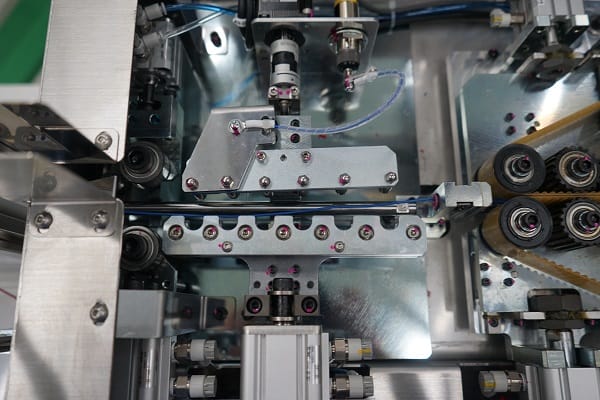

TRD701 / TRD711

Both-ends crimping machine TRD701 (CE Marking)

Both-ends crimping machine with seal insertion unit TRD701WPA (Machine mounted with both-ends 3-module seal unit) (CE Marking)

Both-ends crimping machine with single-end seal insertion unit TRD701WPSA (Machine mounted with single-end 3-module seal unit) (CE Marking)

Both-ends crimping machine TRD711

Both-ends crimping machine with seal insertion unit TRD711WPA (Machine mounted with both-ends 3-module seal unit)

Both-ends crimping machine with single-end seal insertion unit TRD711WPSA (Machine mounted with single-end 3-module seal unit)

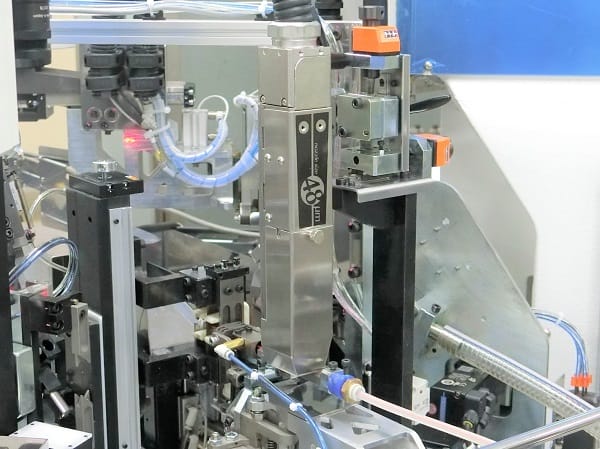

More productivity with high speed and precision processing

Wider production range, Flexible applications and Various sensors

Automatic wire changer

- Next wire ready without stopping the production

- Wire change by simple PC operation

Servo-Controlled Wire Straightener

- Automatic adjustment of the wire straightener rollers

- Straightener parameters registered in the wire database

Nozzle-less Clamp

- No nozzle change for different wire size

- Fully automatic wire change

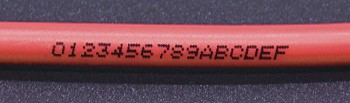

Inkjet Marking

- Integrated wire marking system synchronized with wire measuring

- Maximum 6m/s high speed processing

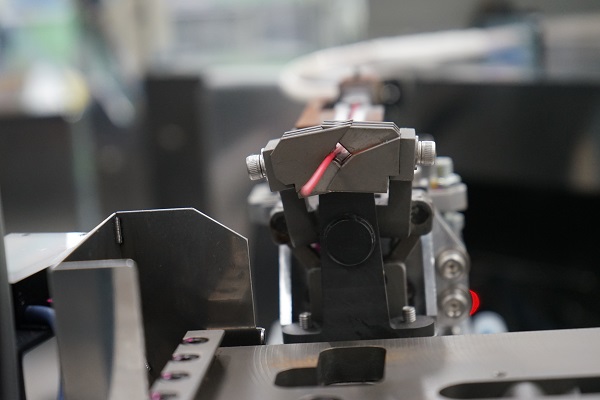

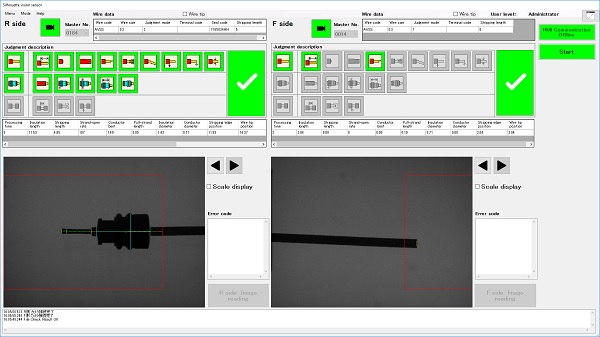

SVS (Silhouette Vision Sensor)

- Defect detection by silhouette image

- Stripping condition and rubber seal position

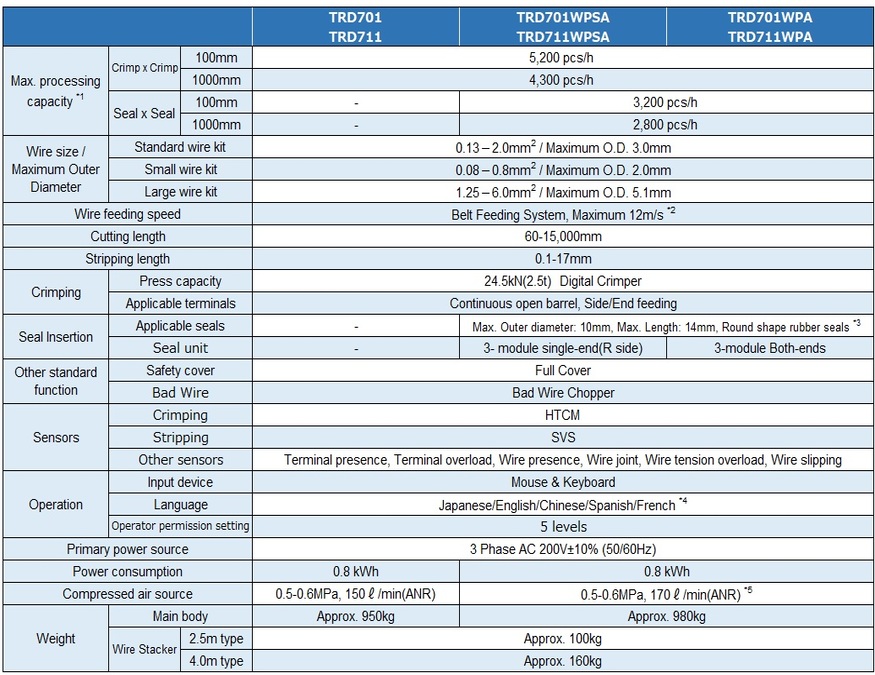

Standard Specification

- *1Capacity might change depending on the processing conditions and parameter.

- *2Feeding speed needs to be adjusted depending on wire condition and processing requirements.

- *3For wire combinations, please contact us.

- *4Please contact us for the other language.

- *5The air volume does not include the consumption of Parts Feeder.

Outside Dimensions

Contact Information

For product inquiries, please click the button below

Search for other products and services