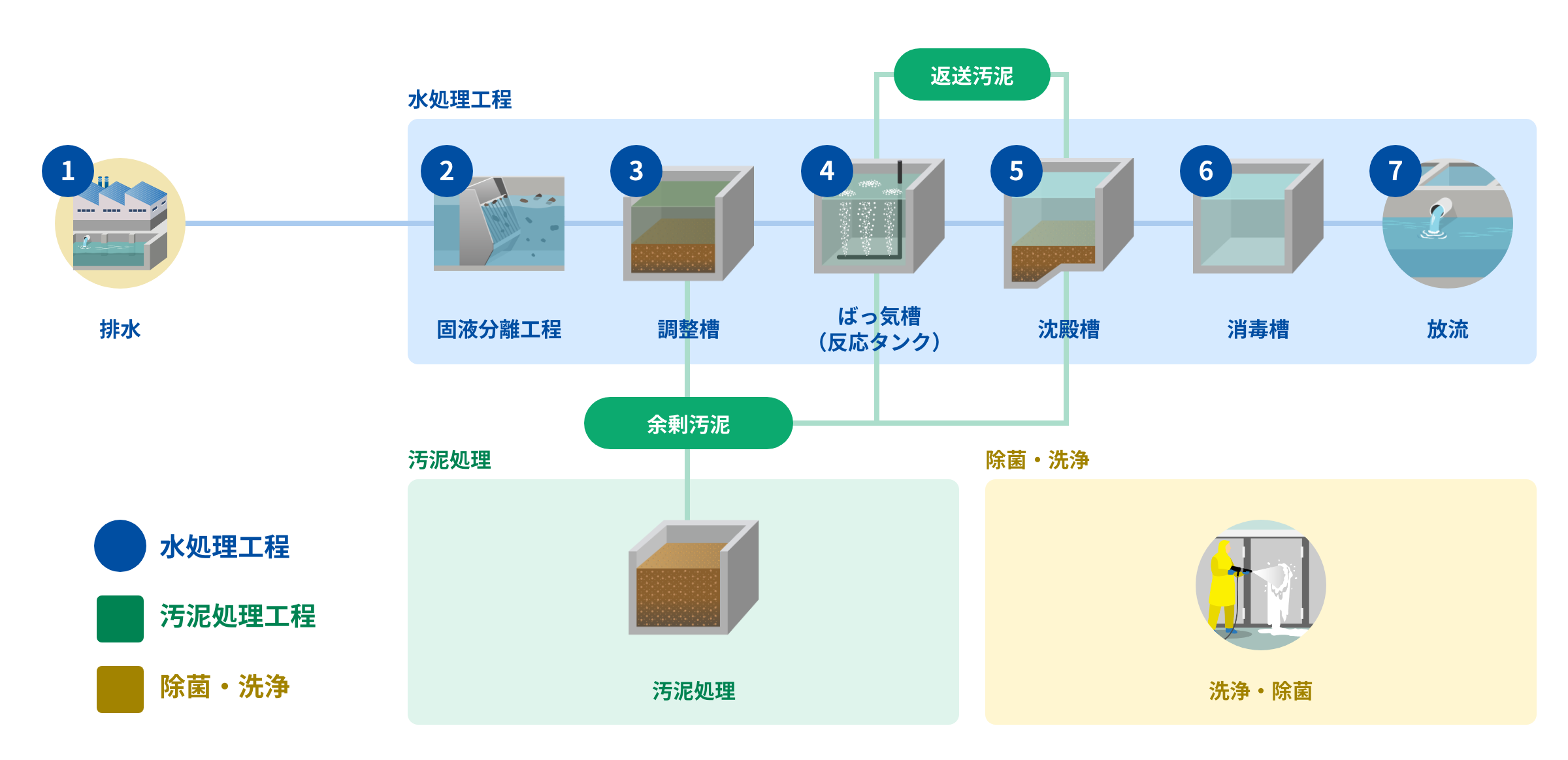

Factory wastewater and sludge treatment, disinfection, and cleaning Factories

Back

treatment

1Industrial wastewater

Wastewater drainage from factories

Wastewater drains from factories and other business sites.

2Separation of liquids and solids

The first process of industrial wastewater treatment

In the grit tank, wastewater first passes through screens to remove any large debris.

-

SB (SS screen,

SB (SS screen,

built-in rotary

brush unit) -

SS screen S

SS screen S

-

Wedge wire

Wedge wire

drum screen

DSA series

3Regulating tank

Reducing the burden on downstream processes

Water volume and quality are regulated for greater uniformity.

process

4Aeration tank (Reactor tank)

Purification by bacteria

Bacteria in the water feed on contaminants, cleaning the water.

Air is mixed into the water so that bacteria have enough oxygen to do their work.

-

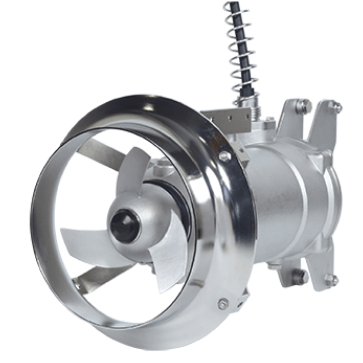

Submersible Mixers

Submersible Mixers

SM/SME -

Submersible

Submersible

Aerator -

Vertical

Vertical

low-power mixer

SVM -

Roots blower

Roots blower

ARH -

Roots blower

Roots blower

ARS -

Turbo blower

Turbo blower

STX series

5Settling tank

Just the clean water is taken out

Bacteria that have eaten contaminants slowly settle out, forming activated sludge; some of this sludge is returned to the reactor tank.

6Disinfection tank

Final process of wastewater treatment

With the disinfection of the water taken out, its treatment is complete.

7Discharge

Part of a clean water cycle

The treated, clean water is discharged into streams or the ocean.

Eventually, it will form clouds and fall back to land as rain.

Sludge treatment

Disposal of residual sludge

Sludge is stored, thickened, and dehydrated, then disposed of as industrial waste.

Disinfection and cleaning

High-pressure hot water cleaning, low-pressure hot water disinfecting

This product efficiently cleans and disinfects food factories that require strict hygiene control and chemical plants that use toxic substances.

Please contact our sales department for further details.

Inquiry form