Our company's "R&D on large integrated molded aileron'' application was selected for NEDO's "Green Innovation Fund Project/Next Generation aircraft Development Project.''

November 9, 2021

ShinMaywa Industries, Ltd. Ltd. (Head Office: Takarazuka City, Hyogo Prefecture, President and CEO Isogawa Tatsuyuki) is a Green We have received official notification that the following themes we applied for have been selected by the Innovation Fund.

Theme:

"Research and development of a large, integrally molded aileron using thermoplastic composite material that enables a weight reduction of more than 30% compared to a metal-structured aileron"

Following the publication of NEDO on November 5th, we would like to provide an overview of the selection results.

1. About the “Green Innovation Fund Project”

- * Quoted from NEDO website

- 1 Purpose/Overview

In order to achieve carbon neutrality set for 2050, NEDO has created a 2 trillion yen fund and will continue to support companies and others committed to ambitious goals for 10 years, from research and development and demonstration to social implementation. and support.

- 2 Goals

- Achieving 2030 goals on a project-by-project basis

- CO2 reduction effects and economic ripple effects associated with the above

- 3Support target

These are priority areas for which action plans have been formulated in the Green Growth Strategy, and support will be focused on areas that have significant policy effects and require long-term continuous support with an eye toward social implementation.

- * For details, please check the following news release regarding this matter on the NEDO website.

2. Themes that our company will tackle in the “Green Innovation Fund Project/Next Generation aircraft Development Project”

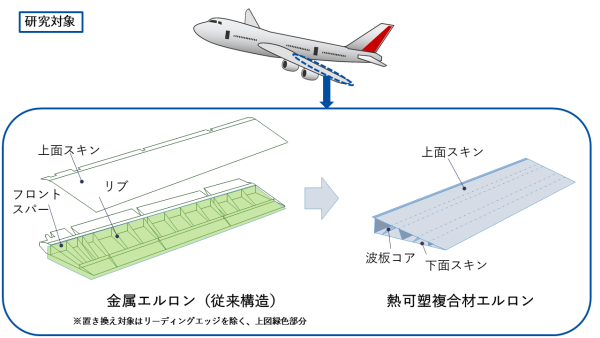

| (1) Overview | It was selected as part of the "development of complex shapes and dramatic weight reductions for major aircraft structural parts." Regarding civil aircraft parts, ``Ailerons (auxiliary wings attached to the outside of the trailing edge of the main wing)'', we have developed ``Ailerons'' that can reduce the weight by more than 30% compared to the structures (made of metal) currently manufactured and sold by our company. Research and development of new construction methods for large-scale integral molding using thermoplastic composite materials. |

|---|---|

| (2) Period (planned) | FY2021-FY2025 (5 years) |

| (3) Significance of this research | Utilizing the characteristics of thermoplastic composite materials such as light weight, high strength, and high production efficiency, we are developing energy-saving technology that improves aircraft performance and fuel efficiency by reducing the weight of parts and reducing the energy load generated in the manufacturing process. Through development, we will contribute to the realization of a decarbonized society. |

Contact Information

For news organizations

ShinMaywa Industries, Ltd. Public Relations/IR Department Corporate Planning Headquarters

1-1 Shinmeiwa-cho, Takarazuka, Hyogo, 665-8550, Japan

About products

ShinMaywa Industries, Ltd. Sales Planning Department Aircraft Division

078-412-9151

(Aircraft Division Representative Number)

1-1-1 Ogi, Higashinada-ku, Kobe, Hyogo, 658-0027, Japan

The information published in this content is current as of the date of publication.

Please note that this information may differ from the latest information due to changes in our group's business strategies and organization.