Plasma Ion Processing System

Technical Information

What is Plasma Ion Processing System?

Plasma (ion) processing is a surface modification technology using ions generated by plasma.

As application examples, it is used for nitride processing and shape improvement of metal working tools.

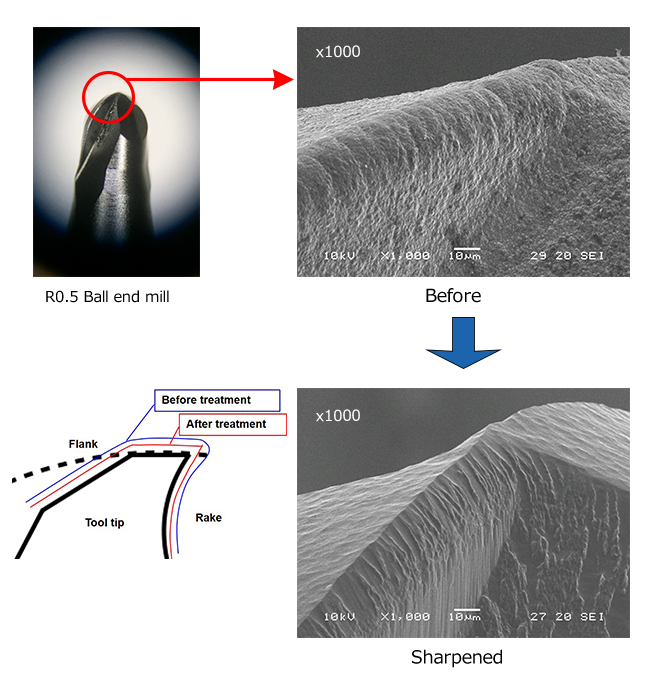

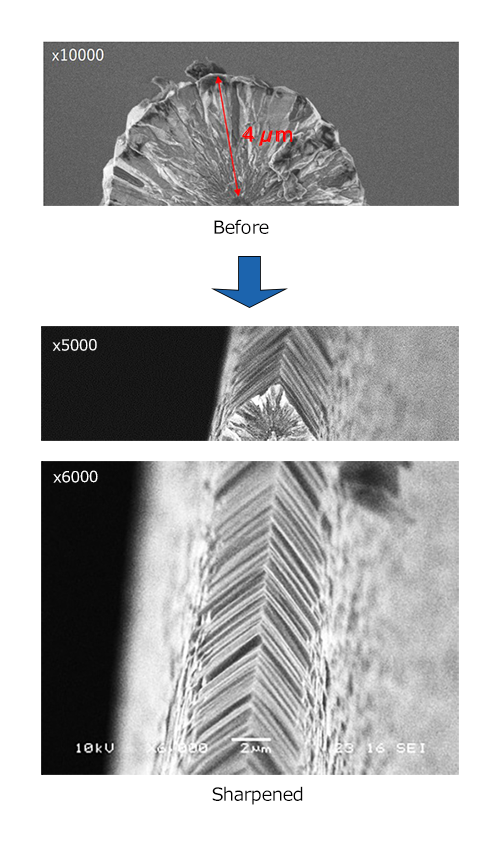

Sharpening of cutting tools by Plasma treatment

Diamond coated cutting tool

Sharpening of Diamond coated tools by unique plasma treatment

Diamond coating achieves the improvement of wear resistance and longevity!

However... the cutting edge is rounded...

Sharpens the coating itself without damaging the base material

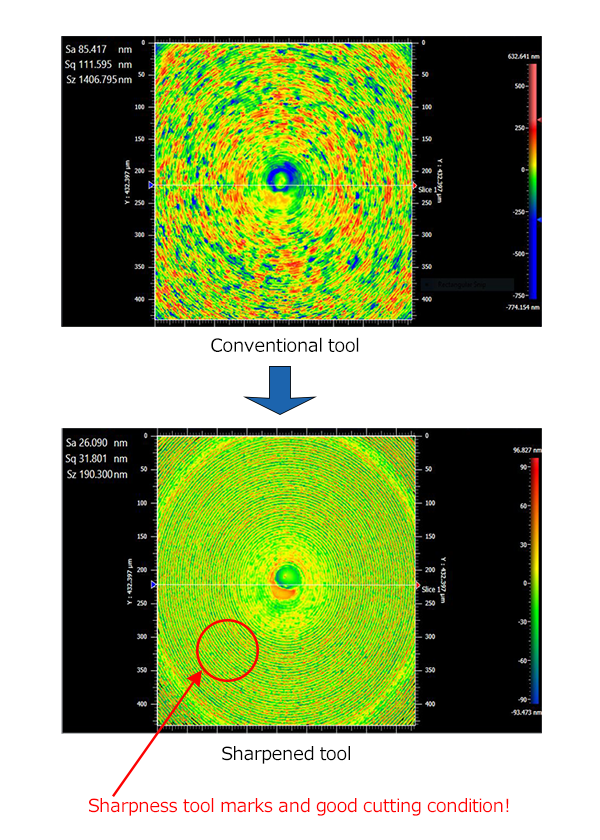

Cutting test with sharpened diamond coated tool

(Right) Machined surface by sharpened tool

| Tool | R0.5 diamond coated ball end mill |

|---|---|

| Work | Ultra-fine grained carbide (lens-shaped processing) |

| Evaluation | Comparison of surface condition of machined surface

|

Diamond coated blade

Plasma Nitriding

Principle of Plasma Nitriding

A hollow cathode type plasma generator creates nitrogen plasma and introduce it into the vacuum chamber.

Nitrogen plasma ions are accelerated by the bias voltage applied to the specimen, bombarding. Nitrogen-based intermetallic compounds are createsd on the surface of the specimen.

Characteristics of Plasma Nitriding

- We use argon gas which has low environmental impact and nitrogen gas. It provides a better work environment. (Ammonia gas is not necessary.)

- Temperature increases up to processing temperature only by plasma power. It is a simple structure.

- Nitride processing can be done on stainless steel.

Advantage

- Improved hardness

- Improved wear resistance

- Improved corrosion resistance

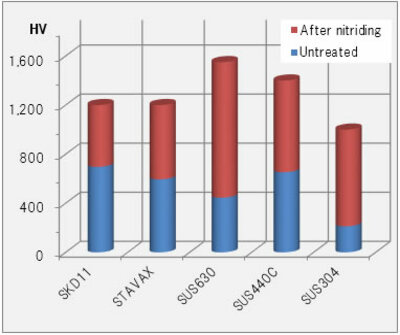

Surface hardness of various materials

| Before treatment (HV) | After treatment (HV) | |

|---|---|---|

| SKD11 | 697 | 1200 |

| STAVAX | 595 | 1200 |

| SUS630 | 446 | 1550 |

| SUS440C | 653 | 1400 |

| SUS304 | 213 | 1000 |

Application examples

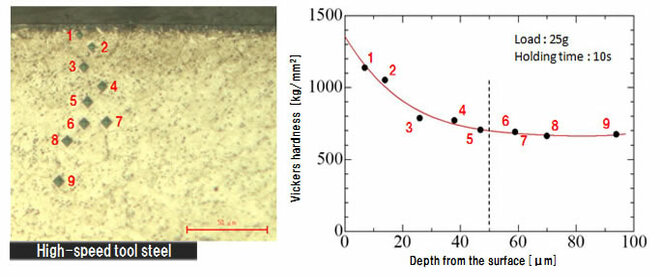

Application to high speed tool steel

A cross-sectional view of high-speed tool steel after nitriding treatment (left) and hardness change from the surface (right) are shown.

Measure several points from the surface to the depth using a Vickers hardness tester.

The surface hardness varies depending on the target material and processing conditions.

System specifications

| Specifications | |

|---|---|

| Size | W 2,200mm |

| D 2,100mm | |

| H 2,650mm | |

| Weight | Approx. 2,600kg |

| Gas | Ar, N2 |

| Temp. | <500℃ |

| Plasma source | 1 unit |

Contact Information

Click here for product inquiries.

Search for other products and services