Semi-automatic machines & Peripheral devices

Desktop Digital Crimper (TRP256DM Series)

The crimping part is separate from the automatic terminating machine "TRD301" for the auto industry.

With numerical control, fine adjustments can be made by 1/100 mm in the caulking height and by 1/100 second in the processing speed.

| Model | TRP256DM | TRP256DM-4T |

|---|---|---|

| Press capacity | 24.5kN (2.5t) | 39.2kN (4.0t) |

| Crimping stroke | 30/40mm (changeable) | |

| Terminal feeding | Side, end feed | |

| Crimping height setting | 0.01mm unit | |

| Data memory | 100 data | |

| Operation language | Japanese, Chinese, English, Spanish | |

| Option | Crimp force monitor, Signal tower, etc. | |

| Power supply | 3-phase AC200V (50/60Hz) ± 10% | |

| Dimensions | 437W×497.5L×591H mm | |

| Weight | 140 kg | |

Semi Automatic Strip Crimper With Seal insertion (WSC Series)

This machine can automate the seal insertion, strip and crimping processes for multi-core cables and single wires.

- 1 Automatic 3 seals changeover technology from our TRD series is integrated for stable seal insertion and simple seal change or easy transfer to another machine.

- 2Minimum Sheath removal length with multi-core cable is 50mm for WSC-12 and 35mm for WSC-11W.

- 3 Improved crimping accuracy for bended wires by cutting the tip of the wire (tip cutting is standard function).

| Model | WSC-12 | WSC-11W |

| Processing description | Single wire processing | 2 wire processing (single wire processing is not available) |

| Seal insertion / Strip / Crimping | Seal insertion / Strip / Crimping | |

| Wire size | 0.13 - 1.25sq Wire length over 80mm Sheath removal length over 50mm |

Select one from 0.3 - 0.85sq Sheath removal length over 50mm |

| Max. processing capacity | 1.7sec/pc. with seal insertion | 3.6sec/pc. with seal insertion |

| 1.3 sec/pc. without seal insertion | 1.8 sec/pc. without seal insertion | |

| Press capacity | 24.5kN(2.5t) | |

| Terminal feeding | Side, end feed (end reel hangers are optional) | |

| Crimping height setting | 0.01mm unit | |

| Stripping length | 2.00 - 7.00mm (0.01mm unit) | |

| Tip cut | 1.00mm - 2.00mm (0.01mm unit) | |

| Data memory | 999 data | |

| Operation language | Japanese, Chinese, English, Spanish | Japanese, Chinese, English, Spanish, Indonesian |

| Option | Crimp force monitor, Interlayer paper winder, Attachment, Foot switch, etc. | |

| Power supply | 3-phase AC200V (50/60Hz) ± 10% | |

| Compressed air source | 0.5 MPa or over | |

| Dimensions | 650W×700L×1750H mm | 650W×800L×1750H mm |

| Weight | Approx. 400kg | |

Accumulator (TRA Series)

High speed and stable wire feeding bring out the maximum performance of the automatic wire processor.

By feeding wires stably, "wire tangling", "jamming at the length measuring section" and other "tendency of wire" can be improved.

| Model | TRA2500WSB | TRA2500WS | TRA2500B | TRA4000 |

| Wire supply | Bobbin, Wire spool | Wire spool | Bobbin | Wire spool |

| Wire size*1 | 0.08 - 0.5sq | 0.13 - 2sq | ||

| Applicable bobbin | P type: P2 - P30 *2 | ー | ||

| Max. supply capability | 2,500 mm/s | 4,000 mm/s | ||

| Power supply | 1-phase(50/60Hz) AC200-240V or AC100-115V | |||

| Compressed air source | 0.5±0.1Mpa | |||

| Dimensions | 1200mm(W) × 520mm(L) × 890mm(H)*3 | 1200mm(W) × 500mm(L) × 950mm(H) | ||

| Weight | 75kg *3 | 70kg | ||

| Installation possible models | TR201, TRD301, TR500, TRD510, TRD602, TRD701, TRD801 series | TRD510, TRD701 series | ||

- *1 The applicable wire range is for reference. Feeding may be difficult depending on the wire type.

- *2 For details of the bobbin requirements, please contact us.

- *3 Dimensions and Weight in case of TRA2500WSB

Rubber Seal Feeder (RF100)

Rubber seals can be stably fed to the seal insertion automatic wire terminating machine.

- 1 High-speed feed is achieved by specializing in rubber seal feed, standard 55 pieces/min, maximum 67 pieces/min

- 2 Unique feed structure enables stable feed of rubber seals

- 3 Rubber seals can be changed by replacing rubber seal-specific parts.

If the outer diameter of the rubber seal is different: Replace 7 parts.

If the rubber seals have the same outer diameter and different heights: Replace 2 parts.

| Model | RF100 |

| Applicable rubber seal *1 | Circular rubber seal Rubber seal outer diameter 10mm or less, rubber seal length 12mm or less The length of the rubber seal is 1 mm or more than the outer diameter of the rubber seal. |

| Rubber seal feeding capacity *2 | Standard 55 pieces/min Max. 67 pieces/min |

| Rubber seal feeding direction | Standard pressure feeding |

| Power supply | Single phase AC100~240V (50/60Hz) |

| Air *3 | 0.5~0.55MPa 120L/min(ANR) |

| Dimensions | Width 344 x Depth 580 x Height 870mm (excluding protrusions) |

| Weight | Approximately 33kg (including control box) |

| Operating conditions | Room temperature: 10-40℃, humidity: 85% or less (no condensation) |

| Option | Display (controller), seal cassette connection parts Spare bottle, positioning adjustment jig |

- *1 Applicable rubber seals may not be compatible depending on the type of rubber seal.

If we do not have a track record, we will evaluate each rubber seal to see if it can be used.

Oval and hard shell rubber seals are not applicable. - *2 The maximum feed capacity of the rubber seal may not be satisfied depending on the type and shape of the rubber seal and the capacity of the machine.

- *3 Air volume varies depending on the type of rubber seal. This device does not have a pressure sensor.

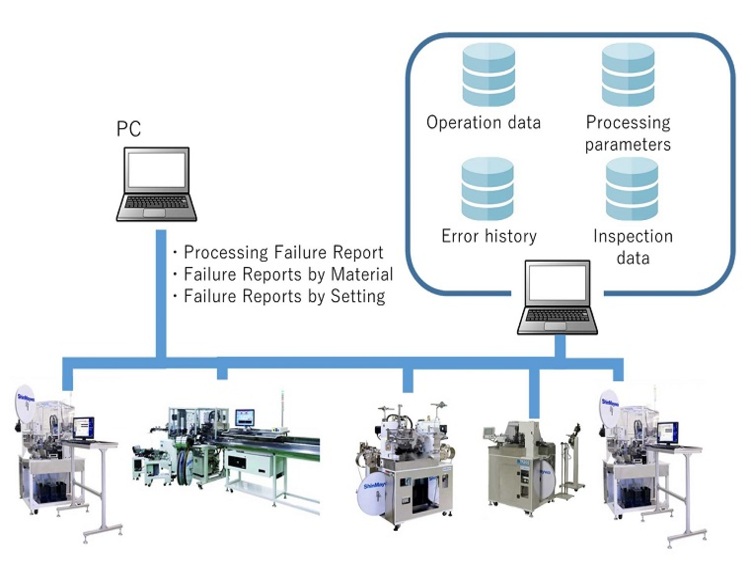

Remote Monitoring System

The system can provide a variety of support using data from automatic wire processor. Information from each plant or production line can be collected in single PC.

- Monitoring System

- Monitoring of the Produced amount, Operating time, Downtime, Failure time, Error count, Defective pieces, etc. Report of Operation rate or Achievement rate can be created.

- Analyzing system (RMA-01)

- The system can support investigation of defects in process by recording the details of machine stoppages and defects.

Defect report is displayed based on materials or machine parameter.

Contact Information

Click here for product inquiries.