Diamond Coating System

Technical Information

What is Diamond Coating System?

Diamond is the most stiff material in existing materials, and it is a very excellent substance in mechanical, electrical, chemical and thermal conductivity. Diamond can be provided as a coating, it can be contributed in various fields, so research and development is proceeding.

As a method of synthesizing diamond, high pressure high temperature method(HPHT), hot filament CVD method, and microwave plasma CVD method, etc. are available, and from various excellent characteristics such as improvement of wear resistance of cutting tool and improvement of durability of electrolytic electrode application is expected.

ShinMaywa’s Diamond Coating System

Adopting the hot filament CVD method, diamond can be synthesized on a large area, and it can be applied to mass production products such as coating on cutting tools.

Unique technology optimizes adhesion and also offer conductive diamond coating. We can propose the system sales and also coating service.

In addition, we can propose recycling such as film removal and re-coating by taking advantage of our ion etching technology.

Application

- Cutting tools for CFRP, Graphite and Aluminum processing

- Dies & Molds

- Seal component

- Electrode

- * Please contact us about developing new applications.

System specifications

| System/Method | Hot Filament CVD |

|---|---|

| System Dimension | L 2,480 x W 1,320 x H 2,240 |

| Vacuum chamber size |

L 620 x W 600 x H 500 |

| Applicable substrate size |

Tools:⌀0.5 - ⌀20 L200 |

| Flat Substrate:⌀250 t30 | |

| Substrate material | Carbide, Ceramics, heat-resistant material |

| Coating length | 50mm |

| Power supply | 3 phase 200V 50kVA A type ground connection |

| Coolant | 25L/min |

| Gas | CH4, H2, N2 and available additional port |

| Weight | Approx. 2,000 kg |

- * Due to diamond coating temperature will be around from 800degC to 900degC, substrate material shall be

limited heat-resistant material.

For coating on cobalt content carbide, de-cobalt pretreatment is required.

Also our pretreatment system can be offered as turnkey.

Optimized diamond grain size can be offered for each applications.

We can also propose microwave plasma CVD equipment.

- DIAVAC Limited (our group)

Application examples

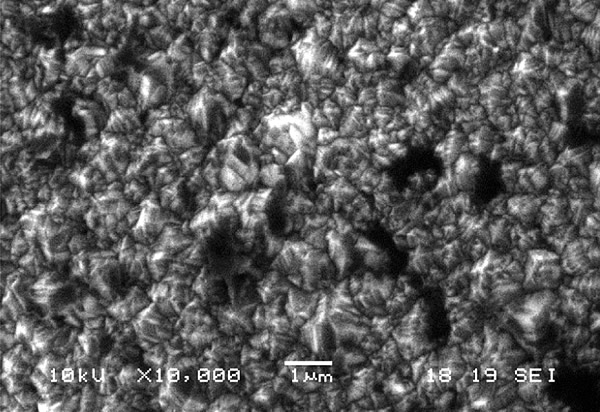

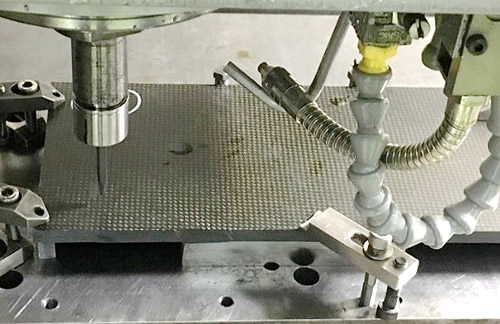

CFRP drilling test of same tool shape and different coating #1

CFRP thickness:8.5mm

Dry processing

Movie

[Playtime: 37 seconds]

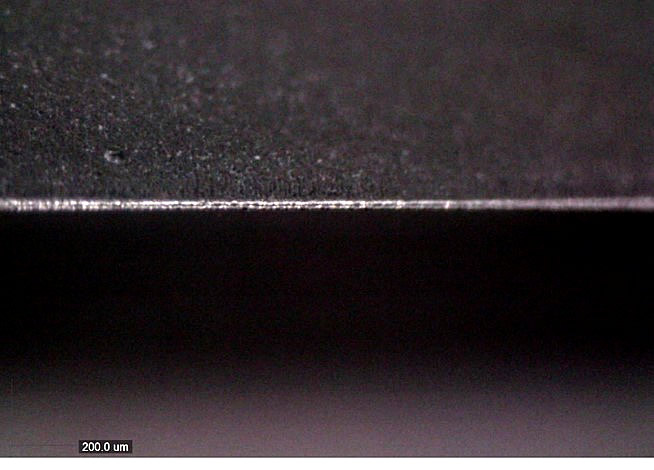

Improvement of wear condition of tool edge after 100 holes

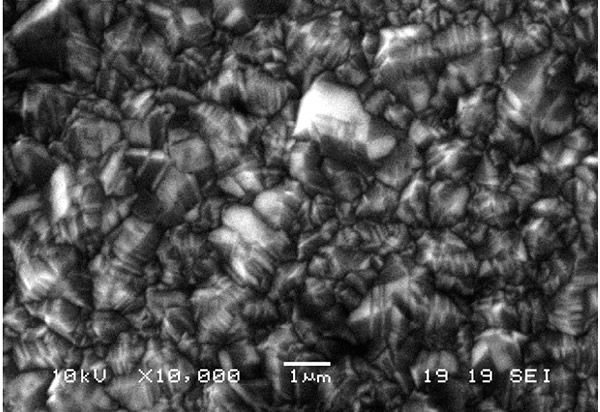

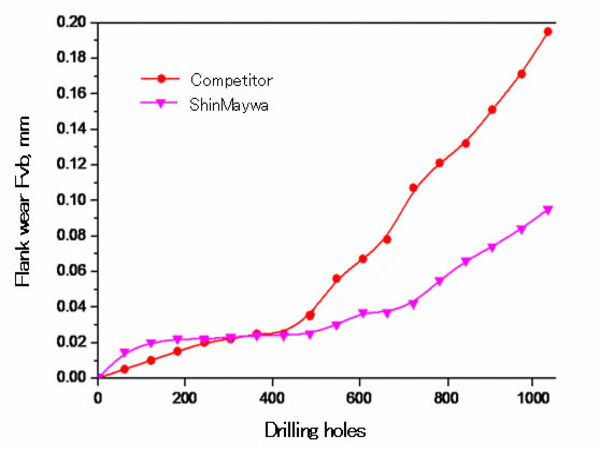

CFRP drilling test of same tool shape and different coating #2

CFRP thickness:8mm

Dry cutting

Reduce wear and extend tool life!

Click here for microwave plasma CVD equipment

- DIAVAC Limited (our group)

- https://www.diavac.co.jp/item1/マイクロ波プラズマcvd装置/

Contact Information

Click here for product inquiries.

Search for other products and services