ShinMaywa INSIGHT

[Product History] Industrial Machinery Systems Division’s Automatic Wire Processors

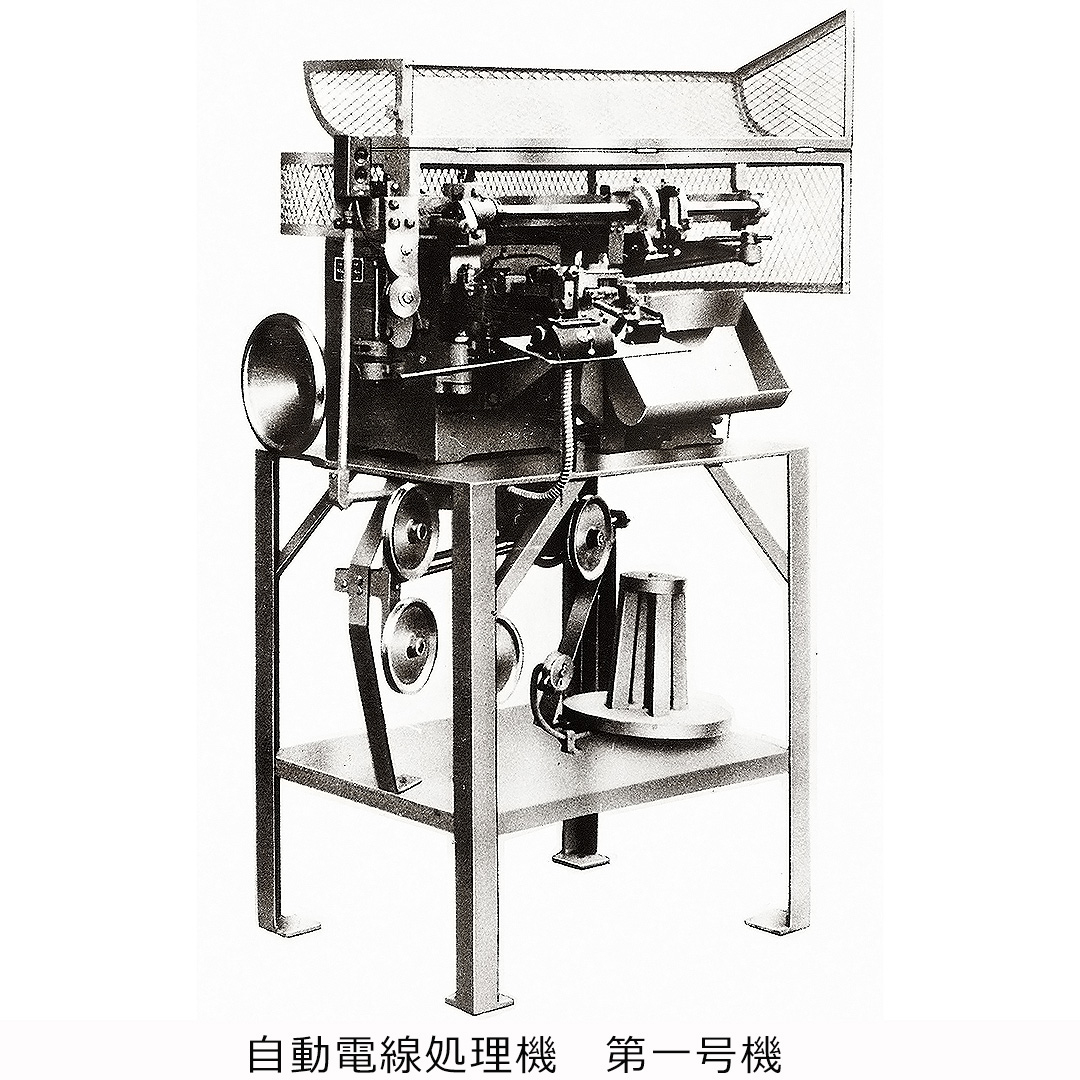

We will now introduce the history of one of the Industrial Machinery Systems Division's primary products, the automatic wire processor. (The picture above is the first automatic wire processor.)

What are automatic wire processors?

Automobiles and electrical appliances are lined with various electric wires, which are called wire harnesses when bundled together to form a component. These are an essential part of automobiles and electrical appliances, comparable to nerves or blood vessels.

Automatic wire processors are devices that automatically perform a number of processes in the wire harness production process, such as cutting wires, stripping wire insulation, and crimping terminals. Our products have a good reputation with our customers for their ability to perform precise machining operations at high speeds.

The Beginning:

Developing the wire stripper, which automatically strips wire insulation

In the 1950s, at the request of a major electrical appliance manufacturer, we developed the “wire stripper,” Japan’s first automatic wire processor.

Afterwards, in response to increased production of home appliances and automobiles, we improved the equipment to automatically perform terminal crimping on wires of a variety of lengths. It eventually grew to become one of the core products of our industrial machinery systems business.

We have been actively expanding overseas since the 1990s, and we boast a high market share in North America and Southeast Asia. At present, besides our production activities in China, we are aiming to enter the European market as well.

Automobiles and electrical appliances are lined with various electric wires, which are called wire harnesses when bundled together to form a component. These are an essential part of automobiles and electrical appliances, comparable to nerves or blood vessels.

Automatic wire processors are devices that automatically perform a number of processes in the wire harness production process, such as cutting wires, stripping wire insulation, and crimping terminals. Our products have a good reputation with our customers for their ability to perform precise machining operations at high speeds.

The Beginning:

Developing the wire stripper, which automatically strips wire insulation

In the 1950s, at the request of a major electrical appliance manufacturer, we developed the “wire stripper,” Japan’s first automatic wire processor.

Afterwards, in response to increased production of home appliances and automobiles, we improved the equipment to automatically perform terminal crimping on wires of a variety of lengths. It eventually grew to become one of the core products of our industrial machinery systems business.

We have been actively expanding overseas since the 1990s, and we boast a high market share in North America and Southeast Asia. At present, besides our production activities in China, we are aiming to enter the European market as well.

Automatic wire processor assembly process (at that time)

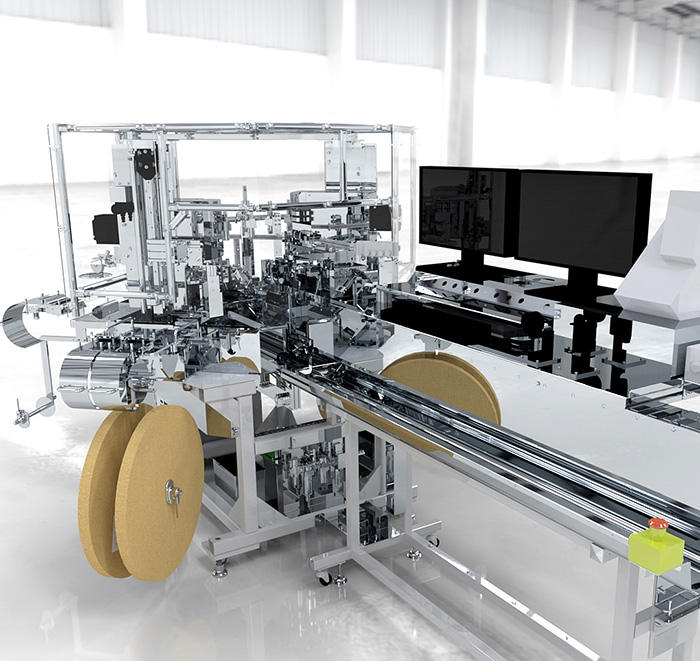

The latest automatic wire terminating machine (TRD701)

The latest automatic wire terminating machine (TRD701)

If you wish to learn more, we have a video that chronicles our history. Please give it a watch!

ShinMaywa’s products and services continue to support social infrastructure throughout society today.

Search by theme

#サステナビリティ

#社会インフラを支えています

#輸送

#3つの領域

#パーキングシステム

#都市

#環境

#保守

#研究開発

#新規事業

#流体

#川西機械製作所

#川西航空機

#新明和グループ

#AI

#水素

#US-2

#アップサイクル

#機械式駐車設備

#航空機

#特装車

#採用

#産機システム

#DDモータ

#環境システム

#自動電線処理機

#民間航空機事業

#航空旅客搭乗橋

#真空装置

#テールゲートリフタ

#ダンプトラック

#ごみ中継施設

#脱着ボデートラック

#アームロール®

#水中ミキサ

#リサイクルセンター

#水中ポンプ

#塵芥車

#飛行艇

#XU-M

#XU-L

#佐野工場

#US-1A改

#製品紹介

#エレパーク®

#ループパーク®

#パックスウェイ®

#US-1

#UF-XS

#PS-1

#甲南工場

#XU-S

#キャリア

#世界で活躍中

#US-2ができるまで

#マンガ暮らしを支える新明和

#真空成膜のお話

#歴史

#イベント

#お知らせ