Development of a "Refuse Collection Operation Efficiency System" using garbage compactor trucks

By applying digital transformation (DX) to address issues such as labor shortages and knowledge transfer,

we aim to enable refuse collection work to be performed at the same level as veteran workers, regardless of experience or tenure.

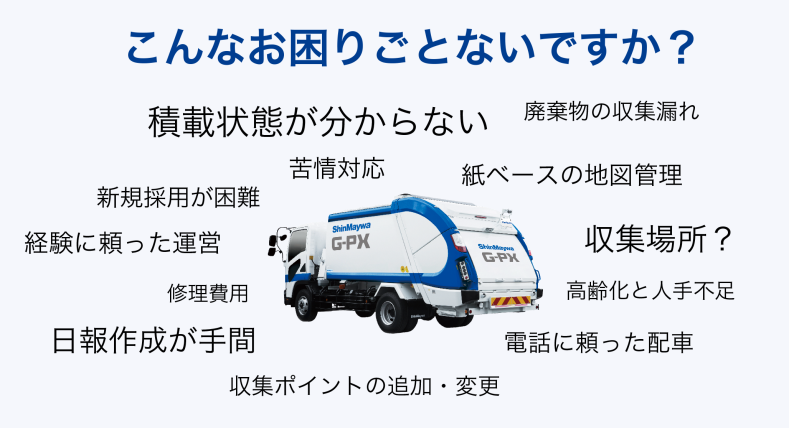

Background of development

The basic means of communication for sudden route changes, support arrangements, etc. is by telephone.

The amount of waste loaded depends on the driver, and dispatching depends on the experience of the operator and driver.

Refuse compactor trucks are used to collect various types of waste from homes and businesses, and are operated on the premise that they will travel along predetermined routes. However, in reality, the amount of waste to be collected and traffic conditions vary depending on the day of the week and time of day, so it is necessary to change routes and arrange for additional vehicles to be used accordingly. Furthermore, efficient collection requires coordination and know-how between drivers and operators, and this communication is mainly carried out by telephone.

Resolving the issues of labor shortages and know-how transfer is a challenge facing the entire industry

The waste collection industry is facing a long-standing labor shortage, but is also facing concerns about a further labor shortage due to an aging population and the 2024 problem (a shortage of transportation capacity due to the setting of a cap on overtime work hours).Municipalities and businesses have been calling for measures that would allow anyone, regardless of years of experience, to operate refuse compactors efficiently.

ShinMaywa's solution

"Refuse compactors and buses have one thing in common: they run according to a daily schedule and stop at set locations. Amidst calls for labor shortages and work style reform, ShinMaywa, a leading manufacturer of special purpose truck, boasts a 60% domestic market share for refuse compactors, and LECIP, Japan's only total supplier of electrical equipment for buses, offering a variety of products and systems to support bus operations, including bus location systems, have agreed to combine their technologies and knowledge and have begun joint development of a "Refuse Collection Operation Efficiency System" with the aim of achieving efficient and sustainable waste collection and transportation.

What is the "Refuse Collection Operation Efficiency System"?

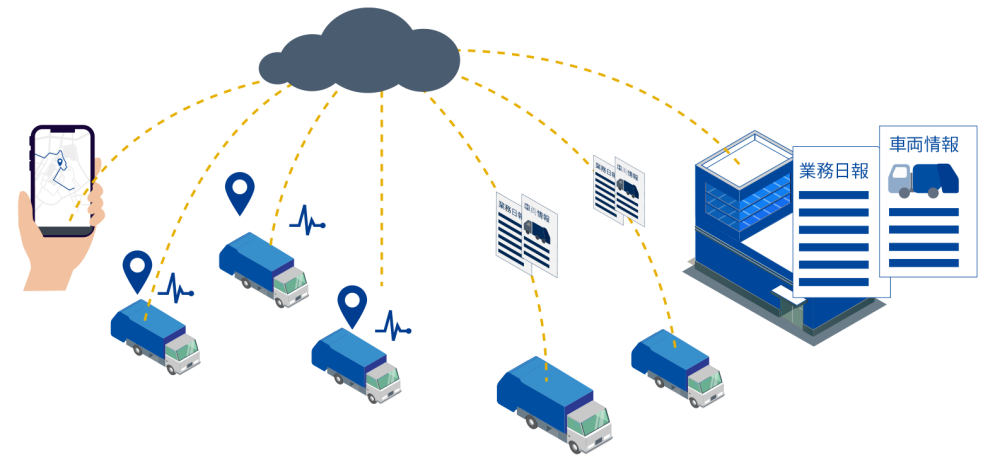

This system utilizes a variety of data collected in real time from refuse compactors equipped with on-board communication devices, including location information, operation information, loading status, and collection history, to improve the work efficiency of both operators and drivers.

Previously, determining the amount of waste loaded onto refuse compactors relied on the driver's experience, and the situation was shared with the operator via telephone, but with the introduction of this system, operators can grasp the location and operating status of multiple vehicles in real time, making it easier to arrange vehicle dispatches and contact drivers.The system also has a comment function that can display route guidance incorporating know-how and on-site rules, enabling veteran-level work to be carried out regardless of work experience.

Furthermore, it fully supports the efficiency of waste collection operations by automatically creating daily reports after collection work and notifying users when maintenance is required for refuse compactors.

(For more details, please click on the image below to visit the special website. It introduces the service from three perspectives: "operators," "drivers," and "managers"! (The video is in Japanese only.))

[Demonstration testing currently underway, with the aim of launching the service within 2025]

We are conducting demonstration experiments of this "Refuse Collection Operation Efficiency System" using operating refuse compactor trucks with the cooperation of companies engaged in waste collection and transportation businesses (for details, please contact the contact information at the end of this document).

| Driver Assistance | Operator Support |

|---|---|

|

|

| Driver Assistance | Operator Support |

|---|---|

|

|

| Company name (Head Office location) | Kawasei Co., Ltd. (Kawasaki City, Kanagawa Prefecture) |

|---|---|

| Refuse compactor trucks used / number | Rotary blade type refuse compactor trucks (2-3 ton class) 3 units |

| Demonstration experiment area | Kawasaki City |

| Refuse compactor trucks collection target | General household waste, general business waste |

| Experiment period | May 12-25, 2025 |

| Company name (Head Office location) | Midac Holdings Co., Ltd. (Hamamatsu City, Shizuoka Prefecture) |

|---|---|

| Refuse compactor trucks used / number | Press type refuse compactor trucks (3-4 ton class) |

| Demonstration experiment area | Hamamatsu City |

| Refuse compactor trucks collection target | General business waste |

| Experiment period | June 2-30, 2025 |

Comments of Development Site

Special Purpose Truck Division

Mr. Nishimura from the Sales & Marketing Department, and Mr. Kiyokami from the New Business Development Department

As a pioneer in the manufacture of refuse compactor trucks in Japan, we have been a close partner to the waste collection industry for over 70 years, developing products while listening to the needs of our customers since we began production of refuse collection trucks in 1954. These efforts have been so successful that one out of every two refuse compactor trucks on the road in Japan is now made by ShinMaywa.

Since joining the company, we have been involved in sales, development, and design of special purpose truck, and especially since we have been involved in refuse compactors for a long time, we have been working together in sales and development to face the challenges of waste collection in that era. As a manufacturer with the top market share, we have led the market by providing not only the performance, functions, and capabilities of refuse compactors, but also value-added products such as labor-saving, fire prevention, odor control, and measures against entrapment accidents, ahead of our competitors. In recent years, however, many customers have presented challenges, especially "labor shortage" and "know-how transfer", We have always wondered if we could contribute to resolving these issues.

In fact, we were hearing more and more from our customers that their operations were becoming sluggish, and while we were searching for ways to utilize the information obtained from refuse compactors to solve their problems, we met with LECIP, which led to the development of this system.

We received the following positive comments from company managers, operators, and drivers who cooperated in the demonstration experiment, and we are working to complete the system to help drivers, operators, and managers improve their work efficiency and reduce their workload.

We would like to contribute to society not only by contributing to our customers' business through the conventional "product" of refuse compactors, but also through "services" such as this system that can solve the problems of our customers' business in general. Through these efforts, we would be happy if as many people as possible would think again, "ShinMaywa is a company that supports our daily lives.

A Business Owner’s Testimonial

The most important benefit is that the vehicle's status and location information are clear at a glance, and the know-how of veterans is also visualized on the system, allowing everyone to share it. I also think that if we can promote the fact that there is no need to memorize routes, this will be a good tool for attracting talent.

An Operator's Testimonial

Information about problems and important points to note can be shared with all drivers simply by entering it into the system, and daily reports can also be entered by drivers on-site and returned, which has significantly improved work efficiency.

A Driver’s Testimonial

When I got home, I no longer had to memorize the next day's route, which I felt was a mental benefit.

現場の1日をDX化!「廃棄物収集業務効率化システム」