Energy Saving Proposal by Replacing Roots Blowers

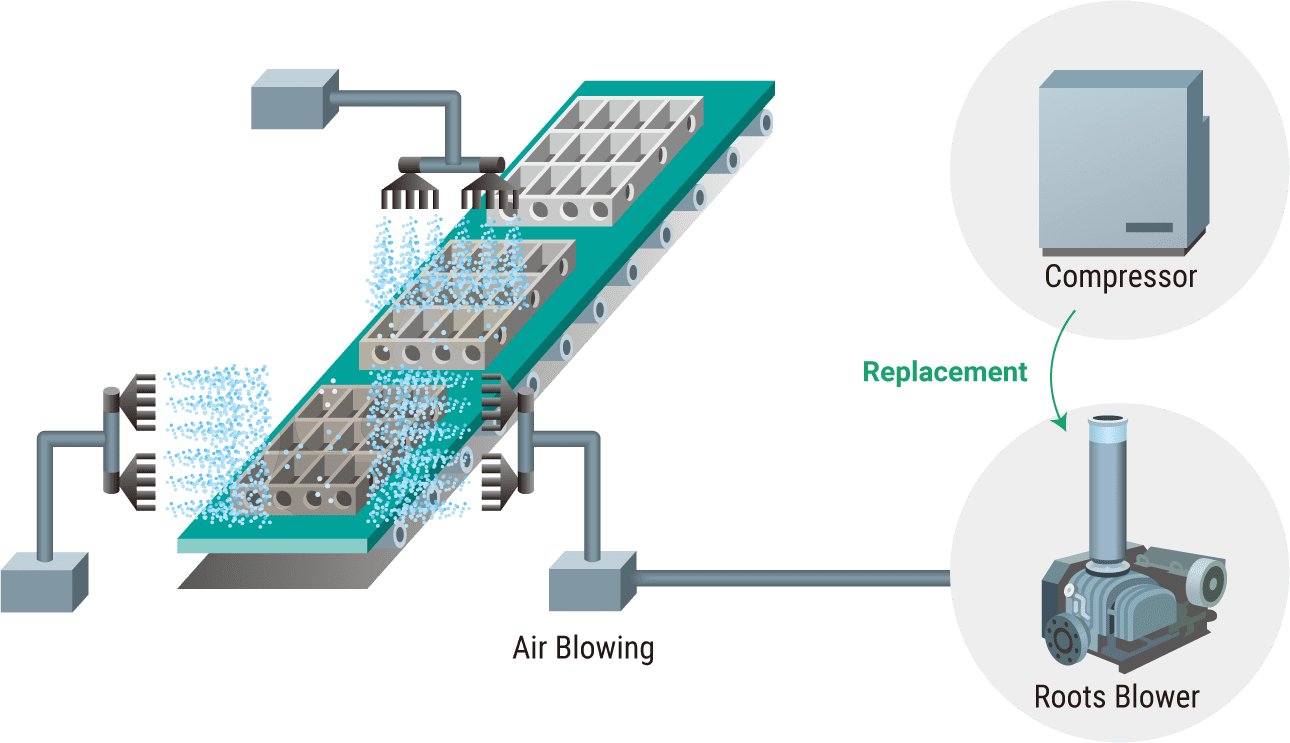

Replacing to a Roots Bower can greatly reduce air consumption by the compressor during air blowing processes (water removal, drying, dust removal).

* You can expand the figure below with your fingers.

Replacing a compressor with a Roots Blower for air blowing

Compressors vs. Roots Blowers for blow-off

| Compressor | Roots Blower | |

|---|---|---|

| Blow distance | 100mm | 100mm |

| Pressure just before nozzle | 250kPa | 22kPa |

| Internal diameter of nozzle | φ3 | φ9.5 |

| Air speed on work surface | 102m/s | 102m/s |

| Airflow | 2.67m3/min | 7.18m3/min |

| Shaft power | 15.3kW | 5.9kW |

| Annual electricity charge | 367,200yen | 141,600yen |

1. The air blowing speed on the work surface is a value calculated by ShinMaywa that has been corrected using an empirical formula.

2. The air blowing speed on the work surface was adjusted to at least 100 m/s.

Comparative Example of Pressure just before nozzle

When the air blowing speed on the work surface is set to at least 100 m/s, the compressor requires a pressure just before nozzle of 250 kPa, while the Roots Blower needs only 22 kPa.

The large volume of air in the medium pressure range ensures that the surface windspeed of the workpiece maintains low pressure.

This indicates that switching to a Roots Blower can reduce pressure and save energy.

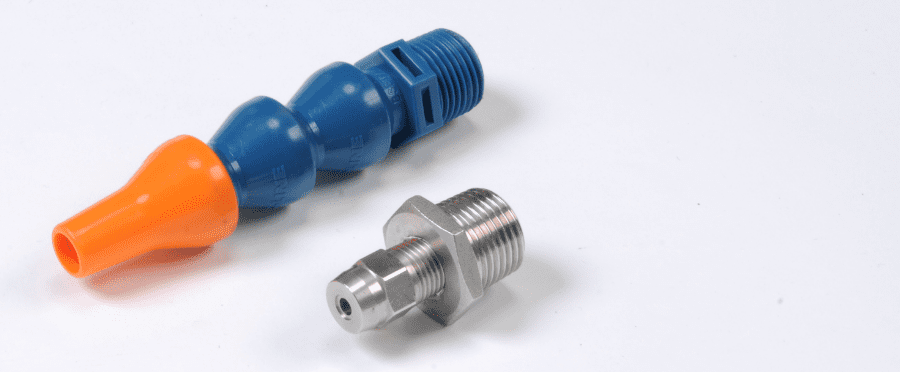

Nozzle for Roots Blower

Nozzle for Roots Blower(φ9.5) Nozzle for compressor

(φ3)

Comparative Example of Annual Energy Savings

Using a Roots Blower for blow-off can deliver outstanding energy savings, reducing annual electricity costs by 225,600 yen (compared to a compressor).

Annual running costs can be reduced by approximately 60%.

Comparison of Electricity Charge

Electricity Charge 60% SAVING Compressor

367,200yen

Roots Blower

141,600yen

Compressor

367,200yen

Roots Blower

141,600yen

Please contact our sales department for further details on Roots Blowers.