[Series] How the US-2 is made (4)

Close coverage by a professional writer

Coating of parts

—Skilled craftsmen's skills are evident in the coating process

The surface treatment process was introduced in Part 3. After surface treatment, parts of the US-2 are carried into the coating booth within the specified time and coating is applied. The primary purpose of this process is to increase the parts’ corrosion resistance. The coating film protects the part’s surfaces from exposing to seawater etc.

The first coating applied in the coating booth is called the primer. The parts of the US-2 are painted with yellow primer. Therefore, a yellow US-2 will appear when the parts are assembled in the following process. US-2 has the image of dark blue and this is the color of the coating called the topcoat, which is applied to the entire airframe after assembly.

The yellow primer is so to speak the base coat. The number of coatings, film thickness (coating thickness), and other application methods are specified for the airframe surface and the components inside the US-2. The thickness of the coating is as thin as a human hair.

If the coating is thinner than this, corrosion resistance will be decrease. Conversely, if it is thicker, the airframe will be heavier than planned. This is another example of the difficulty of manufacturing amphibian aircraft. It must be lightweight but must be resistant to be exposed to the seawater. Therefore, this coating process is also done by hand, without relying on machines.

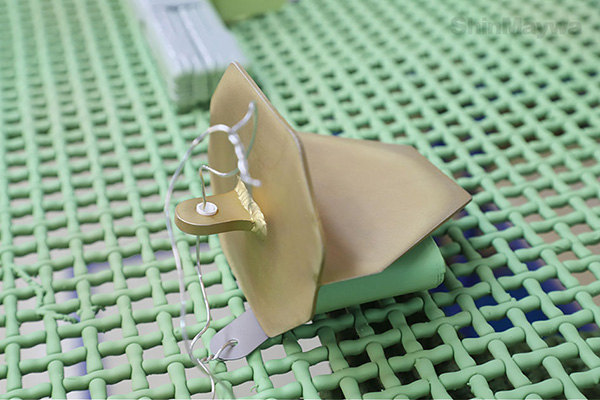

(1) Arrange the parts to be painted on the wire mesh. Since aluminum alloy parts are as light like as paper, a weight is placed at the back side so as not to be blown away by the spray gun.

(1) Arrange the parts to be painted on the wire mesh. Since aluminum alloy parts are as light like as paper, a weight is placed at the back side so as not to be blown away by the spray gun. (2) For the parts that have holes that are specified not to be coated, are paper is placed in the holes and masked as shown in this picture. This is a very detailed work. In addition, to avoid unevenness in coating, position tags and wires in advance.

(2) For the parts that have holes that are specified not to be coated, are paper is placed in the holes and masked as shown in this picture. This is a very detailed work. In addition, to avoid unevenness in coating, position tags and wires in advance. (3) The parts are placed on a lift and moved slowly to the coating booth.

(3) The parts are placed on a lift and moved slowly to the coating booth.

(4) This is the coating booth. A craftsman is coating them by hand because when it's done by machine, the coating film tends to be uneven.

(4) This is the coating booth. A craftsman is coating them by hand because when it's done by machine, the coating film tends to be uneven. (5) After coming out of the coating booth, the parts go into the dryer with their racks, where they are dried at the prescribed temperature and period after coming out of the dryer, the parts are turned over and transferred to the paint booth again for coating of the other side.

(5) After coming out of the coating booth, the parts go into the dryer with their racks, where they are dried at the prescribed temperature and period after coming out of the dryer, the parts are turned over and transferred to the paint booth again for coating of the other side. (6) This is how the coating of materials other than primer and coating of parts with special shapes are applied. The coating booth is designed to prevent fine particles of paint from floating in the air.

(6) This is how the coating of materials other than primer and coating of parts with special shapes are applied. The coating booth is designed to prevent fine particles of paint from floating in the air. (7) This is a booth for coating large parts. The Konan Plant also has a huge coating booth that can fit a whole entire US-2. This will be introduced in the second half of this series.

(7) This is a booth for coating large parts. The Konan Plant also has a huge coating booth that can fit a whole entire US-2. This will be introduced in the second half of this series. (8) Finished parts are checked one by one by human eyes and if uncoated corners or holes are found, touch up carefully with a brush. This work requires concentration and patience.

(8) Finished parts are checked one by one by human eyes and if uncoated corners or holes are found, touch up carefully with a brush. This work requires concentration and patience.

Writer Hidenori Itakura

- *This series is produced and published with the permission of the Ministry of Defense. Please do not reproduce the content and images of this series.