Variations

SM-W/SME-W Series

Coating the 316 stainless steel casting propeller by spraying the tungsten carbide. While having excellent corrosion resistance of stainless steel, it greatly enhances abrasion resistance.

Propeller wear is less than half that of stainless steel casting.

"Tungsten carbide spraying" of the propeller's vane part is adopted. The Vickers hardness of tungsten carbide is more than 5 times that of stainless steel, and wear resistance is greatly improved.

Applications

Livestock manure treatment

Uniform agitation of livestock manure

- *For use in other applications (such as factory drainage) , please contact us.

Comparison of propeller wear Operation with No. 5 silica sand 8% mixture

|

|

|

|---|---|---|

| Model | SM | SME-W |

| Accumulated operation time | 46 hours | 90 hours |

| Propeller diameter change (mm) | 254 → 200 | 254 → 254 |

| Propeller weight change | -9% | -5% |

| Change of the thrust | -23% | -15% |

| Material of propeller | 316L stainless steel | 316 stainless steel casting with tungsten carbide splaying |

Tungsten carbide has a Vickers hardness of at least 5 times that of stainless steel and is a stable material. It resists corrosion and exhibits stable characteristics even under harsh environments.

SME-R Series

Suppresses odor generation at a low water level

The installation of an air intake pipe facilitates the air supply.

Applications

Mixing of the pump station for wastewater collection system

Load reduction in post-process (sewage treatment plant) and prevention of hydrogen sulfide generation

Mixing of temporary wastewater storage tank for public and commercial facilities

Preventing sludge deposit and scum generation

Feature

No blower is required as self-aspirating type Supplying oxygen simultaneously with mixing

Submersible mixer is used as a base for supplying oxygen and simultaneously mixing.

Anaerobic mixing is also available

Throttling or stopping air also enables anaerobic mixing.

Prevent clogging

Use of sweepback blade propeller prevents foreign object clogging.

SMM Series

Energy consumption can be reduced to 1 / 2 to 1 / 3 from SM series

high speed submersible mixer, when using in the reaction tank.

Applications

Energy save mixing in denitrification tank and reaction tank.

Features

Energy saving

Mixing of the reaction tank is realized with a slight power density of 2 to 4 W / m3.

Energy consumption can be reduced to 1 / 2 to 1 / 3 compared to SM series high speed submersible mixers.

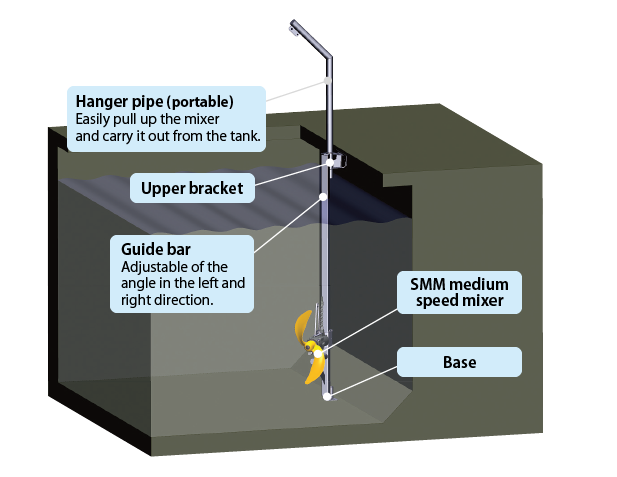

High maintainability

The maintenance cycle is twice as long as the SM series high speed submersible mixer. In addition, it can be easily pulled up with the portable hanger pipe, reducing maintenance costs.

Smooth mixing of biological flocs

A smooth propeller shape and low blade tip speed provide gentle mixing for biological flocs and so on.

Installation on the tank wall side

Unlike other mechanical mixing systems, there is no need for structures (installation structures or inspection walkways) at the center of the tank, so the installation to the existing tank can be reduced the construction period and cost.

Energy save mixing

(Compare in the 11m x 6m x 6m (water height) reaction tank)

Compare with same number of SM series high speed submersible mixer

Compare with same power SM series high speed submersible mixers

Compare with same number of SJL series submersible aerator

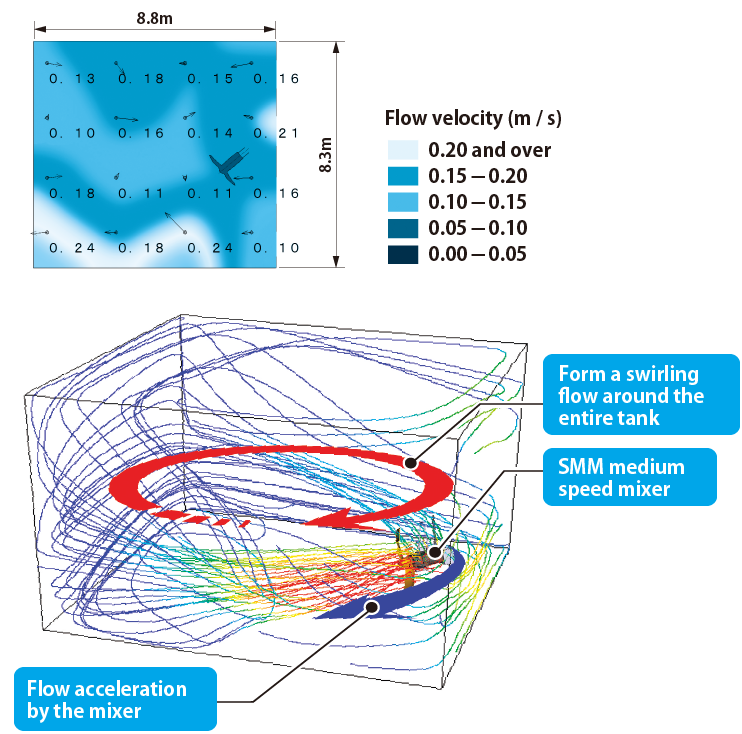

Flow velocity measurement at the bottom of reaction tank

(Tank capacity: 430m3 Power consumption: 630W)

Bottom velocity of 0.1 m / s achieved with a power density of 1.5 W / m3

The strong water flow of the medium speed mixer gradually accelerates the sewage in the tank to create a swirling flow , achieving agitation of the reaction tank with a small power density.

Distribution of biological floc particle size in reaction tank

The particle size distribution of the biological floc is equal to air diffuser system

SML Series

Generate a huge water flow using minimal energy.

Applications

- Generating circulating water flow for Oxidation Ditch (OD) tank

- Generation or circulation of water flow for dam and lake/bog

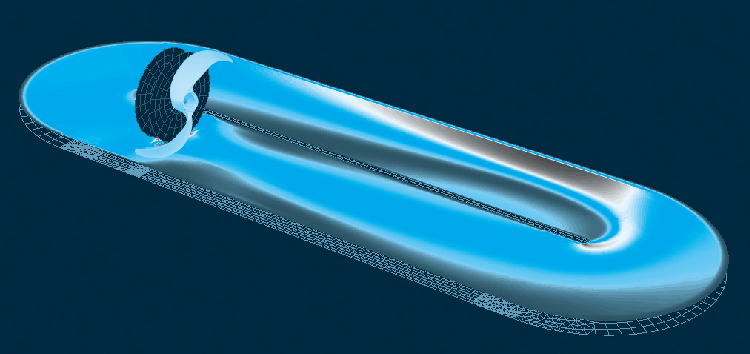

Computational fluid dynamics of oxidation-ditch tank

Features

Strong water flow

Using CFD / CAE analysis, adopt the high-performance propeller that enables both mixing performance and strength. In addition, a structure with a sweepback angle will prevent foreign matters from tangling and provide superb durability.

Safety design

Leakage water chamber is standard on all models to prevent water penetration to the motor. In addition, a leakage detector (optional) prevents insulation deterioration due to leakage water. In addition, adopt the cable with fiber reinforcement, core wire seal shut the water penetrating into the motor.

High maintainability

Under a hanging up condition, oil change for mechanical seal and reduction gear parts, and inspection of the immersion to the leakage water chamber are possible.

Superb reliability

Employs double mechanical seal with silicon carbide (SiC) seal faces that is proven for submersible pumps. Secured the reliability that can withstand the long-time continuous operation required for the submersible mixer. In addition, the propeller shaft is made of corrosion resistant 316 stainless steel. It exhibits reliability in a wide range of environments.

Long service life

Adopt the multi-pole motor with slow rotating speed reduces the load on the reduction gear, which realizes long service life.

Wider scope of application

The high-temperature resistant motor, which reduces temperature rise, is employed to endure liquid temperature up to 40˚C.

Liquid contact part is fully made of stainless steel for applications in wider environment such as seawater.

Propeller Selection Table (propeller cord)

| SML15 |

| SML15 (clear water) / 22 |

| SML22 |

| SML22 (clear water) / 37 |

| SML37 |

| SML37 (clear water) |

| Thrust (N) |

Propeller outer diameter (m) | ||||

|---|---|---|---|---|---|

| 1.4 | 1.6 | 1.8 | 2.2 | 2.5 | |

| 700 | 1023 | ||||

| 800 | 1022 | 1122 | |||

| 850 | 1021 | ||||

| 900 | *1020 / 2024 | 1021 | 1223 | ||

| 1,000 | 2023 | 1120 | 1222 | ||

| 1,100 | 2021 | 2123 | 1221 | ||

| 1,200 | *2020 / 3024 | 2121 | *1220 / 2223 | ||

| 1,300 | 3023 | 2122 | 2222 | 1322 | |

| 1,400 | 3022 | *2120 / 3125 | 2221 | 1321 | |

| 1,500 | 3021 | 3124 | *2220 / 3225 | *1320 / 2324 | |

| 1,600 | 3020 | 3123 | 3224 | 2323 | |

| 1,700 | 3122 | 3223 | 1421 | ||

| 1,800 | 3121 | 3222 | 2322 | *1420 / 2424 | |

| 1,900 | *3120 | 2321 | 2423 | ||

| 2,000 | 3221 | 2422 | |||

| 2,100 | *3220 | *2320 | 2421 | ||

| 2,300 | 3324 | *2420 | |||

| 2,600 | 3323 | ||||

| 2,700 | 3322 | 3423 | |||

| 2,900 | 3422 | ||||

| 3,000 | 3321 | 3421 | |||

| 3,200 | *3320 | *3420 | |||

- To select the size of submersible mixer, calculate necessary thrust for your application and select the size which has greater thrust than calculated one. The required thrust varies depending on the shape and size of tank, and the water quality in each application, so there must have some know-how (experience and expertise) to make correct calculation of required thrust. Please contact to ShinMaywa for correct size selection. Propeller code marked with * cannot be used in the liquid that contains a large amount of foreign object or large specific gravity (1.03 or higher) .