Sales of high-performance remote monitoring system for automatic wire processors

February 12, 2021

ShinMaywa Industries, Ltd. (Head Office: Takarazuka City, Hyogo Prefecture, President and CEO: Tatsuyuki Isogawa) is conducting investigations and countermeasures for stoppage factors such as processing defects for customers using our automatic wire processors We commercialized a highly functional version of the remote monitoring system (hereinafter referred to as this system) to support the project, and began selling it in November 2020.

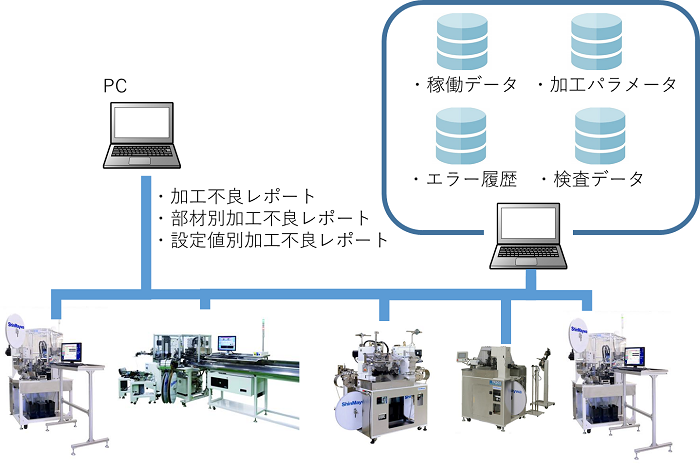

Prior to this system, our company commercialized a simplified remote monitoring system in 2019. The simplified version utilizes status outputs from automatic wire processors, such as signal indicator lights, to aggregate information on a single PC for each factory or line. By storing information in the data center, users can remotely check the operating status of equipment in real time via a web server. This has enabled us to provide a variety of on-site support, including early recognition of equipment abnormalities, real-time performance confirmation of each equipment, and creation of daily, weekly, and monthly reports based on stored information.

However, when a machining defect occurs, tracing the cause often depends on the experience of the operator, resulting in problems such as "it takes time to identify the cause'' and "the cause cannot be identified.''

The highly functional version of this system aims to overcome the problems of the simple version, and uses a dedicated analysis tool to investigate the causes of stoppages, such as machining defects, that occur during operation, based on more detailed operational status record data. We have even automated the presentation of results. By identifying the cause of machining defects at an early stage, it contributes to improving equipment operating rates.

In order to contribute to improving the productivity of our customers, our company will continue to pursue productivity through the development of new technologies and improved quality, and will continue to enhance after-sales services.

1. Features of the high-performance remote monitoring system (model: RMA01)

The following three reports are automatically created based on the information stored in the PC of automatic wire processors

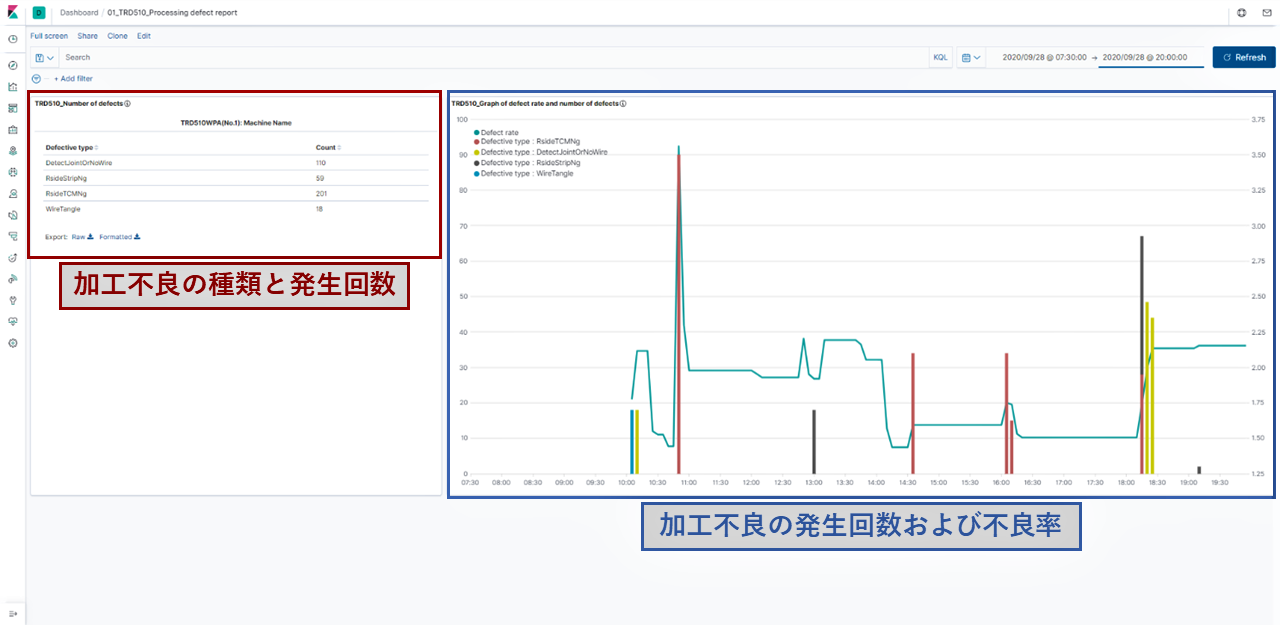

- 1"Types of machining defects and number of occurrences" per hour

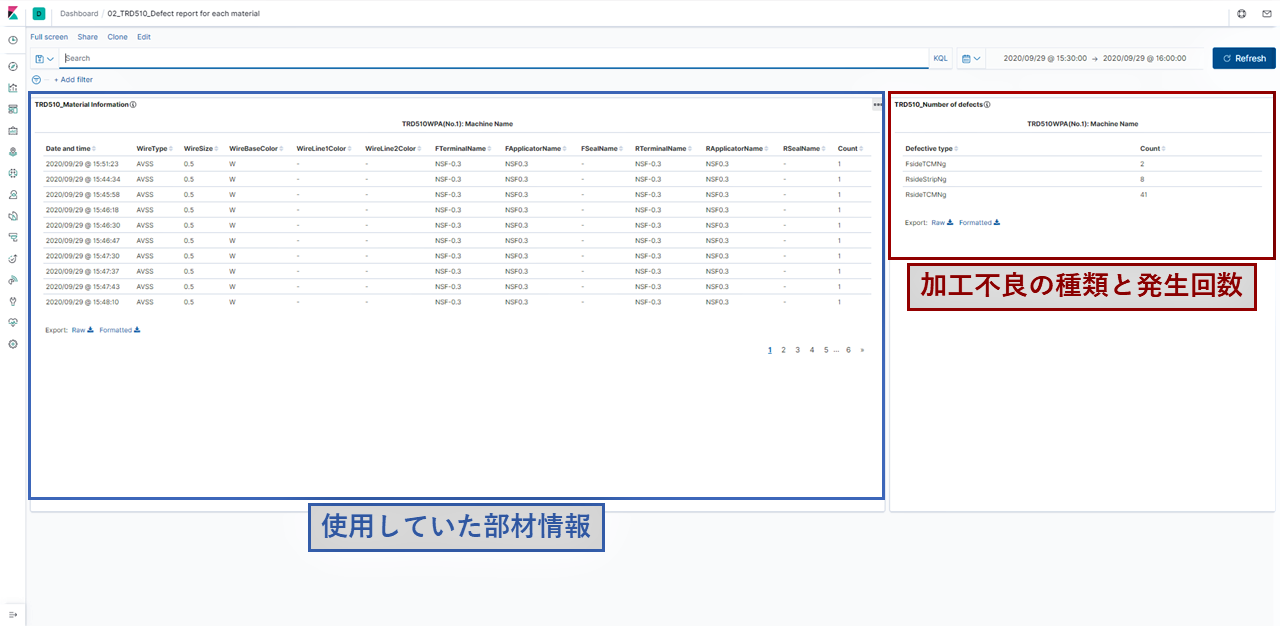

- 2 Relationship between “types of machining defects and number of occurrences” and “information on parts used”

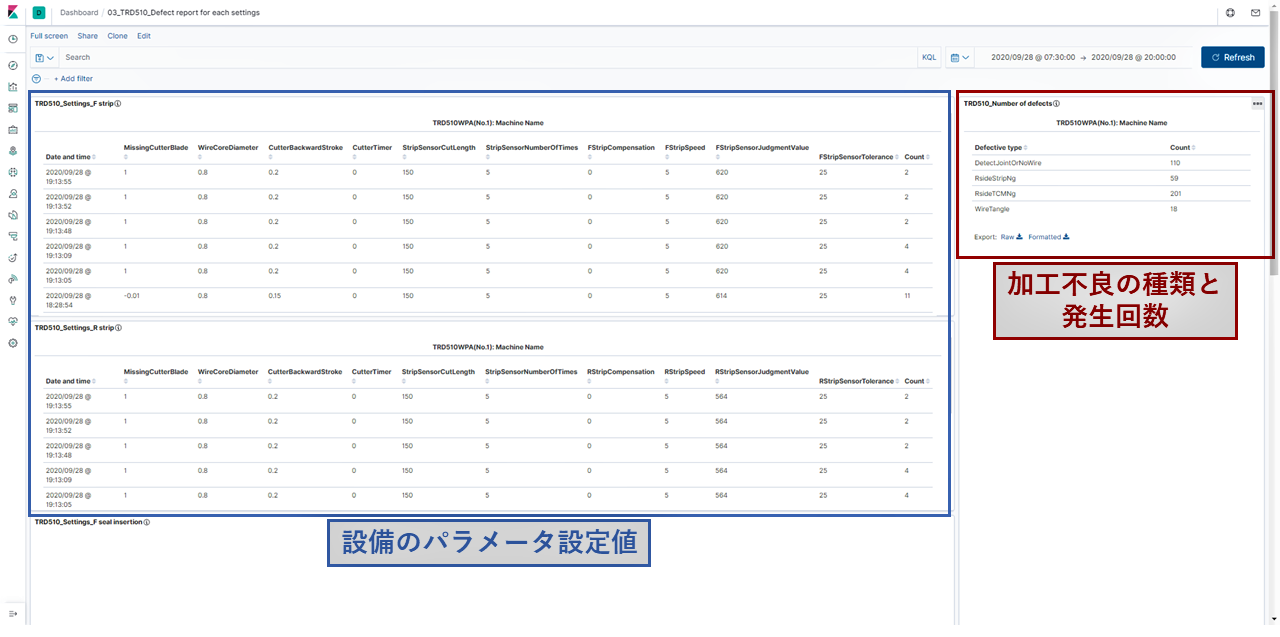

- 3 Relationship between “types of machining defects and number of occurrences” and “equipment parameter settings”

2. Sales start date

November 2020

3. Target model

TRD510 series machine

- * PC-operated models will be released in due course.

4. Sales plan

In FY2020, 2 customers/period. 20 customers/period in 2 years.

5. Selling price

Installation kit fee: ¥120,000 (first unit), ¥72,000 (second and subsequent units).

(Does not include data center PC. Local construction costs are separate)

License fee: Select either ¥5,000/unit/month or ¥50,000/unit/year

Contact Information

About products

Sales Department

Wire Processing System Department, Industrial Machinery Systems Division, ShinMaywa Industries, Ltd.

Address:

3-2-43 Shitte, Tsurumi-ku, Yokohama, Kanagawa, 230-0003, Japan

For news organizations

ShinMaywa Industries, Ltd. Public Relations/IR Department Corporate Planning Headquarters

1-1 Shinmeiwa-cho, Takarazuka, Hyogo, 665-8550, Japan

The information published in this content is current as of the date of publication.

Please note that this information may differ from the latest information due to changes in our group's business strategies and organization.