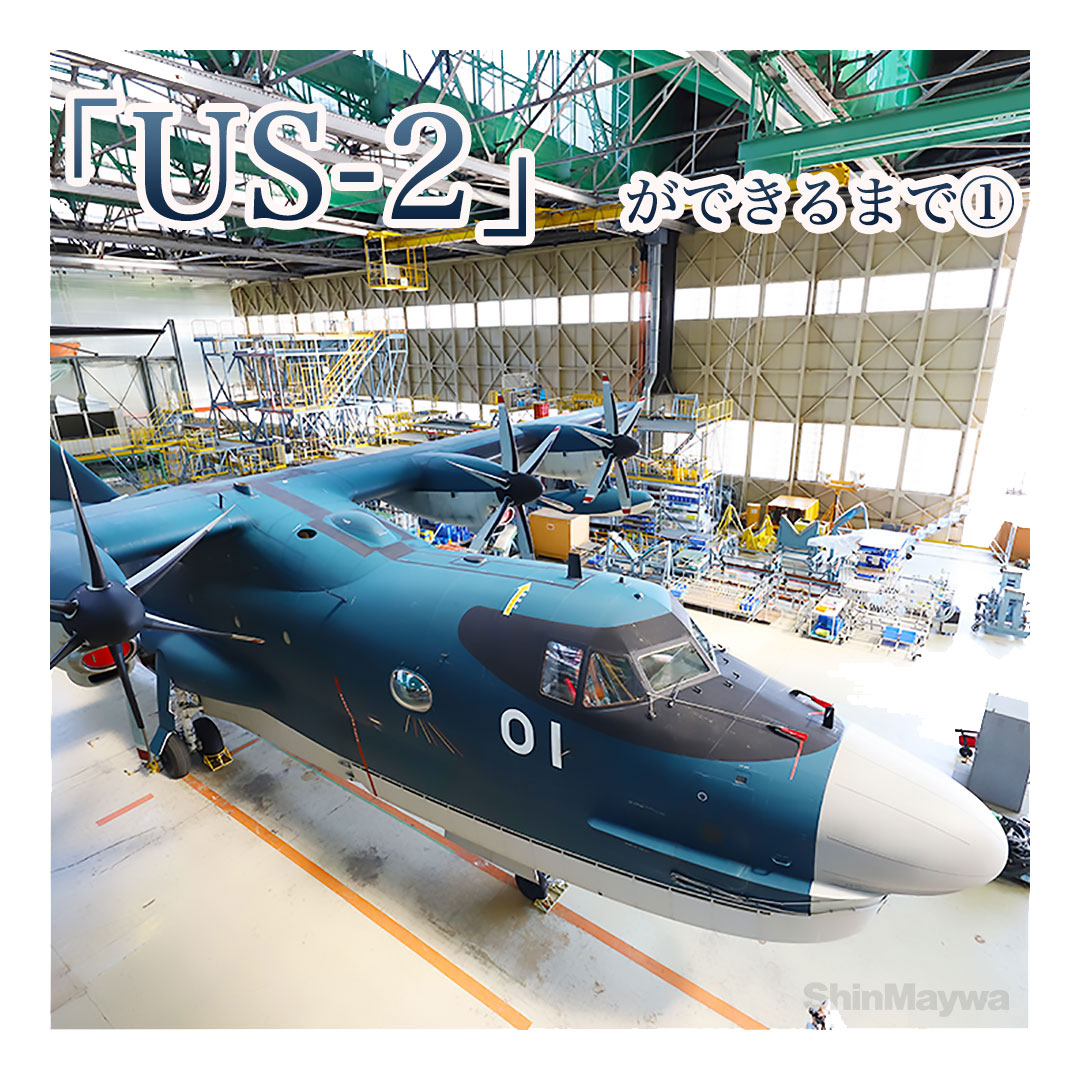

[Series] How the US-2 is made (1)

Close coverage by a professional writer

Cutting out the parts

—The US-2 is mostly made of aluminum

A professional writer closely covered the manufacturing process of the world’s highest-performance amphibian aircraft US-2 and the reports will be serialized.

Higashinada Ward in Kobe City, Hyogo Prefecture is a place known for having many sake breweries of famous sake producers. The Konan Plant of ShinMaywa Industries, where the US-2 is manufactured, is located in such a location.

Usually, aircraft plants are built next to a runway. However, this plant is for amphibian aircraft, which can take off and land on water and does not require a runway. Konan Plant is located next to the ocean and new amphibian aircraft take off and land on water off the coast of Kobe. Many local residents do not know that aircraft are manufactured at this plant as they do not see any runways in the vicinity.

Konan Plant manufactures the US-2 under the commission of the Ministry of Defense. The hull (the fuselage of an amphibian aircraft) and most wing parts, such as the main wings and tail fins, are manufactured and assembled with other parts and equipment manufactured by our partner companies around the world.

In this issue, we will introduce the initial manufacturing phase of the US-2.

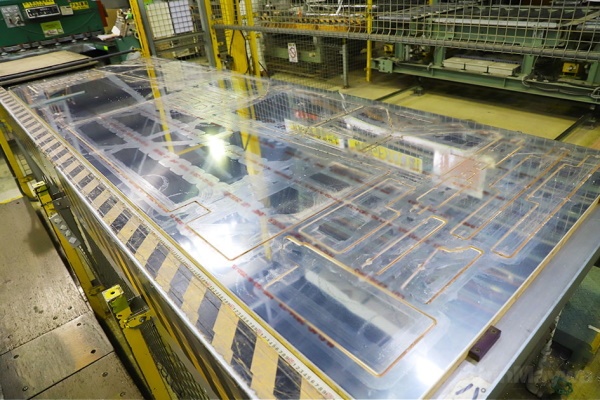

The initial states of the US-2 is aluminum sheets and blocks

Most aircraft use aluminum alloys for the majority of their fuselages in order to achieve both lightness and strength. Materials used in the US-2 are specified in detail. For example, several types of aluminum alloys are used depending on the required strength. The first manufacturing phase of the US-2 involves cutting and machining parts from sheets and blocks of several types of aluminum alloys produced by material manufacturers.

A machine called an NC router is used for cutting parts from aluminum alloy sheets. Several to dozens of "bare parts" can be cut from a one sheet by entering the data into the NC router. In the next step, craftsmen drill holes and bend this part element almost by hand to create the part's shape.

Parts produced in this process can be hardened through heat treatment (explained in the next issue). In the case of the parts that require higher strength, aluminum alloy blocks are machined instead of using thin sheets. These parts are also produced by hand using machine tools such as a general-purpose milling machine and NC lathe.

Some may be surprised to find that there is more manual work in the manufacturing process than expected. But this is the most effective way. Since most parts are made only small numbers every few years, hand work by skilled craftsmen is less costly and more efficient than having a lot of equipment that can automatically mass-produce parts. By the way, even the major overseas aircraft manufacturers also rely on manual labor for much of their manufacturing processes. It's a lot of work to build an airplane, isn't it?

Writer Hidenori Itakura

- *This series is produced and published with the permission of the Ministry of Defense. Please do not reproduce the content and images of this series.