ShinMaywa Develops New Automatic Wire Terminating Machine Model for Both-ends Crimping

November 06, 2019

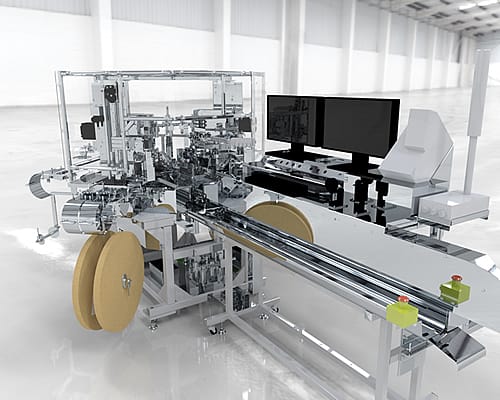

ShinMaywa Industries, Ltd. automatic wire processors (Head Office: Takarazuka, Hyogo, Japan, President: Isogawa Tatsuyuki) has developed a new product Both-ends crimping machine "TRD701", which measures and cuts wires used in wire harnesses (assembled wires) and processes terminals such as crimping, and will be exhibited at the exhibition "Productronica 2019" to be held in Munich, Germany, from November 12 to 15, 2019. We will be exhibiting at productronica 2019.

In recent years, in the automobile market, technological development has been accelerating in response to CASE (connected, autonomous driving, sharing, and electrification). Vehicles are increasingly equipped with a large number of electronic precision devices, including circuit-based control equipment as standard equipment, and the amount of wire harnesses used per vehicle is increasing, leading to an increase in total demand for wire harnesses worldwide.

Against this background, automatic wire processors are required to further improve productivity and meet high processing quality requirements.

The newly developed "TRD701" Both-ends crimping machine is based on the concepts of High Performance (improved processing capacity), Better Quality (improved processing quality), and Less downtime (improved productivity by shortening setup time). We have significantly improved the throughput and quality of wire processing, and also shortened setup time.

In terms of processing capacity, by reducing the weight of the rotating unit and optimizing the platform to shorten takt time, we have achieved a maximum processing capacity of 4,300 pieces per hour (approx. 30% increase compared to our previous machine) when both ends are crimped at 1,000 mm. Did.

Regarding processing quality, we have improved quality reliability by installing various new sensors such as a high-precision terminal crimping monitor (HTCM), core contact detection (CTD), and image strip sensor (SVS). In terms of productivity, the use of a two-wire automatic exchange device, servo-controlled wire drawing machine, two-stage sorting tray, double cutter head, nozzle-less wire clamp, etc. reduces setup time and contributes to improved productivity. .

We will continue to pursue productivity through the development of new technologies and quality improvements, as well as the enhancement of after-sales services, in order to contribute to improving the productivity of our customers.

1. Features of the new Both-ends crimping machine “TRD701”

(1) High Performance (improved processing capacity)

Achieves high throughput by shortening takt time by reducing the weight of the rotating unit, etc.

-

Max. processing capacity

Both ends crimped at 1,000 mm 4,300 pieces/hour (approx. 30% increase compared to our previous model)

[Both ends crimped at 100mm 5,200 pieces/hour (approx. 37% increase compared to our previous model)]

(2) Better Quality (new sensor that improves processing quality)

- High Precision Terminal Crimping Monitor (HTCM)

Detects 10% or more of core wire breaks and separates even minute defects, with high judgment performance in terminal crimping

- Core contact detection (CTD)

Detects contact between stripping blade and core wire to prevent core wire breakage

- Image strip sensor (SVS)

Detect stripping, seal insertion, and semi-strip defects during processing operations using wire and seal silhouettes

(3) Less downtime (shorten setup time with various new functions)

- 2 wire automatic switching device

The next lot of wires can be set during processing, greatly reducing wire replacement time (standard manual time 40 seconds → 15 seconds)

- Servo-Controlled Wire Straightener

A servo motor controls the wire drawing machine that corrects wire curls, greatly reducing setup time.

- 2-tier sorting tray

While sorting good/defective wires, only good wires are discharged to the lower wire holder, minimizing machine down time due to wire removal, improving setup efficiency.

- Double cutter head

Equipped with two types of stripping blades on the cutter head, compatible with different wire types and sizes without changing blades.

- Nozzle-less wire clamp

Eliminates the need to replace nozzles to match the wire size, greatly reducing setup time

2. Scheduled to start selling

April 2020

3. Price

12 million yen (CE marking compatible specifications/excluding tax)

4. Main sales target

Wire harness manufacturers

5. Sales targets

FY2020: 100 units

6. Specifications (standard specifications)

| Model | Both-ends crimping machine TRD701 |

|---|---|

| Max. processing capacity | Both ends crimped 4,300 pieces/hour at 1,000 mm (5,200 pieces/hour at 100 mm) |

| Applicable wire range | 0.13~6.0 mm2 |

| Length measurement ability speed | 12 m/s |

| Press capacity | 24.5 kN (equivalent to 2.5 ton) |

7. “Productronica 2019” Exhibition Information

Our company will be exhibiting at the exhibition "Productronica 2019" to be held in Munich, Germany from November 12th to 15th, 2019. In addition to the recently developed new Both-ends crimping machine "TRD701," we also plan to demonstrate the following wire processing machines and peripheral equipment.

| Exhibition name | Productronica 2019 |

|---|---|

| Meeting period | November 12-15, 2019 |

| Venue | Messe Munchen (Munchen, Germany) |

| Our booth number | Hall A5, Stand 360 |

| Our exhibited products |

|

Contact Information

About products

Sales Department

Wire Processing System Department, Industrial Machinery Systems Division, ShinMaywa Industries, Ltd.

Address:

3-2-43 Shitte, Tsurumi-ku, Yokohama, Kanagawa, 230-0003, Japan

For news organizations

ShinMaywa Industries, Ltd. Public Relations/IR Department Corporate Planning Headquarters

1-1 Shinmeiwa-cho, Takarazuka, Hyogo, 665-8550, Japan

The information published in this content is current as of the date of publication.

Please note that this information may differ from the latest information due to changes in our group's business strategies and organization.