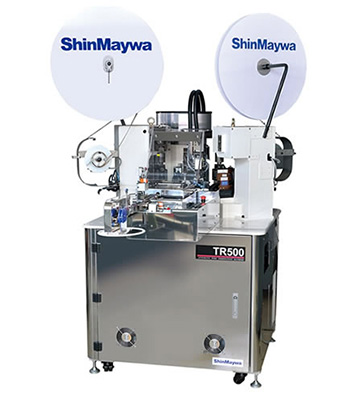

Model TR500 Series Terminating Machine

With industry-leading processing capability and less space requirement,

the ShinMaywa TR500 series machines improve productivity and reduce processing cost.

The TR500 series has achieved the top-class maximum processing capacity of 6,000 pieces/hour as the single-wire crimping system that can use any genuine applicator of respective companies (compared to our company's products).

This machine is provided with a newly developed system consisting of "S axis and Y axis" mechanism in the feed unit. The latest controllers and servo motors have achieved high-speed and high accuracy crimping, which has significantly increased the processing capacity.

The newly belt feed designed mechanism unit allows delicate wires to be fed at high-speed. In addition, the feedback correction control increased the cut length accuracy and stability using an encoder.

By reducing path line wire inlets to 50% from previous equipment, the setup time has reduced significantly. This machine achieves high-speed performance, high durability, easy maintenance and very friendly software.

The TR500 is equipped with various options using high technical capabilities.

ShinMaywa Industries proposes best suited products for the ever-developing market.

Available process for each model

| Model | TR500 | TRD510 | TRD510WPSA | TRD510WPA |

|---|---|---|---|---|

| Wire size

|

0.08 – 1.25 mm2 |

0.13 – 2.0 mm2 (AWG26 - 14) |

||

| Press capacity | 19.6 kN (2 t) |

|||

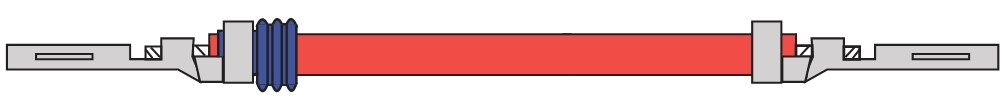

Both-ends crimping |

○ | ○ | ○ | ○ |

Both-ends crimping and single-end seal insertion |

ー | ー | ○ | ○ |

Both-ends crimping and seal insertion |

ー | ー | ー | ○ |

- *Applicable wire size changes with parts or optional parts to be mounted.

- *The mm2/AWG conversion of the wire size is for reference only.

- *Some wires are difficult to process.

- *Please contact us when special wires need to be processed.

Standard Specification

| Model | TR500 | TRD510 | TRD510WPA | TRD510WPSA | ||

|---|---|---|---|---|---|---|

| Max. processing capacity*1 | Both-ends crimping | 60 mm | 6,000 pcs/h | ー | ||

| 100 mm | ー | 5,000 pcs/h | ||||

| 500 mm | 4,800 pcs/h | 4,200 pcs/h | ||||

| 1,000 mm | 4,200 pcs/h | 3,750 pcs/h | ||||

| Both-ends crimping with seal insertion | 100 mm | ー | ー | 3,000 pcs/h | ||

| 500 mm | ー | ー | 2,700 pcs/h | |||

| 1,000 mm | ー | ー | 2,500 pcs/h | |||

| Cutting length | 最小(入力値)ー最大 | 30 ー 20,000 mm※2 | 50 ー 20,000 mm | |||

| Stripping length | 最小ー最大 | 1 ー10mm | 1 ー 16 mm | |||

| Crimping | Press capacity | 19.6 kN (2 t) | 19.6 kN (2 t) Digital crimper | |||

| Crimping terminals | Continuous open barrel, Side/End feeding Continuous closed barrel*3 |

|||||

| Seal insertion | Seals | ー | ー | Max. outer diameter:8 mm, Max. length 12 mm, Round shape rubber seals*4 | ||

| Seal unit | ー | ー | 3-module both-ends | 3-module single-end | ||

| Equipment | Safety cover | Openable cover | Partial openable safety cover | |||

| Wire chopper | Option | Standard | ||||

| Terminal crimping monitor | Option | Standard | ||||

| Sensor | Crimping | Standard (photoelectric) | Standard (terminal crimping monitor) | |||

| Stripping | Standard | |||||

| Terminal presence | Standard | |||||

| Wire presence/Joint | Standard | |||||

| Wire tension overload | Standard | |||||

| Wire slipping | Standard | |||||

| Input | Input | Touch panel | Mouse & keyboard | |||

| Language | English/Chinese/Japanese | English/Spanish/Chinese/Thai/Japanese | ||||

| Operator permission setting | 2 levels | 3 levels | ||||

| Wire feeding | Practical typical speed of belt-feeding mechanism: 6 m/s, Max. speed: 10 m/s | |||||

| Driving motor | AC servo motor for all axes | |||||

| Power supply | 3-phase 200 VAC ±10% (50/60 Hz) | |||||

| Max. power consumption | Approx. 0.4 kWh | Approx. 0.42 kWh | ||||

| Compressed air source | 0.5 MPa 150 ℓ/min (ANR) |

0.5 MPa 170ℓ/min (ANR) |

0.5 MPa 160ℓ/min (ANR) |

|||

| 本体質量 | Approx. 600 kg | Approx. 690 kg | Approx. 710 kg | Approx. 700 kg | ||

- *1Capacity might change depending on the processing conditions and parameter.

- *2A clamp for short wire may be required for both-ends crimping for 50mm (or less) wire.

- *3Only TRD510 series are supported. Please contact us in advance when considering processing continuous closed barrel terminals.

- *4For wire-seal combinations, please contact us.

Outside Dimensions

Contact Information

Click here for product inquiries.