Diamond Coating System

System sales / Contract development

Technical Information

What is Diamond Coating System?

ダイヤモンドは、現存する物質で最も硬い材料として、機械的、電気的、化学的、熱伝導特性において非常に優れた物質です。この優れた特性のコーティングが活用できれば、様々な分野で応用が可能であり、研究開発が進められております。

ダイヤモンドを合成する方法として、高温高圧法、熱フィラメントCVD法、マイクロ波プラズマCVD法などがあり、切削工具、金型、人工宝飾、電解電極、半導体デバイス、放熱基板、量子センサなど、今後も様々な応用が期待されています。

ShinMaywa’s Diamond Coating System

- 熱フィラメントCVD法を採用し、φ300ウエハなど大面積にダイヤモンドを合成することが可能です。

超硬切削工具へのコーティングなど量産品への適用も可能です。 - 独自技術により密着性を最適化し、超硬素材だけでなくセラミックス、耐熱金属など様々な材質にもコーティング可能です。

- 導電性ダイヤモンド被膜形成にも対応しております。

- 装置販売および受託開発もお請けいたします。

- 当社イオンエッチング技術を生かし、除膜~再成膜といったリサイクル提案も可能です。

Application

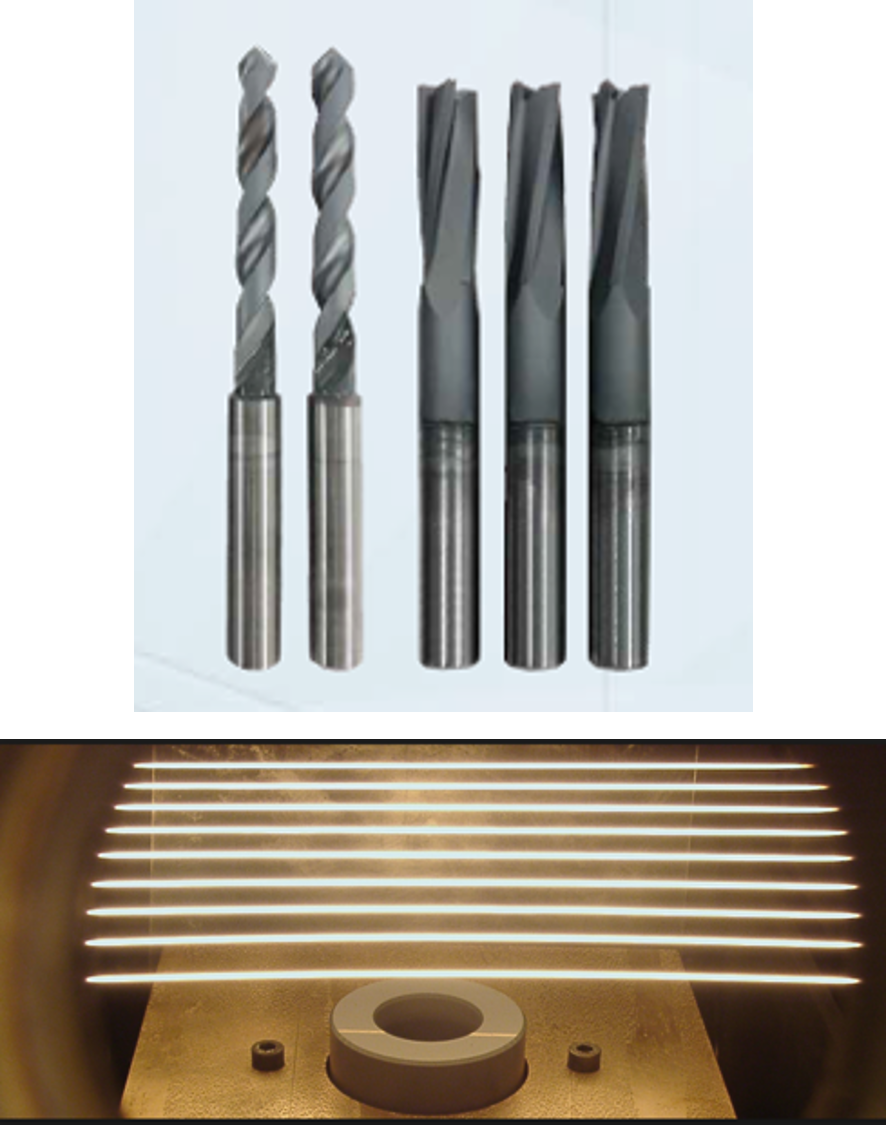

- 切削工具 :超硬加工、CFRP加工、グラファイト加工、アルミ合金加工

- 金型 :DLC以上の長寿命化

- シール部品:メカニカルシール摺動面(SiC、超硬)の耐久性向上

- 電解電極 :CO2還元、オゾン水生成など

- 放熱基板(ヒートスプレッダ)

- * Please contact us about developing new applications.

System specifications

| SDC300 | SDC100 New! | |

|---|---|---|

| System/Method | Hot Filament CVD | |

| Device dimensions (mm) |

L2,480×W1,320×H2,240 | L950×W2,300×H1,830 |

| Chamber Dimensions (mm) |

L620×W600×H500 | Lφ440×H470 |

| Can be installed Size (mm) |

工具:φ0.5 - φ20 L200 平板:φ300 t30 |

Rod shape: φ0.5 - φ20 L100 Flat plate: L100 x W150 x H30 |

| Substrate material | 超硬(WC-Co)、シリコン(Si)、セラミックス(SiC)、耐熱金属(Nb)など | |

| Coating length (mm) | 50 | 10 |

| Power supply | 3 phase 200V 50kVA A type ground connection | 3 phase 200V 20kVA class A grounding |

| Coolant | 25L/min | |

| Gas | CH4, H2, N2 and other ports can be added | |

| Weight | 2,000kg | 1,200kg |

The small dedicated machine SDC100 can also be modified to fit special shapes such as molds.

- * Due to diamond coating temperature will be around from 800degC to 900degC, substrate material shall be

limited heat-resistant material.

For coating on cobalt content carbide, de-cobalt pretreatment is required.

Also our pretreatment system can be offered as turnkey.

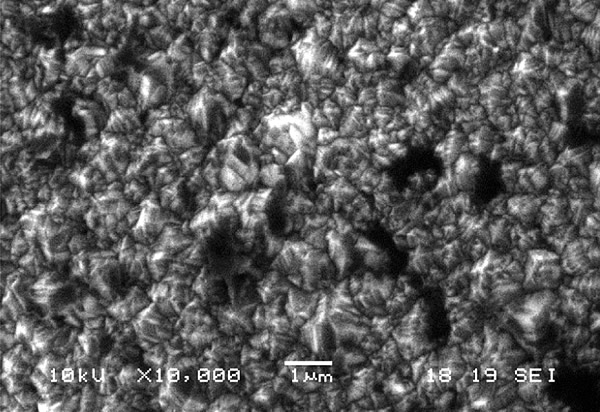

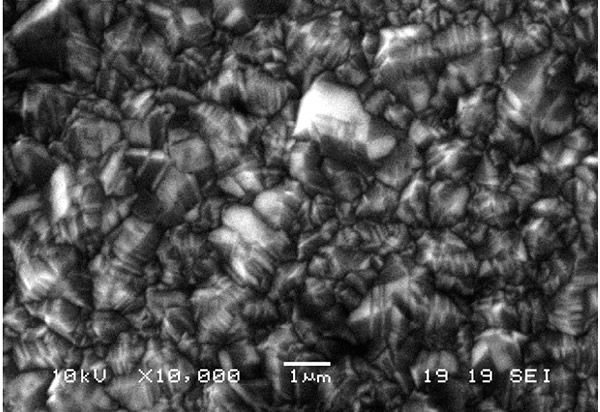

Optimized diamond grain size can be offered for each applications.

We also offer polishing techniques after diamond deposition.

We can also propose microwave plasma CVD equipment.

- DIAVAC Limited (our group)

Application examples

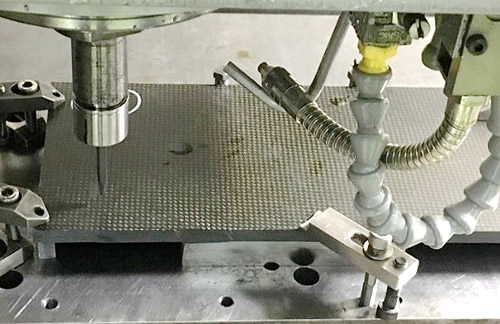

CFRP drilling test of same tool shape and different coating #1

Drill size:⌀7.95 L90

CFRP thickness:8.5mm

Dry processing

CFRP thickness:8.5mm

Dry processing

Movie

【Shinmaywa's Diamond coating system】 We use the "Hot filament CVD method."

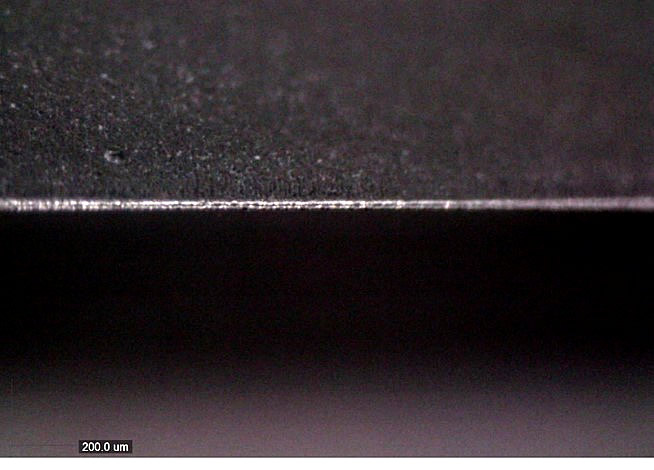

Improvement of wear condition of tool edge after 100 holes

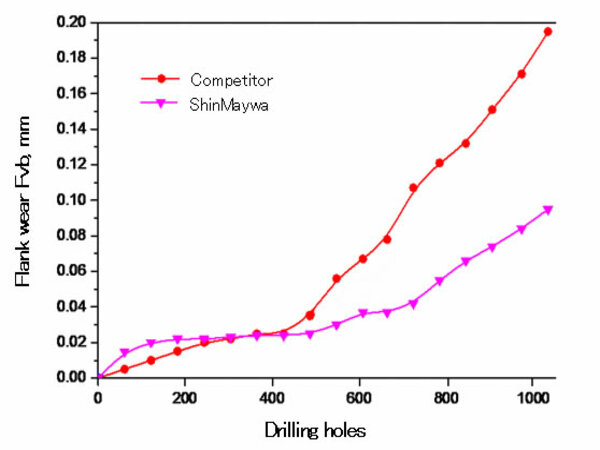

CFRP drilling test of same tool shape and different coating #2

Dirll size:⌀3.28

CFRP thickness:8mm

Dry cutting

CFRP thickness:8mm

Dry cutting

Reduce wear and extend tool life!

Click here for microwave plasma CVD equipment

- DIAVAC Limited (our group)

- https://www.diavac.co.jp/item1/Microwave plasma CVD equipment/

Contact Information

For product inquiries, please click the button below

Search for other products and services

ShinMaywa INSIGHT

March 09, 2022