ターボブロワ遠隔監視サービス "KNOWTILUS" のビッグデータを活用した「AI見守りサービス」を開発

2020年11月02日

新明和工業株式会社(本社:兵庫県宝塚市、取締役社長 五十川 龍之)は、このたび、下水処理や工場排水処理などの水処理設備のばっきに使用するターボブロワ「TurboMAX」の遠隔監視を行うサービス "KNOWTILUS" の機能拡充とビッグデータを活用した「AI見守りサービス」を新たに開発し、11月2日から提供を開始します。

近年、少子高齢化による労働力不足への対応や労働環境の改善が求められるなか、多くの業界・業種でさまざまな取り組みが実践されています。生産工場内の排水処理施設や下水処理場なども同じ環境にあり、運転管理や維持管理における人手不足により、業務の高効率化・省人化が喫緊の課題となっています。

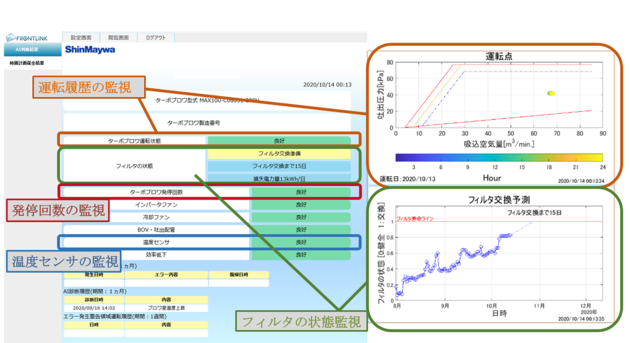

当社が2019年9月1日に発売したターボブロワ専用の遠隔監視サービス "KNOWTILUS" は、ターボブロワ本体に表示される運転画面を手元のパソコンやスマートフォンに表示させ、遠隔からの状態監視を可能にするもので、警報やエラー発生時は、関係者にエラー内容と対処方法を自動的にメール通知する機能を有し、早期発見によるダウンタイム短縮化が図れると好評を得ています。ターボブロワ向けでは初となるAI※1を活用した運転データの分析により、トレンドデータに基づきエラーの原因を推測できることが最大の特長で、懸案となっている設備管理業務の支援や予防保全による安定稼働を実現してきました。

- ※1「Microsoft Azure」を活用したAI/IoTによる遠隔監視システム

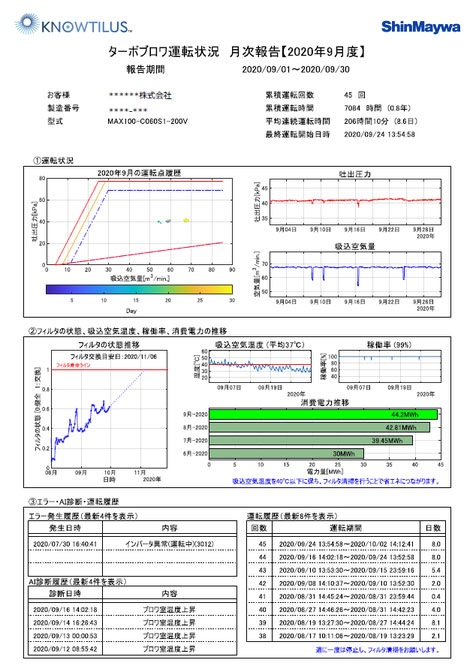

新たに提供を開始する「AI見守りサービス」は、これまで "KNOWTILUS" から取得した運転データを活用し、当社が、「日常点検」や「月報作成」等の一部の管理業務を代行するメニューで、メーカーである当社と、サービス専門会社である新明和アクアテクサービス株式会社が一体となり、突発的なトラブル発生を未然に防ぎ、設備の安定稼働をサポートするものです。これは、今般新規開発した独自のAIアルゴリズムにより、様々なデータの取得と分析を実現したもので、機械部品の故障を予兆して、補修部品の適正なメンテナンス時期が把握できるようになるなど、運営費用の削減や点検業務の更なる効率向上が期待できます。

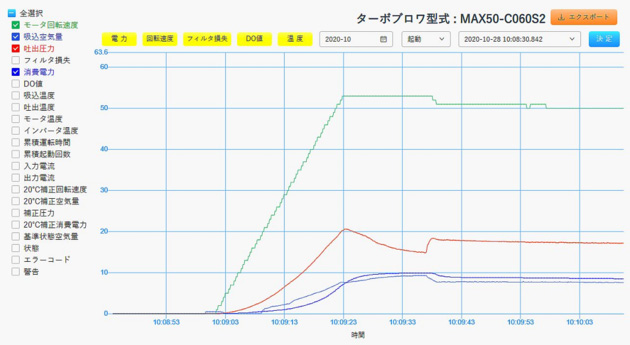

さらに、既存の遠隔監視サービス "KNOWTILUS" の機能を拡充し、起動時やエラーによる停止時の運転データを高精度で取得するイベントレコード機能を追加しました。これにより、Web画面上で圧力の変動やサージング領域への運転軌跡の把握が可能となり、エラーの原因特定・分類も容易に行えます。

当社は、たゆまぬ技術革新で、安心な社会と快適な暮らしを支え続け、人々の幸せに貢献することを経営理念に掲げております。ターボブロワや遠隔監視サービスのみならず、高効率性と高通過性を兼ね備えた水中ポンプや高効率ミキサを提供するなど、水処理機器の省エネルギー化に向けた製品の開発に注力するとともに、製品のライフサイクルをサポートするべく、新たにIoTやAIを積極的に取り入れたサービスの開発にも注力しています。これからも、各種水処理機器のさらなる高度化を具体化することで、社会に貢献してまいります。

"KNOWTILUS" は 新明和工業株式会社の登録商標です。KNOW(わかる)+NAUTILUS(オウムガイ=長寿命)の造語です。

"TurboMAX" は、TURBOMAX Co., Ltd.の商標または登録商標です。

1. AI見守りサービスの特長:

2.主要販売先

下水・排水処理場、生産設備

3.サービス開始日

2020年11月2日

本件に関するお問い合わせ先

報道機関の方

〒665-8550

兵庫県宝塚市新明和町1-1

製品について

流体事業部 事業企画部

〒230-0003

横浜市鶴見区尻手3-2-43

以上

このコンテンツに掲載している内容は、発表日現在の情報です。

これらの情報は、当社グループの事業戦略および組織の変更などにより、最新の情報と異なる場合がありますのでご了承ください。