Supply Records

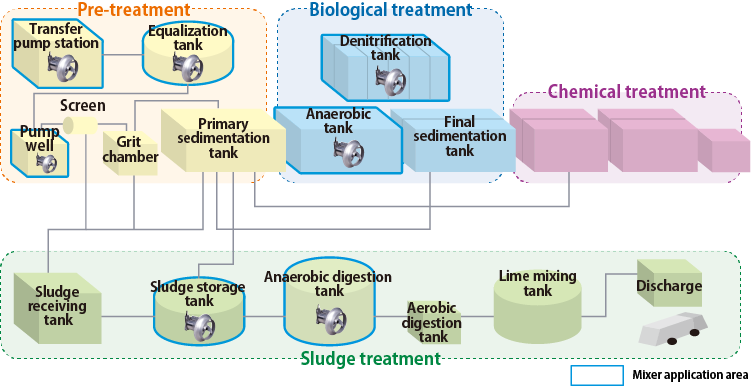

Example of Submersible Mixer Application

at Wastewater Treatment Plant

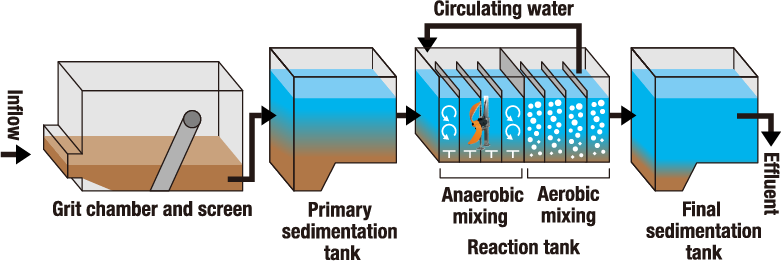

Advanced Wastewater Treatment Method

Conventionally, purification is performed by mixing activated sludge while supplying oxygen. However, the conventional method has the disadvantage of insufficient removal of nitrogen and phosphorus. To overcome this disadvantage, anaerobic mixing, in which no oxygen is supplied, and aerobic mixing, in which oxygen is supplied, combine to maximize the capability of various bacteria, as an advanced wastewater treatment method.

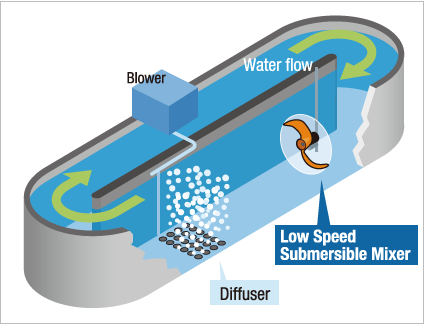

OD (Oxidation Ditch) Method

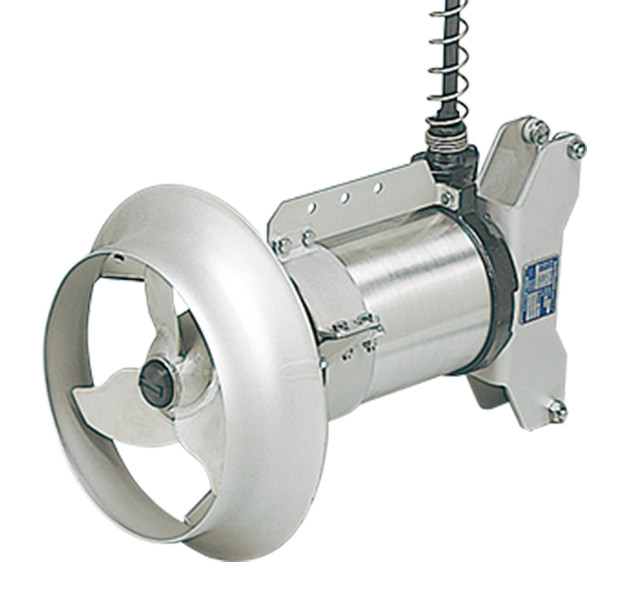

The oxidation ditch method performs aeration while circulating activated sludge in a circulating channel. The repeated starting and stopping of the diffuser enables anaerobic and aerobic mixing, just like an advanced wastewater treatment method. ShinMaywa low speed submersible mixer can be used for this system.

Energy savings achieved by replacing from the blower

Customer's problem

The water level in the equalization tank was raised due to the increased amount of drainage water, which sometimes resulted in blower overload. At the same time, pH adjustment was also performed in this tank, but the adjustment occasionally failed, which precluded the stable operation of the treatment facility.

Proposal from ShinMaywa

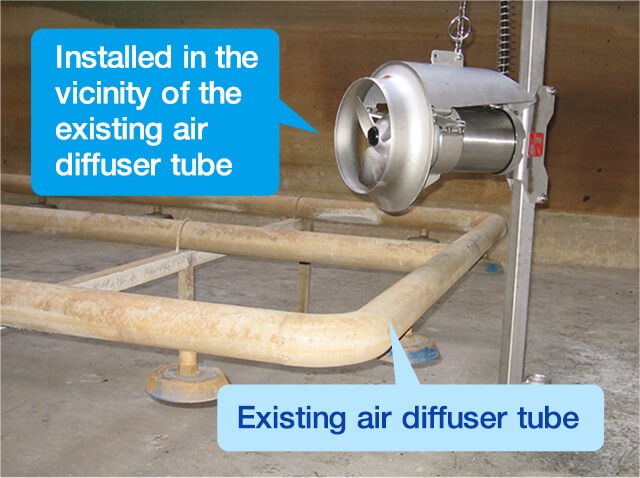

We recommended to use submersible mixers instead of diffuser system, because its driving power is unaffected by changes in the water level and it can significantly reduce the output.

Effect

Various problems have been solved and energy savings have been achieved at the same time.

| Before replacing | |

|---|---|

| Product in use | Blower |

| Rated output | 15.0kW |

| Number of units | 1 |

| Replacing to be used | |

|---|---|

| Product in use | Submersible mixer |

| Rated output | 1.5kW |

| Number of units | 2 |

Uniform mixing in a tank achieved with creative thinking

Customer's problem

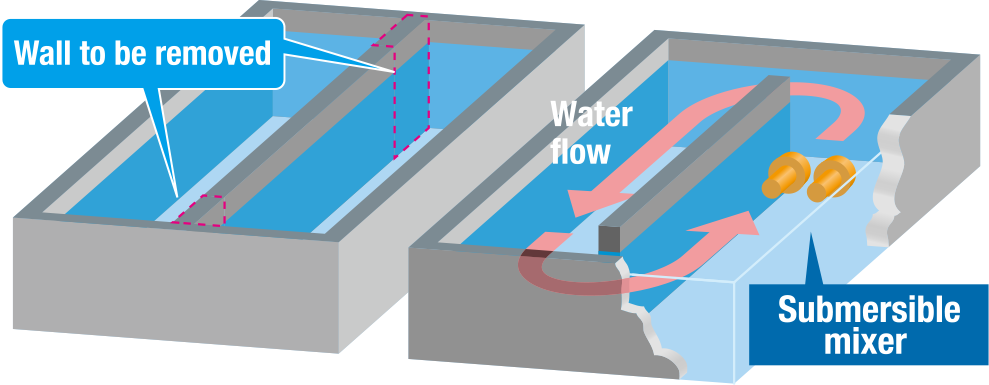

Mixing by air alone resulted in uneven water quality due to the elongated shape of the sewage water tank. This unevenness resulted in instability in the quantity of chemical agent added in the next process, which adversely affected treatment quality.

Proposal from ShinMaywa

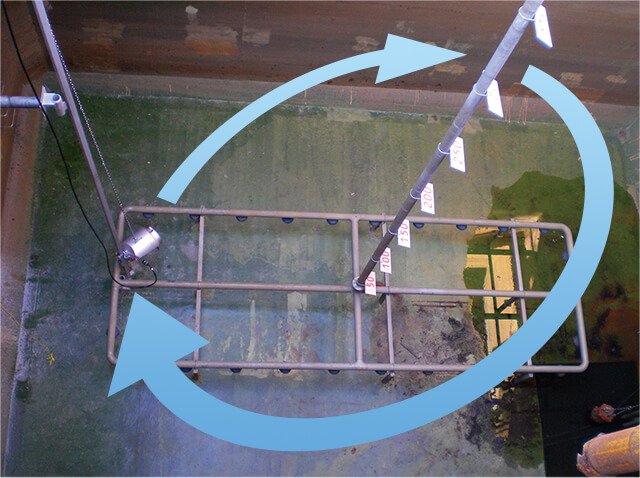

We recommended that part of the wall between the two adjacent tanks be removed to change the shape of the water tank into that a looped style, and the installation of submersible mixers to create a large circulating flow.

Effect

This has almost eliminated changes in the quantity of chemical agent added in the next process, thereby stabilizing the water quality. Furthermore, this reduces the quantity of the chemical agent required.

| Mixers to be used | |

|---|---|

| Model | SM15JA |

| Rated output | 1.5kW |

| Number of units | 2 |

| Purpose | Uniform mixing in the tank |