Products

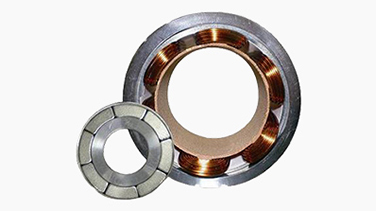

We can also propose customized designs according to your requests from standard motor/driver products.

Product Lineup

Contact Information

Click here for product inquiries.

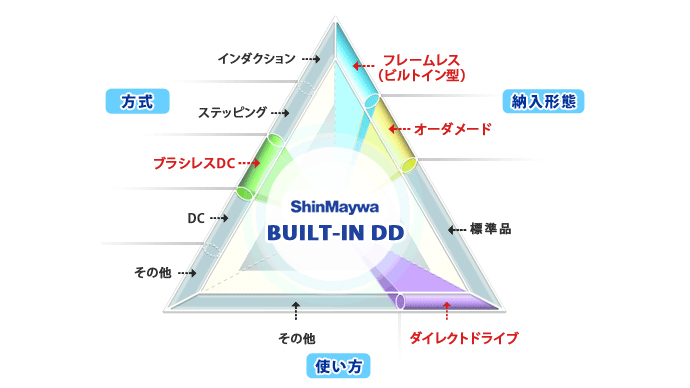

Please consider ShinMaywa 's "BUILT-IN DD series" for new drive system applications.