SCREEN/Features

SB series

SB series Wedge wire screen

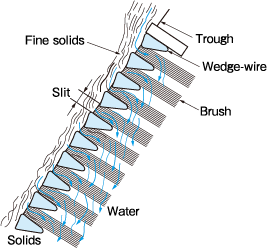

SB/S-series are wedge wire screen for removing a solid contained in waste water. SB series: Non-clogging operation by built-in rotation brush.S series: Easy and economical operation by simple structure.

Applications

- Suspended solids objects removal in sewage treatment plant.

- Material recovery and waste water treatment process in the paper factory.

- Waste water treatment process in the food, fiver, and chemical industry.

- Separation and selection in mining water treatment facilities.

Always clean

The driving power of the rotating brush is 100W. Moreover, the intermittent operation keeps power consumption lower.

Low running cost

The rotating brush equipped behind the screen automatically washes and always keeps the screen clean.

High screening effect

Clean slit kept by rotating brush maintain the higher screening effect.

Easy washing

The water separated by screen hits the rotating brush,which moves horizontally along the slit,and is emitted from the back of screen by centrifugal force.

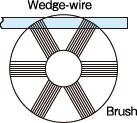

Structure

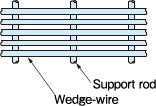

- SS screen consists of feeding box, body and screen. Screen is composed of wedge wires and support rods which are welded together. Main parts of SS screen are made of stainless steel.

Detail view

- Wedge wire and support rod are one structures by special welding, there is no deviation of a slit.

- Welded downward (slanting) to wedge wire and support rod, a solid and water are effectively separable.

- Rotating brush is installed behind the screen, and timer controlled.

- The controller is built into water-proof operation panel.

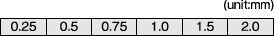

Slot size

- *Size for 0.2, 0.3, 0.4, 0.6, 0.9,can also be manufactured.