-プロのライターが密着取材!

機体外部の艤装(ぎそう)です。動翼や車輪などを取り付けます。

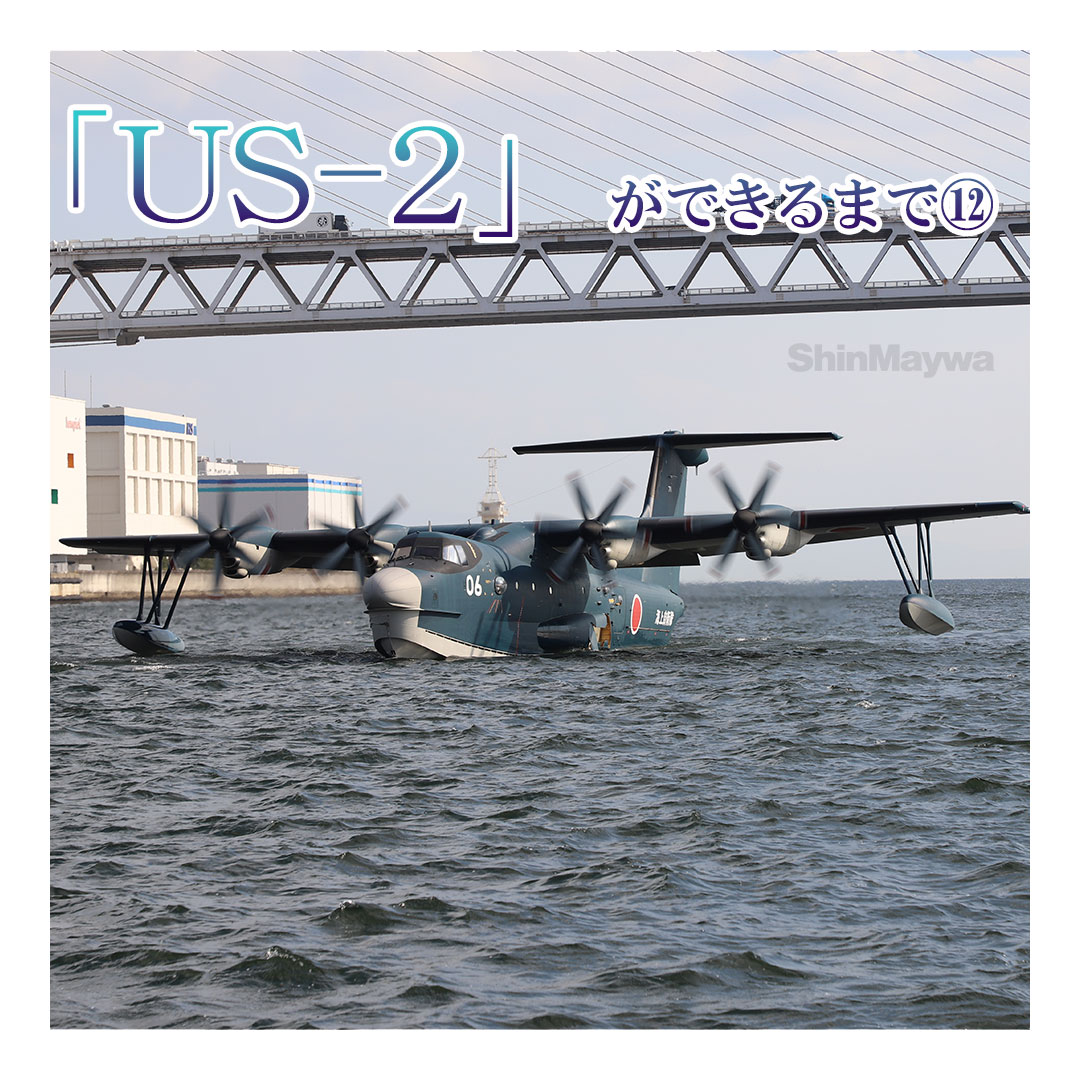

全塗装が終わった「US-2」に、機体表面の動翼やギア(降着装置)などの可動パーツを取り付けていきます。いよいよ艤装の最終段階にさしかかりました。

航空機は、エンジンの力で推進し、翼で揚力を発生させ、その揚力をエルロン(傾きを制御)やエレベーター(機首の上下角を制御)、ラダー(機首の左右の首振りを制御)といった動翼でコントロールして飛行します。離着陸水時には低速で揚力を高めるフラップやスラットも使い、滑走路での離着陸やスリップを通る際にはギアも出します。

艤装の終盤ではこうした非常に重要なパーツを取り付けていきます。大きく重いパーツが多く、また取り付けるためのボルトなどの付近には油圧の配管などもあるため、取り付け時に不用意に接触して損傷しないよう慎重に作業します。大きなフロートや、反対に小さなアンテナ類や放電索(飛行中に静電気を放電し、無線のノイズなど電磁波障害を取り除く装置)なども、機体の全塗装を効率的に行うために全塗装後のこの段階で取り付けられます。

こうしたパーツの中には協力会社でつくられているものもありますが、機体の全塗装後に取り付けるため、予め塗装された状態で甲南工場に運ばれてくるものもあります。この一事を見ても、非常に細かい組立の手順があり、その仕様やスケジュールに沿って機体が形づくられているのがわかります。

※艤装(ぎそう)・・・エンジンや機体内外の装備品を取り付ける工程のこと、または取り付ける装備品そのもの。

(1)艤装の最終段階で取り付ける部品たち。協力会社でつくられたものもあり、後ろの箱の中にも部品が入っています。

(1)艤装の最終段階で取り付ける部品たち。協力会社でつくられたものもあり、後ろの箱の中にも部品が入っています。 (2)艇底前部の「溝型波消し装置」の板。強烈な水圧がかかる部分ですのでチタン合金製です。

(2)艇底前部の「溝型波消し装置」の板。強烈な水圧がかかる部分ですのでチタン合金製です。 (3)機首のレドーム(レーダードーム)。線が数本見えるのは、雷から機体と電子機器を保護するライトニングアレスタ(被雷索)です。

(3)機首のレドーム(レーダードーム)。線が数本見えるのは、雷から機体と電子機器を保護するライトニングアレスタ(被雷索)です。 (4)フロート(浮舟)です。従来はアルミ製でしたが、「US-2」では複合材になり軽くなりました。

(4)フロート(浮舟)です。従来はアルミ製でしたが、「US-2」では複合材になり軽くなりました。 (5)ノーズギア(前輪)のカバーは複合材製。問題なく開閉するよう、仮留めして微調整します(作業員は帽子内に頭部保護具を装着しています)。

(5)ノーズギア(前輪)のカバーは複合材製。問題なく開閉するよう、仮留めして微調整します(作業員は帽子内に頭部保護具を装着しています)。 (6)離着水(離着陸)時に主翼前縁から前方にスライドして揚力をアップする「スラット」の機構部を取り付けています。

(6)離着水(離着陸)時に主翼前縁から前方にスライドして揚力をアップする「スラット」の機構部を取り付けています。 (7)飛行中に静電気を放電し、無線のノイズなど電磁波障害を取り除く放電索。こうした小さな部品も取り付けていきます。

(7)飛行中に静電気を放電し、無線のノイズなど電磁波障害を取り除く放電索。こうした小さな部品も取り付けていきます。 (8)ギアとギアカバー、波消し装置のカバー、フロート、スラット、エルロン、フラップ、ラダーといった部品が取り付けられ、いよいよ完成が間近になりました。

(8)ギアとギアカバー、波消し装置のカバー、フロート、スラット、エルロン、フラップ、ラダーといった部品が取り付けられ、いよいよ完成が間近になりました。

ライター 板倉秀典

- ※本連載の著作権等は新明和工業株式会社に帰属します。当社の許可なく内容や画像およびその一部を他の目的で転用することはご遠慮ください。

テーマから探す

#サステナビリティ

#社会インフラを支えています

#輸送

#3つの領域

#パーキングシステム

#都市

#環境

#保守

#研究開発

#新規事業

#流体

#川西機械製作所

#川西航空機

#新明和グループ

#AI

#水素

#US-2

#アップサイクル

#機械式駐車設備

#航空機

#特装車

#採用

#産機システム

#DDモータ

#環境システム

#自動電線処理機

#民間航空機事業

#航空旅客搭乗橋

#真空装置

#テールゲートリフタ

#ダンプトラック

#ごみ中継施設

#脱着ボデートラック

#アームロール®

#水中ミキサ

#リサイクルセンター

#水中ポンプ

#塵芥車

#飛行艇

#XU-M

#XU-L

#佐野工場

#US-1A改

#製品紹介

#エレパーク®

#ループパーク®

#パックスウェイ®

#US-1

#UF-XS

#PS-1

#甲南工場

#XU-S

#キャリア

#世界で活躍中

#US-2ができるまで

#マンガ暮らしを支える新明和

#真空成膜のお話

#歴史

#イベント

#お知らせ