[Series] How the US-2 is made (6)

Close coverage by a professional writer

Airframe assembly

—Efficient assembly using modular design

Continuing from the previous issue, this issue introduces the airframe assembly process of the US-2.

The previous issue talked about the semi-monocoque structure, in which parts are assembled to form a framework with frames (ring frames) and stringers (reinforcement material), and then the skin (outer panels) is attached to the framework. For a large aircraft such as the US-2, the framework is divided into multiple blocks and built in simultaneously, which are all assembled to form the aircraft shape at the end. This is called the modular design.

Modular design significantly streamlines the process.

For example, support is sometimes needed from the backside when riveting the skin. With modular design, workers can easily go around to the backside to provide support, and they can also easily communicate with each other and give signals.

Another advantage is that the work can be performed simultaneously at the plant of subcontracting companies (suppliers) that have the required technical capabilities. In fact, large components of the airframe, such as the front middle fuselage, are also manufactured by subcontracting companies. Approximately 1,400 companies participate in the production of the US-2 including electronic equipment and other onboard components.

(1) This is the strut for the float (which hangs from the main wing). To minimize aerodynamic drag, even the slightest unevenness of the surface is completely eliminated after riveting.

(1) This is the strut for the float (which hangs from the main wing). To minimize aerodynamic drag, even the slightest unevenness of the surface is completely eliminated after riveting. (2) This is the front edge of the wing. This section also consists of the frames, stringers, and skin. Fuel and hydraulic lines and electrical wiring will be routed through the inside after this section.

(2) This is the front edge of the wing. This section also consists of the frames, stringers, and skin. Fuel and hydraulic lines and electrical wiring will be routed through the inside after this section. (3) This is the bilge, which is the boat part that ordinary aircraft do not have. The structure is stronger than that of ordinary aircraft to withstand the high water pressure during takeoff and landing.

(3) This is the bilge, which is the boat part that ordinary aircraft do not have. The structure is stronger than that of ordinary aircraft to withstand the high water pressure during takeoff and landing.

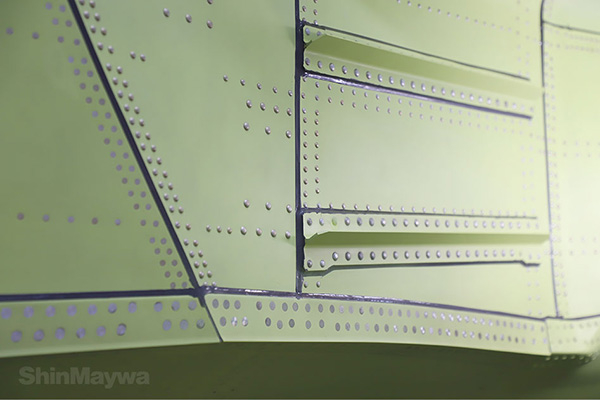

(4) The parts that is exposed to seawater are also securely sealed for waterproofing. Flat-head rivets (countersunk rivets) are used for part where low aerodynamic drag is required, and round rivets are used for areas that need to be strongly secured.

(4) The parts that is exposed to seawater are also securely sealed for waterproofing. Flat-head rivets (countersunk rivets) are used for part where low aerodynamic drag is required, and round rivets are used for areas that need to be strongly secured. (5) The main wings are being built. They also have a semi-monocoque structure. This part has a very solid construction since the entire airframe hangs from this part during flight. The inside is also used as a fuel tank.

(5) The main wings are being built. They also have a semi-monocoque structure. This part has a very solid construction since the entire airframe hangs from this part during flight. The inside is also used as a fuel tank. (6) US-2 is manufactured not only by ShinMaywa but also with the participation of many subcontracting companies. Here, the front middle fuselage manufactured by another company is being delivered to the Konan Plant in the middle of the night.

(6) US-2 is manufactured not only by ShinMaywa but also with the participation of many subcontracting companies. Here, the front middle fuselage manufactured by another company is being delivered to the Konan Plant in the middle of the night. (7) This is the front middle fuselage. Similar to passenger aircraft, it is pressurized and oxygen masks are not required at high altitudes.

(7) This is the front middle fuselage. Similar to passenger aircraft, it is pressurized and oxygen masks are not required at high altitudes. (8) This is the horizontal stabilizer. The worker is standing where the vertical tail will be mounted.

(8) This is the horizontal stabilizer. The worker is standing where the vertical tail will be mounted.

ShinMaywa Industries has inherited the expertise of flying boat design and manufacturing from Kawanishi Aircraft Company, and many companies have applied their own technologies in accordance with the design by Kawanishi Aircraft Company. It can be called the fruit of Japanese technology!

Writer Hidenori Itakura

- *This series is produced and published with the permission of the Ministry of Defense. Please do not reproduce the content and images of this series.