Environmental Protection Activities

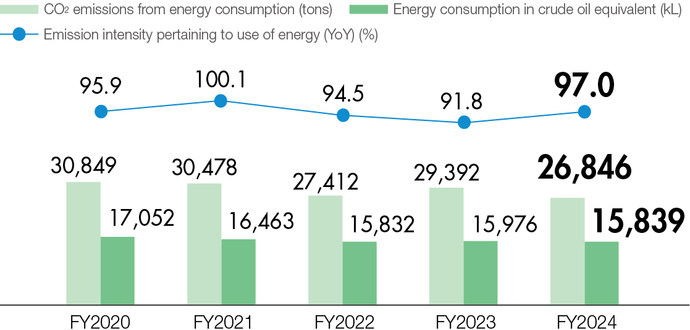

The Group continuously monitors CO2 emissions, energy consumption, and other factors as it works to facilitate the reduction of its environmental burden.

Measures to reduce the environmental burden and combat climate change

Since the 1980s, we have been working for many years to prevent

global warming by making effective use of fossil fuels (natural

resources) mainly at our plants.

In 2012, the Company was designated as a specified business

operator under the revised Act on Rationalizing Energy Use, and

we have been engaged in Company-wide efforts to further

conserve energy.

In addition, from FY2022, we have set a new goal of

reducing total CO2 emissions by 38%*1 by FY2030,

and we are implementing measures aimed at

achieving this goal.

- *1 Compared to our peak value recorded in FY2017.

Activities in FY2024

In FY2024, we installed solar power generation panels on the roof

of new “large-scale submersible pump operation inspection

equipment” that we constructed at the Ono Plant, a production

base for fluid products. Electric power obtained through the panels

was utilized to contribute to the reduction of CO2 emissions (52

t-CO2/year). We have also worked to develop a company-wide

system concerning the introduction of solar power generation

equipment and procurement of CO2-free electric power as

environmental investments.

In addition, we have put a system in place to manage the

CO2 emissions of major Group companies in Japan and overseas

and measure Scopes 1 and 2 emissions on a consolidated basis.

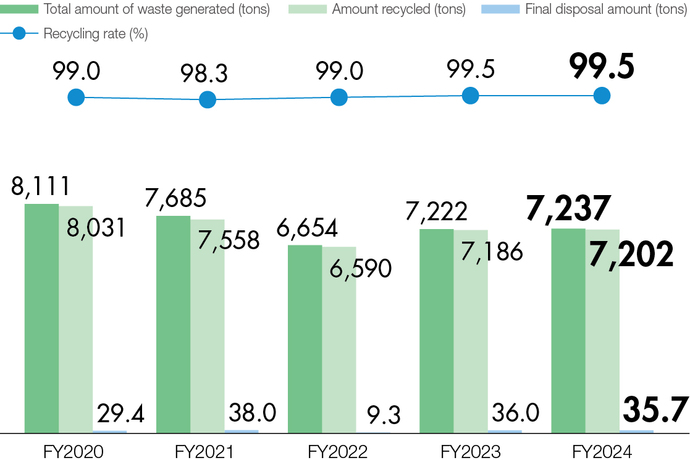

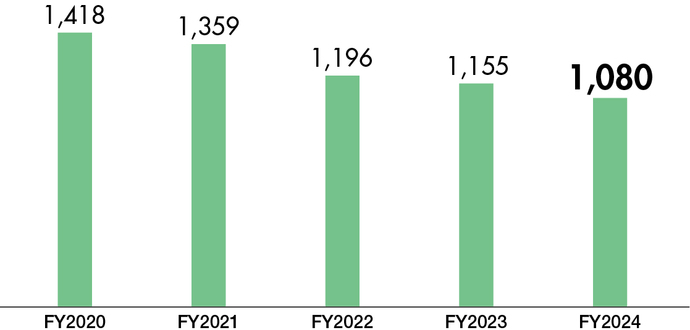

Waste reduction

The Company is committed to reducing waste and recycling through the 3Rs (Reduce, Reuse, Recycle) as well as Refuse (not accepting things that will end up as garbage). In our efforts to realize a recycling-based society, we have also set new targets in FY2022 of reducing total waste emissions by 10% *2 by FY2030 and achieving a recycling rate*3 of 99% or more.

- *2 Compared to FY2020

- *3Recycling rate: Amount of waste recycled/ Total amount of waste generated × 100 (%)

Activities in FY2024

We have been engaged in efforts to minimize the amounts of input materials and waste in line with a further improved yield in manufacturing and facilitate the conversion of waste to resources with value by thorough separation and sorting.

プラスチック廃棄物排出量の削減

当社は、事業活動に伴って発生するプラスチック廃棄物の排出量について、売上高原単位で2021年度比9.0%の定常的な削減(2030年度)を目標に掲げ、削減に向けた取り組みを進めています。

2024年度の売上高原単位は、2023年度に比べて増加したものの、依然として低い水準にあります。この低水準には、事業構成の変化といった一時的要因が影響しています。また、これらの要因が順次解消された場合には、売上高原単位は増加に転じると推定されます。

こうした状況を踏まえ、当社は工程の効率化、分別廃棄の徹底、再資源化の推進など、環境負荷低減に向けた取り組みを一層強化し、目標の達成を目指してまいります。

| 2021年度実績 | FY2022 results | FY2023 results | 2024年度実績 | |

|---|---|---|---|---|

| 排出量(t) | 545 | 509 | 540 | 577 |

| 売上高原単位(kg/百万円) | 4.19 | 4.00 | 3.55 | 3.61 |

Cooperating with JICA Knowledge Co-Creation Program “Basics of Solid Waste Management”

In accordance with its Sustainability Management Policy, the Group aims to

contribute to society at large through its business activities. Since FY2011, we

have been cooperating with the Knowledge Co-Creation Program “Basics of

Solid Waste Management,” a training program hosted by the Kansai Center of the

Japan International Cooperation Agency (JICA).

This training program was organized by the Learning and Ecological

Activities Foundation for Children (LEAF), a non-profit organization commissioned

by JICA, for government and municipal officials in the Pacific, Asia, Latin America

and other regions. The objective of the program is to learn about solid waste

management in partnership with private sector and civil society. The curriculum

consists of lectures and on-site tours on such topics as waste treatment in local

governments in Japan, building a recycling-based society, and recycling of

recyclable materials. We took the group to the Hiroshima Plant, and following a

lecture titled “Our Initiatives as a Refuse Compactor Manufacturer” in the morning,

we gave a tour of the production site on the theme of “Training on the Operation

and Repair of Refuse Compactors” in the afternoon to provide the group with

explanations on operation methods and safe handling using actual vehicles. This

training was resumed from FY2023 as it had been suspended from FY2020 to

FY2022 due to the COVID-19, and was attended by participants from the

countries shown below in FY2024.

By continuing to actively cooperate with JICA trainings, we aim to

contribute to solving the world’s waste issues with our refuse compactors.

| Date | Country | Number of trainees |

|---|---|---|

| September 3, 2024 | Cambodia, Ethiopia, Lebanon, Philippines, South Sudan, Sudan, Vanuatu | 7 |

| December 5, 2024 | Bhutan, Bosnia and Herzegovina, Brazil, Kosovo, Republic of Macedonia, Papua New Guinea, Serbia, Republic of Turkey, Uzbekistan | 9 |

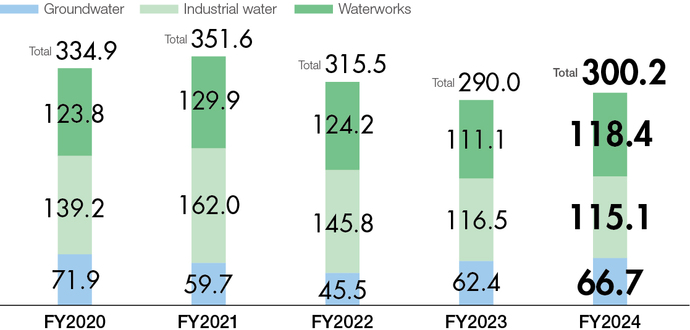

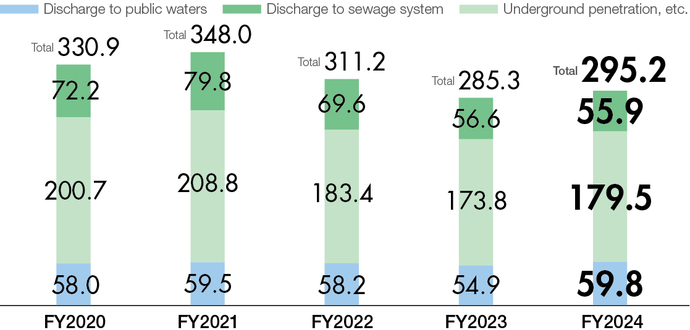

Protecting Water Resources and Reducing Water Use

Saving water, a limited and precious resource, also leads to energy

savings in the water purification process. Our plants are thus committed

to proper management of both its water consumption and wastewater

discharge, and in FY2024, as in the previous years, there was no noncompliance

with laws or ordinances.

Although the Company evaluates that its water risk is low owing to

its limited water consumption, the Company will take climate change and

the local water situation into account and enhance efficiency in the

sustainable use of water resources. The Company will continue monitoring

its water consumption and promote water management that emphasizes

coordination with local communities.

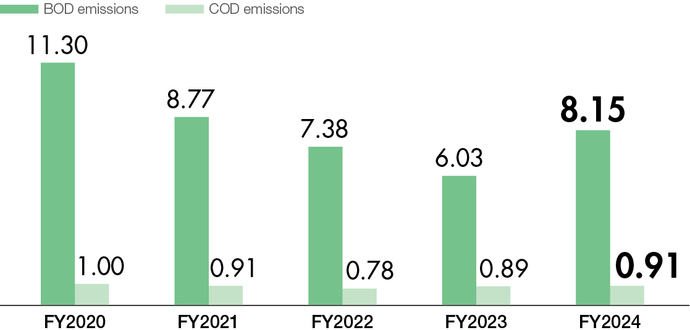

Reducing emissions of pollutants

For substances discharged from our plants into the atmosphere and water, we set voluntary emission limits that are stricter than legal regulations*4 in our efforts to reduce our environmental impact.

- *4(Examples) NOx: Approximately 30–70% of the legal limit; BOD: 50% of the legal limit (Aircraft Division Konan Plant).

Management of chemicals

We continually work on the proper management of chemicals, and in FY2024, as in the previous years, non-compliance with or a violation of laws or ordinances was not confirmed.

The Company’s fluorocarbon emissions were 17.3 t-CO2 in FY2024. We stably mange emissions through the appropriate maintenance and management of refrigerant equipment.

Regarding substances subject to PRTR system, the release and transfer volumes were 116,300 kg and 12,863 kg, respectively, and both volumes were properly managed.

The Company will continue to thoroughly comply with laws and ordinances and strive to further reduce its environmental burden through introducing alternative substances and reviewing manufacturing processes.