Started sales of large ion beam source "Linear Ion Source"

September 3, 2024

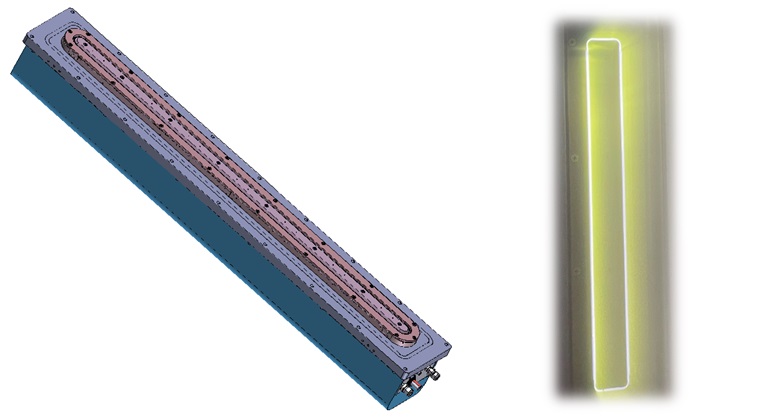

ShinMaywa Industries, Ltd. (Head Office: Takarazuka-shi, Hyogo; President and CEO: Tatsuyuki Isogawa) has developed and started selling an electromagnetic coil type "large ion beam source, the Linear Ion Source," which is used for surface treatment in the vacuum deposition area in the manufacturing process of high-performance films and for removing coatings from large tools. The newly developed "Linear Ion Source" is capable of irradiating large objects, and by using an electromagnet to form the magnetic field, it has also achieved improved workability and maintainability.

This linear ion source will be exhibited at the 32nd Japan International Machine Tool Fair (JIMTOF2024), which will be held at Tokyo Big Sight from November 5th.

Background of development

Linear ion sources generally use powerful permanent magnets to create the magnetic field that generates a high-energy ion beam. However, when metal dust generated during the removal of metal coatings is attracted to and accumulates on the permanent magnets, the ion beam becomes unstable. This requires periodic maintenance to remove the metal dust, but the problem is that the components that make up the ion source cannot be easily removed due to the influence of the permanent magnets.

Currently, there are only a few companies in Japan that manufacture and sell linear ion sources, and most of them are made in Europe or the US. As the need for large-sized ion beam sources increases due to changes in the manufacturing process of high-performance films, and the range of coatings required for recycling by removing the coatings from cemented carbide tools expands, customers have been requesting linear ion sources made by domestic manufacturers.

Advantages of our electromagnetic coil type "linear ion source"

In light of this, we have developed a "linear ion source" that uses an electromagnet that creates a magnetic field by passing an electric current through a coil, applying the coil system used in the "round ion source" installed in our "ion etching equipment." In order to irradiate large objects, we have derived the optimal arrangement of multiple electromagnets and selected a coil with appropriate specifications to achieve a long length. As a result, magnetic force is not generated except when the ion beam is in operation, which suppresses metal dust adhesion, reduces the frequency of maintenance, and enables long-term continuous operation, improving work efficiency. In addition, parts can be easily attached and detached during maintenance, improving maintainability.

In the future, we plan to focus on selling components that combine linear ion sources and power supplies to other equipment manufacturers, and also to propose our large ion etching equipment equipped with linear ion sources.

In addition to ion etching equipment, we also offer a lineup of diamond coating equipment that enhances wear resistance, and in cooperation with group companies DIAVAC Limited and KOREA VACUUM LIMITED, which are involved in the vacuum business, we are able to consistently provide optimal thin film and surface treatment technology that meets customer needs. We will continue to develop the vacuum technology we have cultivated so far and strive to create technology that meets the needs of society.

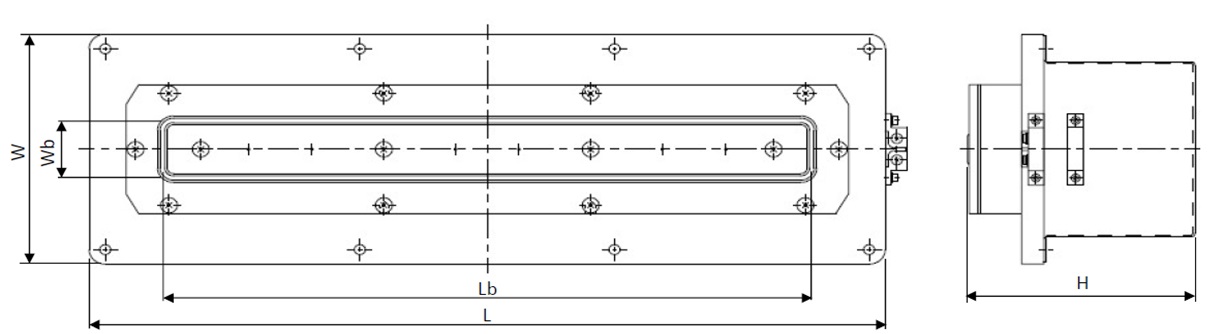

1. Features

- Beam irradiation is possible over a large area of 400 to 1,000 mm in length

- A magnetic field is generated by electromagnets, without the use of permanent magnets.

This reduces the adhesion of metal dust, improving maintainability.

2. Main specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3. Purpose

- Etching and cleaning in high-performance film manufacturing

- Removing coating from large workpieces, etc.

4. Main sales destinations

- Manufacturer of deposition equipment for films and flat substrates

- Tool manufacturers, coating manufacturers

5. Sales start date

August 2024

6. Sales Target

30 units/year and up

7. Glossary

- Ion source: An instrument that produces atomic and molecular ions.

- Linear ion source: A long, rectangular ion source. Compared to a round ion source, it can irradiate an ion beam over a wider area.

- Ion etching equipment: A device that bombards ions into an object to physically remove it. This technology is used to remove coatings from substrates such as cutting tools, molds, and various parts.

Contact Information

For news organizations

Public Relations Department, Corporate Planning Division, ShinMaywa Industries, Ltd.

1-1 Shinmeiwa-cho, Takarazuka, Hyogo, 665-8550, Japan

About products

Mechatronics Department, Industrial Machinery Systems Division,

ShinMaywa Industries, Ltd.

1-1 Shinmeiwa-cho, Takarazuka, Hyogo, 665-8550, Japan

The information published in this content is current as of the date of publication.

Please note that this information may differ from the latest information due to changes in our group's business strategies and organization.