Products

Automatic Wire Terminating Machines

Various kinds of electrical wire are used in wiring of many equipments such as automobiles, electrical appliances, cellular telephones and laptop computers. The Automatic Wire Terminating Machine of ShinMaywa automatically cuts and crimps terminals at a high speed and accuracy is highly appreciated for its superior quality after processing by automobile harness makers. And we have a sufficient support system abroad.

Digital Showroom

Product Lineup

Available process TR/TRD series

| Series | TR201C TR202C THR202C |

TRD301C TRD302 |

TR500 (End of sales) TRD510 |

TRD602 THR602 |

TRD701 TRD711 |

TRD801 |

|---|---|---|---|---|---|---|

| Wire size

|

0.013 – 1.25 mm2 (AWG36 - 16) |

0.13 – 5.0 mm2 (AWG26 - 10) |

0.08 – 2.0 mm2 (AWG28 - 14) |

0.08 – 1.25 mm2 |

0.08 – 6.0 mm2 | 0.03 ~ 1.25 mm2 ( AWG32 ~ 16 ) |

| Press capacity | 14.7~19.6 kN (1.5 ~ 2 t) |

24.5~39.2 kN (2.5 ~ 4 t) |

19.6 kN (2 t) |

24.5kN (2.5 t) |

24.5kN (2.5 t) |

24.5kN (2.5 t) |

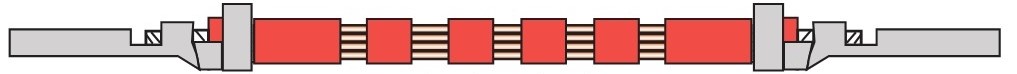

Both-ends crimping |

○ | ○ | ○ | ○ | ○ | ○ |

Both-ends crimping and intermediate stripping |

ー | ○ | ー | ー | ー | ー |

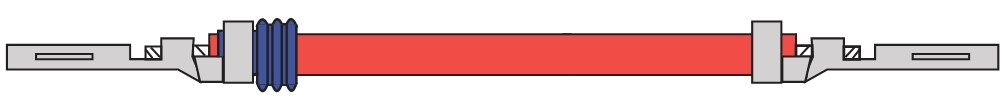

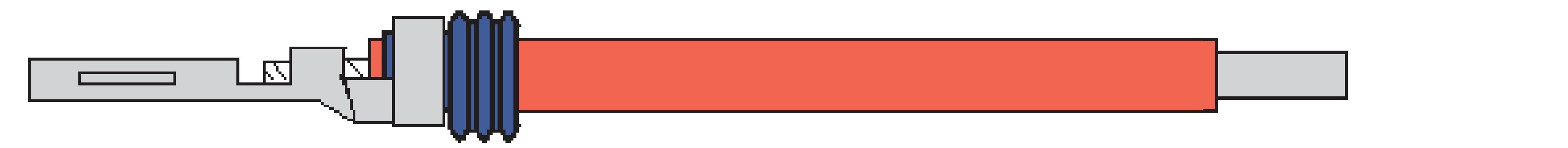

Both-ends crimping and single-end seal insertion |

ー | ○ | ○ | ○ | ○ | ○ |

Both-ends crimping and seal insertion |

ー | ○ | ○ | ー | ○ | ー |

Single-end crimp and single-end tinning |

○ | ー | ー | ○ | ー | ー |

Single-end crimping, seal insertion and single-end tinning |

ー | ー | ー | ○ | ー | ー |

Both-ends tinning |

○ | ー | ー | ー | ー | ー |

- *Applicable wire size changes with parts or optional parts to be mounted.

- *The mm2/AWG conversion of the wire size is for reference only.

- *Some wires are difficult to process.

- *Please contact us when special wires need to be processed.

Contact Information

For product inquiries, please click the button below