-プロのライターが密着取材!

部品の成型

職人技と化学が融合した工程です

アルミ合金の板材から切り出した「US-2」の部品は、どれもまだ真っ平らで、サイコロでいうとまだ展開図のような状態。これを曲げたり穴を開けたりして、指定された部品の形に仕上げていきます。

これには、板材を任意の曲線や角度に曲げられるプレスブレーキ、板材を金型に挟んで強い圧力をかけて一気に加工する液圧プレスなどの工作機械を使います。また、これらの機械では加工できない複雑な形状の部品については、熟練の職人がハンマーで叩いて手作業で曲げていきます。

こうした曲げ加工を行うには、柔らかく薄いアルミ合金のほうが適していますが、それでは「US-2」に必要な強度が出せません。

そこで行うのが、「熱処理」と呼ばれる工程です。一部のアルミ合金には、熱を加えたあと一定時間常温で放置すると硬くなる性質がありますので、強度が必要な部品についてはその性質を利用します。

具体的にはオーブンを使って定められた時間高温にさらし、その後常温に戻すことで硬くしていくわけです。このノウハウは、新明和が川西航空機として飛行艇を製造していたころから約80年間受け継いできた大切な財産です。

(1)プレスブレーキをつかえば、一瞬で目的の形に曲げられ、機体の表面のようなゆるやかな曲線にも加工可能。ただし、これには熟練の技が要求されます。

(1)プレスブレーキをつかえば、一瞬で目的の形に曲げられ、機体の表面のようなゆるやかな曲線にも加工可能。ただし、これには熟練の技が要求されます。 (2)液圧プレスです。金型に板材をセットし、奥に見えるプレス機で押し付けて目的の形状に加工します。同じ形のパーツの量産に向いています。

(2)液圧プレスです。金型に板材をセットし、奥に見えるプレス機で押し付けて目的の形状に加工します。同じ形のパーツの量産に向いています。 (3)「US-2」では、プレス機では加工できない形状のパーツが1カ所だけあり、熟練の職人がハンマーで丁寧に叩いて曲げていきます。

(3)「US-2」では、プレス機では加工できない形状のパーツが1カ所だけあり、熟練の職人がハンマーで丁寧に叩いて曲げていきます。

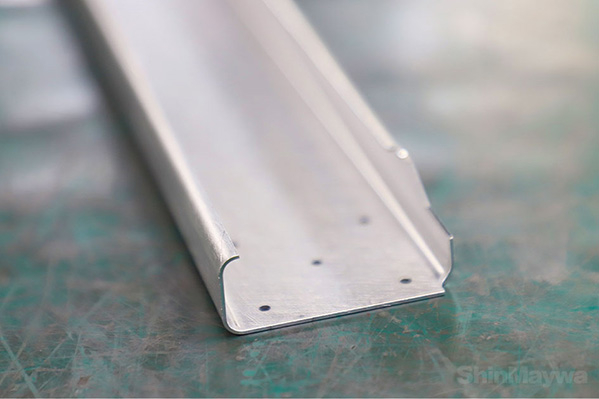

(4)プレスブレーキで加工した「US-2」の部品です。定められた順序通りに作業しないと、この形にはなりません。

(4)プレスブレーキで加工した「US-2」の部品です。定められた順序通りに作業しないと、この形にはなりません。

(5)アルミ合金を熱処理して硬くするための、いわばオーブン。扉の焦げが、高温になることを物語っていますね。社内の有資格者のみが扱えます。

(5)アルミ合金を熱処理して硬くするための、いわばオーブン。扉の焦げが、高温になることを物語っていますね。社内の有資格者のみが扱えます。 (6)熱処理が終わるとドアが開き、素材を入れたラックが出てきて、一気に薬液に浸して急冷します。このあとしばらくすると、素材は自然に強度を増していきます。

(6)熱処理が終わるとドアが開き、素材を入れたラックが出てきて、一気に薬液に浸して急冷します。このあとしばらくすると、素材は自然に強度を増していきます。

(7)曲げ加工が終わった「US-2」の部品です。次は、「表面処理」の工程に進みます。

(7)曲げ加工が終わった「US-2」の部品です。次は、「表面処理」の工程に進みます。

ライター 板倉秀典

- ※本連載は、防衛省の許可を得て制作、掲載しています。内容および画像の転載はご遠慮ください。

テーマから探す

#サステナビリティ

#社会インフラを支えています

#輸送

#3つの領域

#パーキングシステム

#都市

#環境

#保守

#研究開発

#新規事業

#流体

#川西機械製作所

#川西航空機

#新明和グループ

#AI

#水素

#US-2

#アップサイクル

#機械式駐車設備

#航空機

#特装車

#採用

#産機システム

#DDモータ

#環境システム

#自動電線処理機

#民間航空機事業

#航空旅客搭乗橋

#真空装置

#テールゲートリフタ

#ダンプトラック

#ごみ中継施設

#脱着ボデートラック

#アームロール®

#水中ミキサ

#リサイクルセンター

#水中ポンプ

#塵芥車

#飛行艇

#XU-M

#XU-L

#佐野工場

#US-1A改

#製品紹介

#エレパーク®

#ループパーク®

#パックスウェイ®

#US-1

#UF-XS

#PS-1

#甲南工場

#XU-S

#キャリア

#世界で活躍中

#US-2ができるまで

#マンガ暮らしを支える新明和

#真空成膜のお話

#歴史

#イベント

#お知らせ