プラズマイオン処理装置

装置販売

技術情報

プラズマイオン処理装置とは

プラズマイオン処理はプラズマにより生成されたイオンを用いて表面改質を行う技術です。

応用事例としては、窒化処理や金属加工物の形状改善に適用できます。

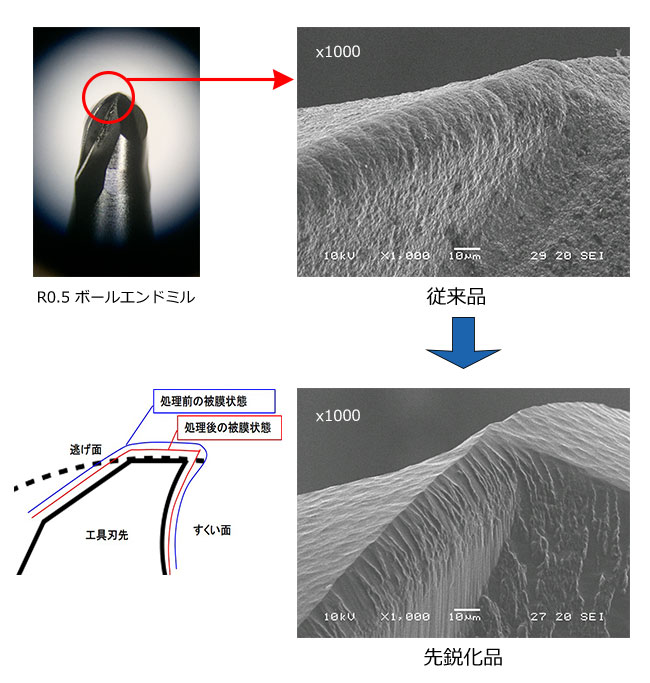

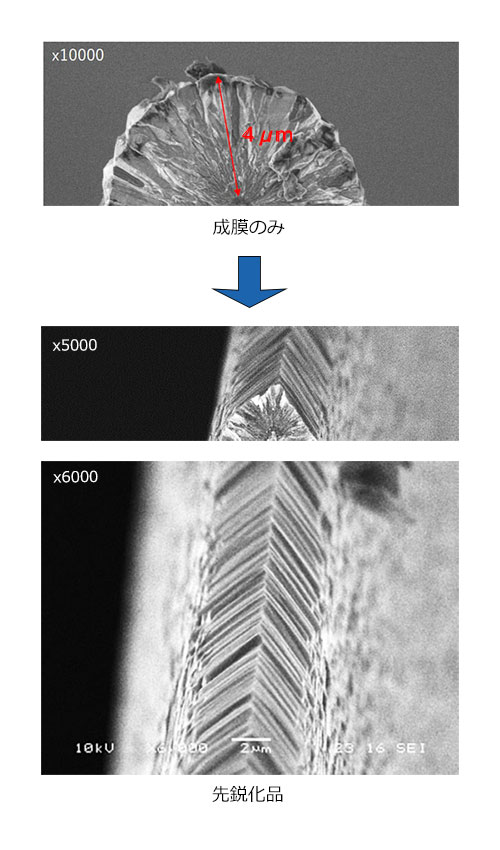

プラズマ処理による工具先鋭化

ダイヤモンド被覆工具

独自のプラズマ処理によりダイヤモンドコーティング刃先の先鋭化

ダイヤモンドコーティングを施すと耐摩耗性、寿命は良好!

しかし、刃先が丸くなるので切れ味が。。。

基材にダメージを与えることなく被膜自身を先鋭化

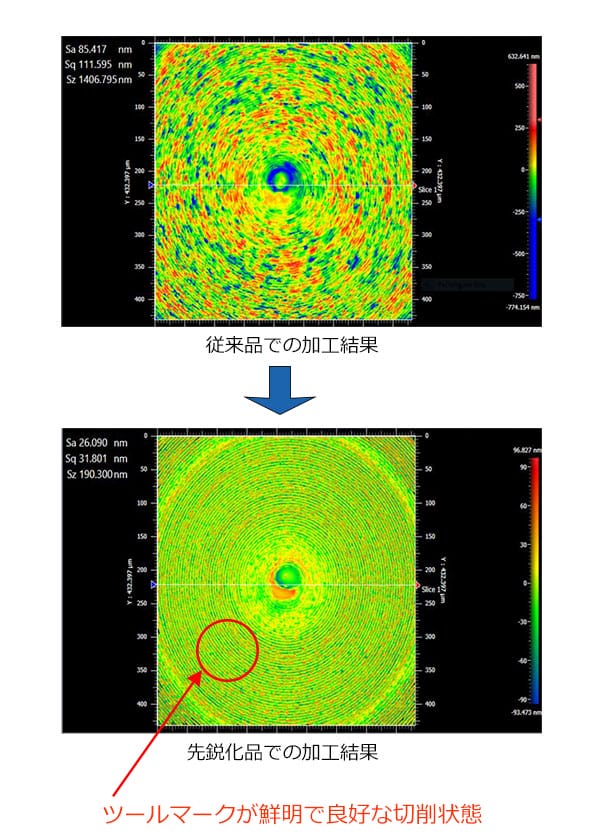

先鋭化工具での加工テスト

(右)先鋭化品での加工面

| 工具 | R0.5 ダイヤモンドコーティングボールエンドミル |

|---|---|

| ワーク | 超微粒超硬(レンズ型加工) |

| 評価 | 加工面の表面状態比較

|

ダイヤモンド刃物

プラズマ窒化

プラズマ窒化の原理

ホローカソード型プラズマソースで窒素プラズマを生成し、真空チャンバ―内へ送り込みます。

窒素プラズマのイオンは、ワークに印加されたバイアスにより引き込まれ、衝突および侵入します。ワーク表層は窒素系の金属間化合物が生成されます。

プラズマ窒化の特長

- 環境負荷の少ないアルゴンガス、窒素ガスを使用。作業環境に優しい(アンモニアガス不要)

- プラズマパワーのみで窒化温度まで昇温可能。構造がシンプル。

- ステンレス鋼への窒化処理可能

メリット

- 硬度の向上

- 耐摩耗性の向上

- 耐食性の向上

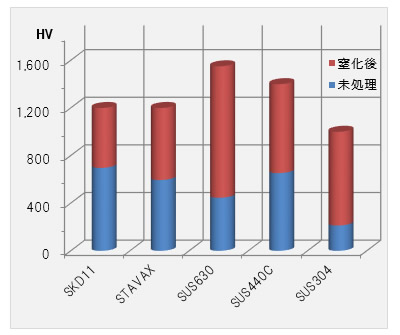

各種材質の表面硬度

| 処理前(HV) | 処理後(HV) | |

|---|---|---|

| SKD11 | 697 | 1200 |

| STAVAX | 595 | 1200 |

| SUS630 | 446 | 1550 |

| SUS440C | 653 | 1400 |

| SUS304 | 213 | 1000 |

応用例

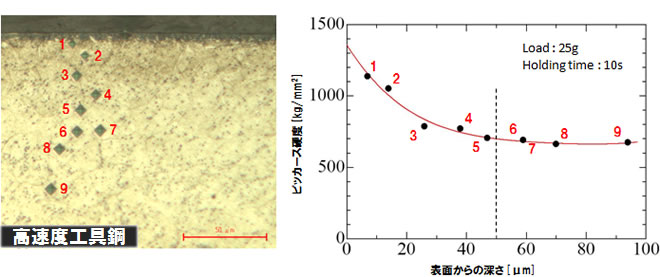

高速度工具鋼への適用

高速度工具鋼への窒化処理後の断面図(左)と表面からの硬度変化(右)を示します。

表面から深さ方向へビッカース硬度計を用いて、数点を測定します。

対象材料や処理条件によって、表面硬度の程度は変化します。

装置仕様

| 仕様 | |

|---|---|

| サイズ | W 2,200mm |

| D 2,100mm | |

| H 2,650mm | |

| 質量 | 約 2,600kg |

| 使用ガス | Ar, N2 |

| 処理温度 | <500℃ |

| プラズマ源 | 1基 |

お問い合わせ先

製品に関するお問い合わせはこちらからお願いいたします。

ほかの製品・サービスを探す