TRD602

Model TRD602 Series Terminating Machine

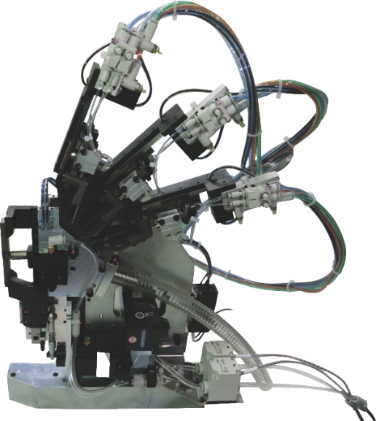

Both-ends crimping machine TRD602

Both-ends crimping machine with single-end seal insertion unit TRD602WPSA (Machine mounted with single-end 3-module seal unit)

Single-end tinning and single-end crimping machine THR602

Single-end tinning and single-end crimping machine with seal insertion unit THR602WPSA (Machine mounted with single-end 3-module seal unit)

The latest model for both-ends crimping, single-end tinning and single-end crimping, single-end tinning and single-end crimping with seal insertion

New interface and digital press for less setup time

Utilizing the processing unit from previous models for reliable process with high speed

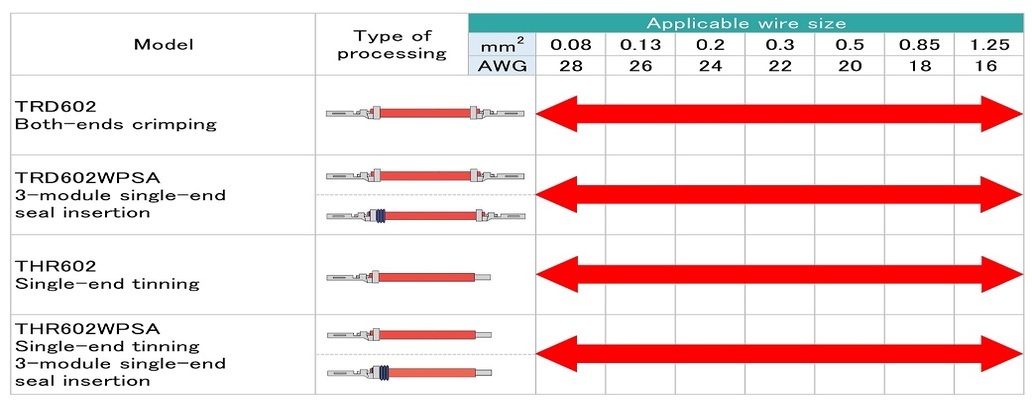

Wire size application table

- *The mm2/AWG conversion of the wire size is for reference only.

- *Some wires are difficult to process.

- *Please contact us when special wires need to be processed.

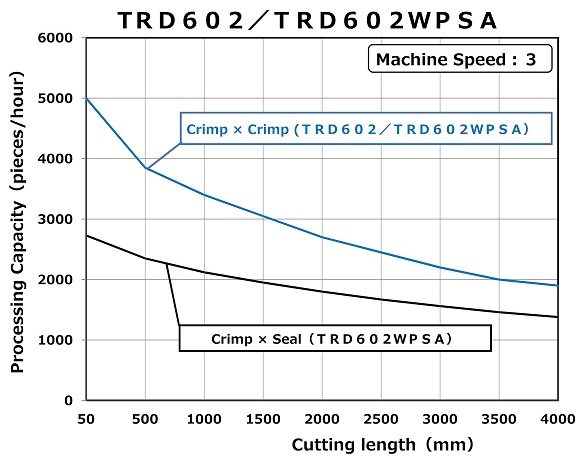

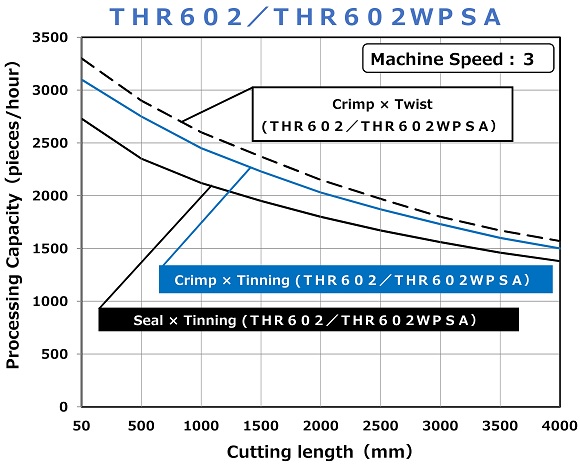

Processing capacity table

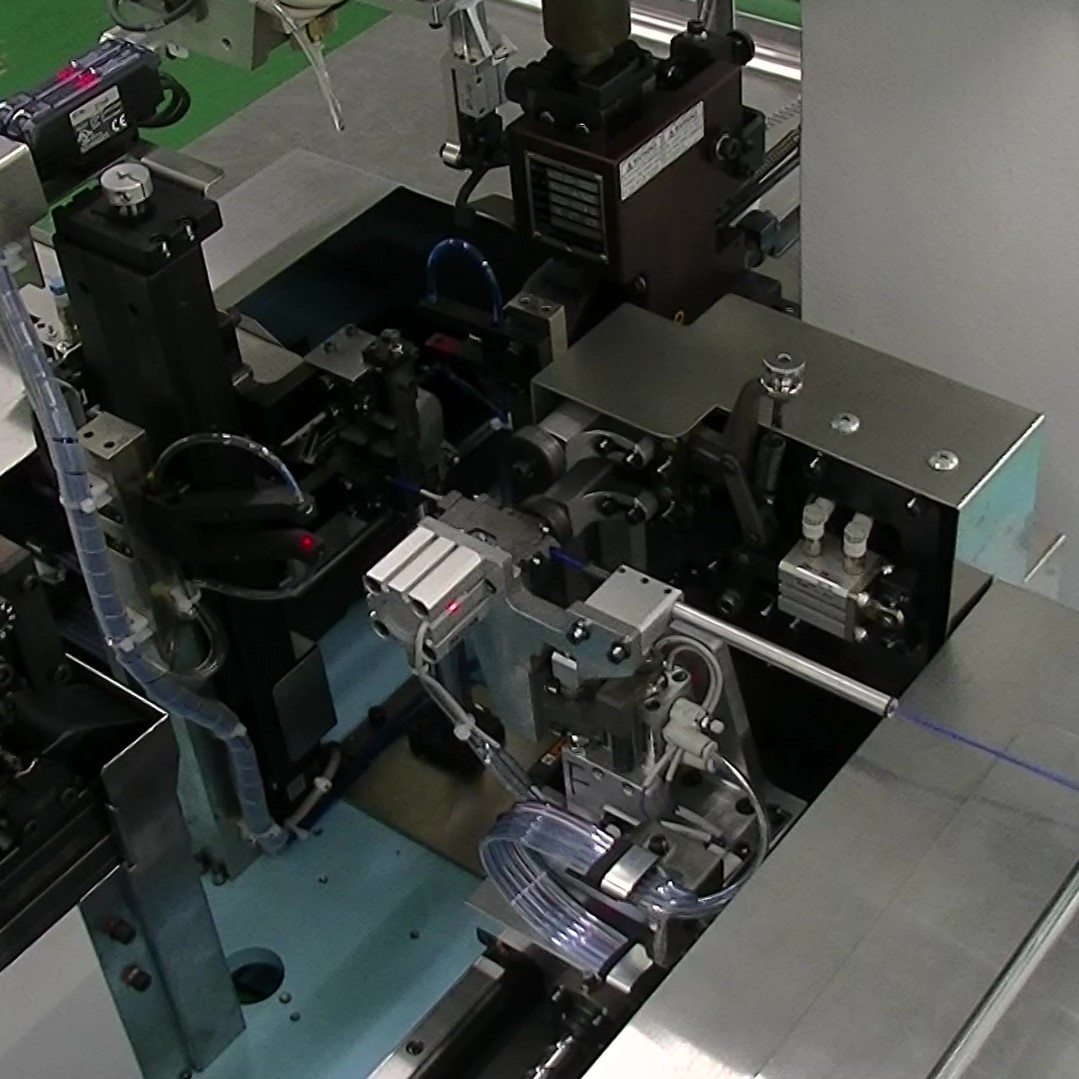

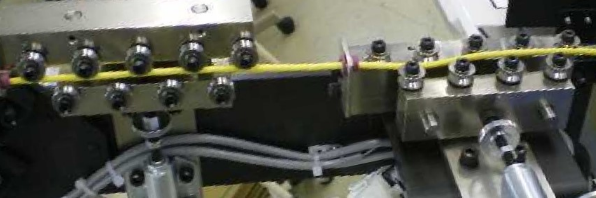

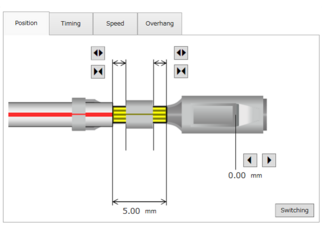

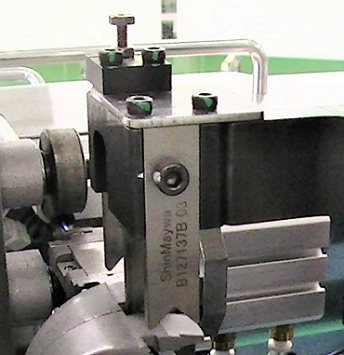

XY driving unit, Roller feeding, Pre-feeder

- Stable process for various wires using Pre-feeder, XY driving unit and Roller feeding

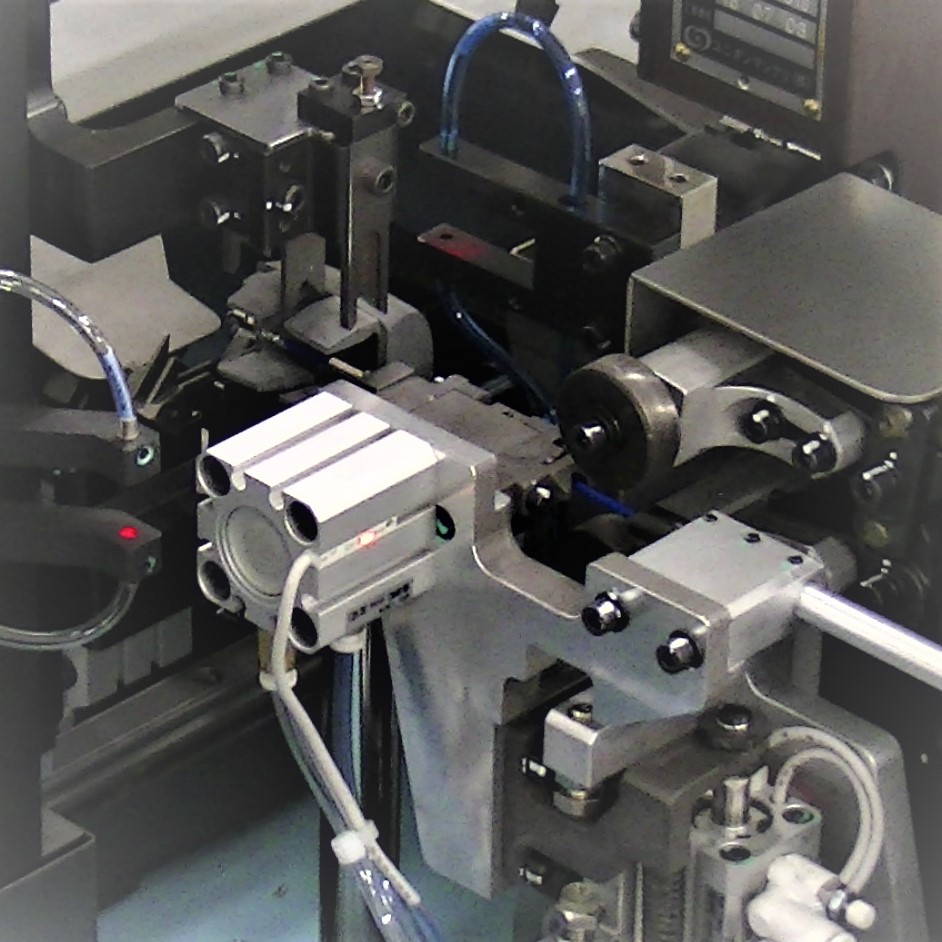

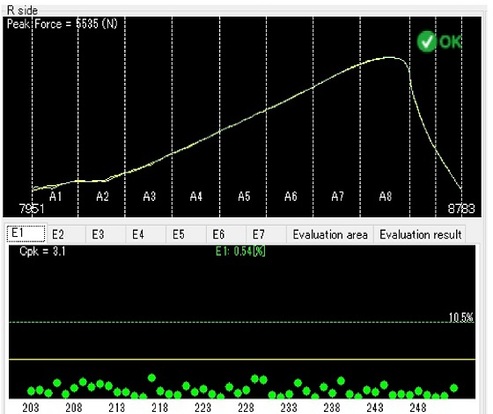

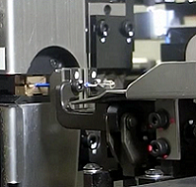

Original Terminal Crimping Monitor (HTCM)

- Adopts our original high-precision version type, terminal crimping monitor.

- A new method of crimping process monitoring improves the ability to detect defects such as core wire breakage.

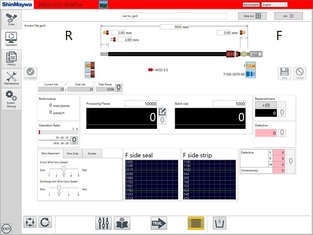

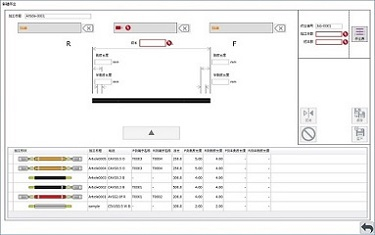

New interface

- Better usability with big monitor

- Easy work data preparations by guidance system

- Good for every level of operators

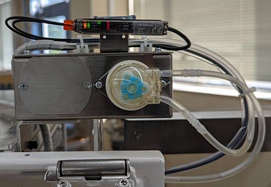

3-module seal insertion unit (WPSA)

- Equipped with a single-end 3-module seal unit (WPSA), which has a rich track record of processing.

- Adopting a cassette system contributes to easy parts feeder replacement and expanded work space.

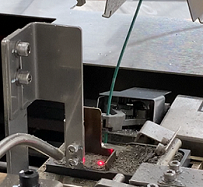

New tinning unit

- Less tin consumption

- Laser tin level sensor and automatic flux supply

Each unit

Standard Specification

| Model | TRD602 | TRD602WPSA | THR602 | THR602WPSA | |

|---|---|---|---|---|---|

| Max. processing capacity cutting length 50mm |

5,000 pcs/h (Both-ends crimping) |

2,700 pcs/h (Both-ends crimping and Single-end seal insertion) |

3,000 pcs/h (Single-ends crimping and Single-end tinning) |

2,700 pcs/h (Single-ends crimping and seal insertion and Single-end tinning) |

|

| Wire size / outer diameter | Size: AWG 28 - 16 / 0.08 - 1.25 mm2 Outer diameter:Φ0.8-3.2 | ||||

| Press capacity | 24.5kN (2.5t) digital crimper | ||||

| Stripping length | 2 - 16mm (0.01mm intervals) | ||||

| Cutting length | 50 - 9,999mm (1mm intervals) | ||||

| Operation language | Japanese, English, Chinese, Thai, Vietnamese | ||||

| Power supply | 3-phase AC200V (50/60Hz) ± 10% | ||||

| Compressed air source | 0.5 - 0.7MPa 130L/min(ANR) |

0.5 - 0.7MPa 150L/min(ANR) |

0.5 - 0.7MPa 140L/min(ANR) |

0.5 - 0.7MPa 150L/min(ANR) |

|

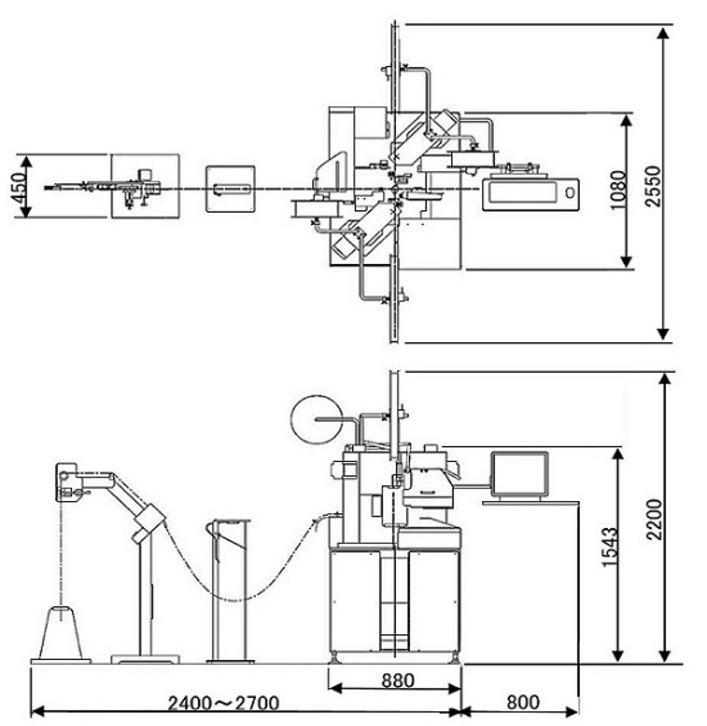

| Dimensions | 1,080W×880L×1,543H mm (main body only, excluding protrusions) | ||||

| Weight | Main body | Approx. 670kg | Approx. 700kg | Approx. 670kg | Approx. 700kg |

| Pre-feeder | Approx. 40kg | ||||

- *1Capacity might change depending on the processing conditions and parameter.

- *2Feeding speed needs to be adjusted depending on wire condition and processing requirements.

- *3For wire combinations, please contact us.

- *4Please contact us for the other language.

- *5The air volume does not include the consumption of Parts Feeder.

Outside Dimensions

Contact Information

For product inquiries, please click the button below

Search for other products and services

ShinMaywa INSIGHT

March 09, 2022