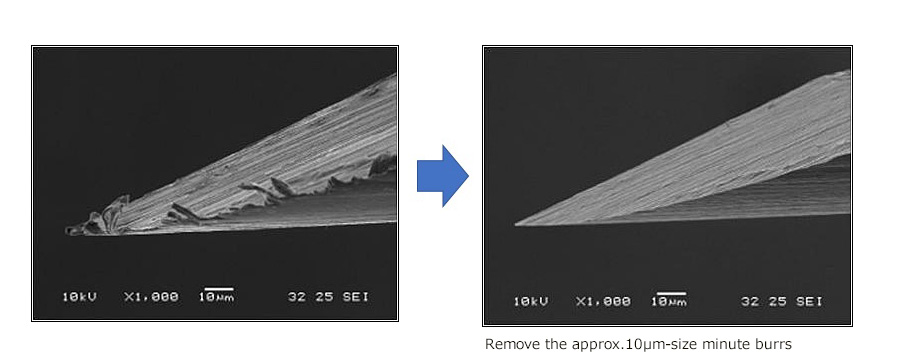

Not only for "de-coating" but it can be also used for "de-burring" and "sharpening of edges".

Advantage

By allowing the base material to be reused by removing the film, costs such as base material costs and processing costs can be reduced.

For customers who own film coating system, it can be used as a recovery in case of a coating error.

Since no chemicals are used, there is no need for waste liquid treatment and environmentally friendly.

ShinMaywa's Ion Etching System

We have a lineup of compact and standard types for system sales. Compact type is downsized and effective for small scale of production and can be used for various types of items.

We offer the best system considering customers' specific needs.

System Specifications and De-coating Object

| System specifications | ||

|---|---|---|

| Series | IE series | cIE series |

| Size | W 2,300mm | W 900mm |

| D 1,400mm | D 1,200mm | |

| H 2,350mm | H 1,700mm | |

| Weight | Approx. 1,600kg | Approx. 700kg |

| Gas | Ar, O2 | Ar, O2 |

| Ion guns | 4, 6, 8 sources | 3, 5 sources |

| Max elec. consumption | 19-31kVA | 9-12kVA |

| De-coating object (coating) | |

|---|---|

| Carbon | Diamond coating, DLC |

| Nitriding | TiN, TiAlN, AlN, AlCrN, TiCrN, CrN etc. |

| Metal | Si, Cr etc. |

Application examples

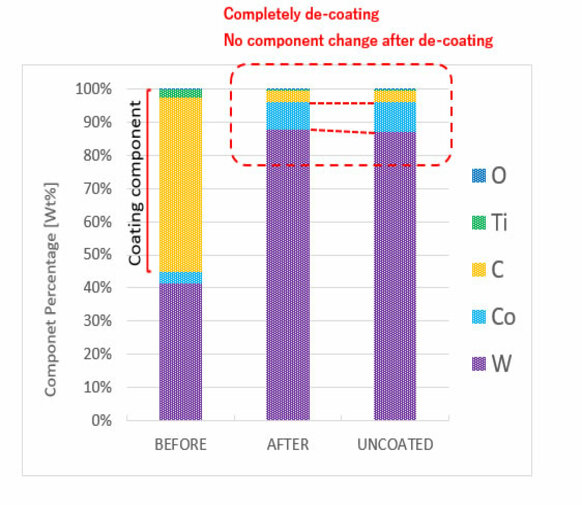

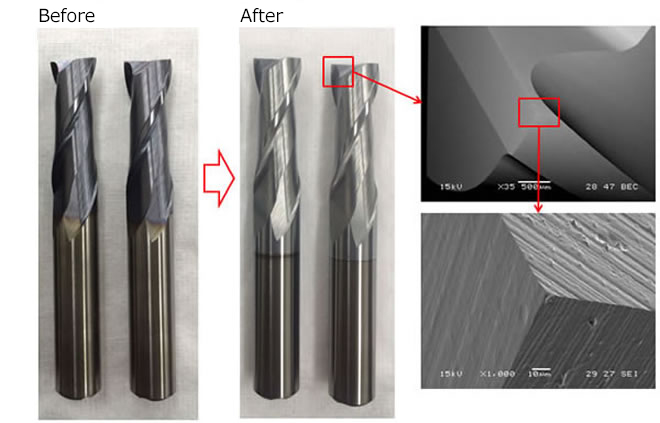

Coating tools on carbide substrates

- Coatings can be removed without damaging carbide materials.

- The shape and sharp cutting edge can be maintained even after membrane removal.

- It can also be applied to materials other than carbide base materials.

De-coating Example of Carbide Endmill

AlCrN series

Substrate:Carbide

Coating type:AlCrN(2-3μm)

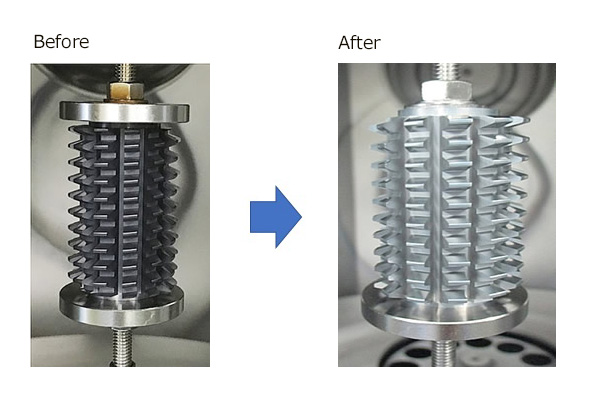

De-coating Example of Carbide Hob Cutter

Movie

【コーティングの除膜、先鋭化!】新明和工業のイオンエッチング装置

De-coating Example of Carbide Punch

Movie

【新明和のイオンエッチング装置】★基材へのダメージを最小限に抑え、超硬工具等の再利用を可能にします!

Lens mold

Deburring effect of injection needle

Contact Information

For product inquiries, please click the button below

Search for other products and services