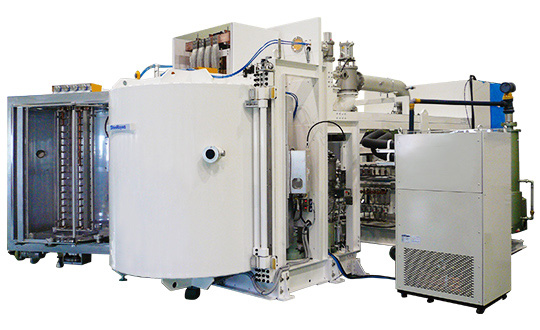

Batch type vapor deposition + plasma polymerization system

Features

- Two vertical doors provide high productivity

- Direct evaporation on plastic substrate and protective film coating by parallel electrode for plasma generation produce high quality deposition

- Advanced current control device minimizes aluminum splash during evaporation

- Electric driving is available for door open and close to lessen the operator' s workload(option)

Specifications

| Model | VCD1000AD | VCD1300AD | VCD1450AD | VCD1800AD |

|---|---|---|---|---|

| Substrate size (Including jigs, etc.) |

φ350×1,200mm 4 axes φ320×1,200mm 5 axes |

φ400×1,200mm 6 axes φ450×1,200mm 5 axes |

φ450×1,500mm 6 axes φ500×1,500mm 5 axes φ550×1,500mm 4 axes |

φ450×1,500mm 8 axes φ550×1,500mm 6 axes |

| Model | VRD650AD | VRD750AD | ||

|---|---|---|---|---|

| Substrate size (Including jigs, etc.) |

φ540×1,500mm 2 axes | φ600×1,500mm 1 axis |

Main use

- Formation of reflective and protective films for automobile lamp reflectors and other automobile interior and exterior parts

- Formation of reflective films for cosmetic containers, mirror parts, etc.

Contact Information

Click here for product inquiries.

Search for other products and services

ShinMaywa INSIGHT

March 09, 2022