SM/SME Series

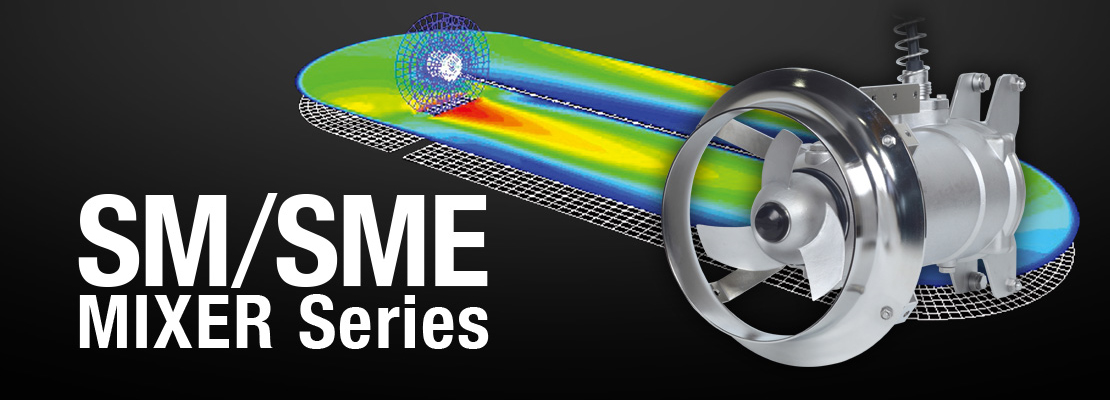

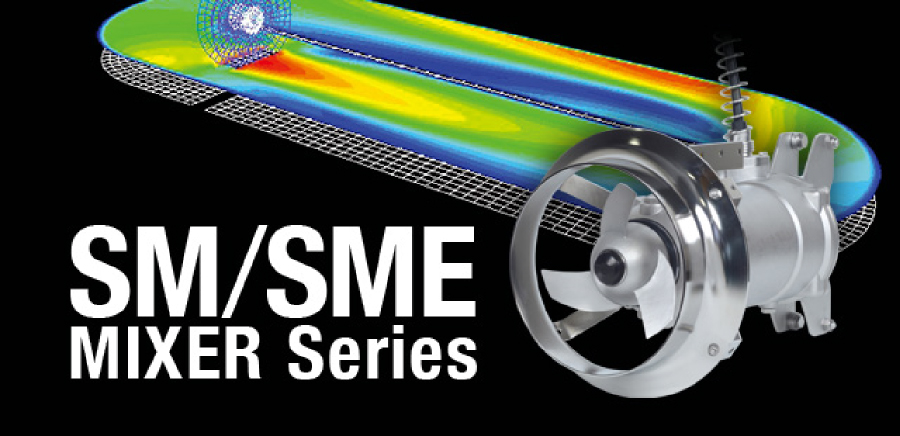

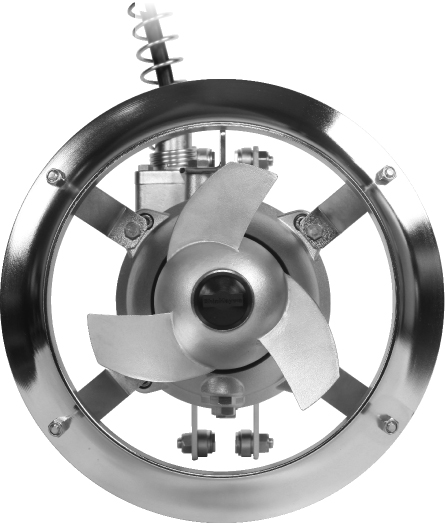

High Speed Submersible Mixer SM/SME Series

- Mixing in a pump well, sludge storage tank or equalization tank

- Crushing scum

Variations

Details

ShinMaywa submersible mixers are robust.

We focus on the smallest details.

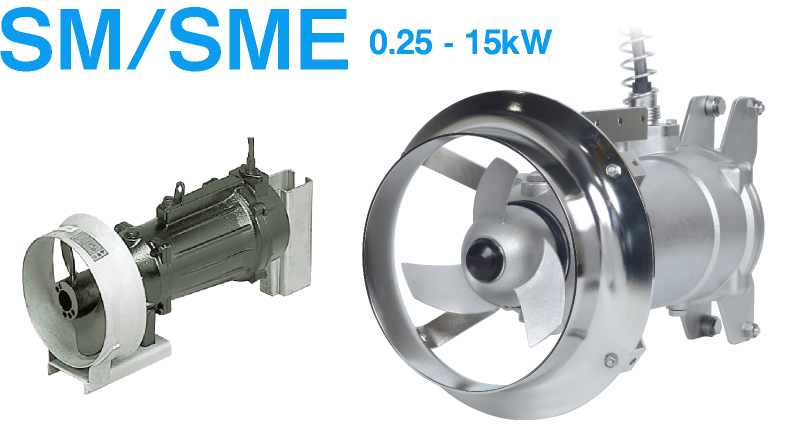

SME Series

Newly developed propeller and motor realize to reduce power consumption

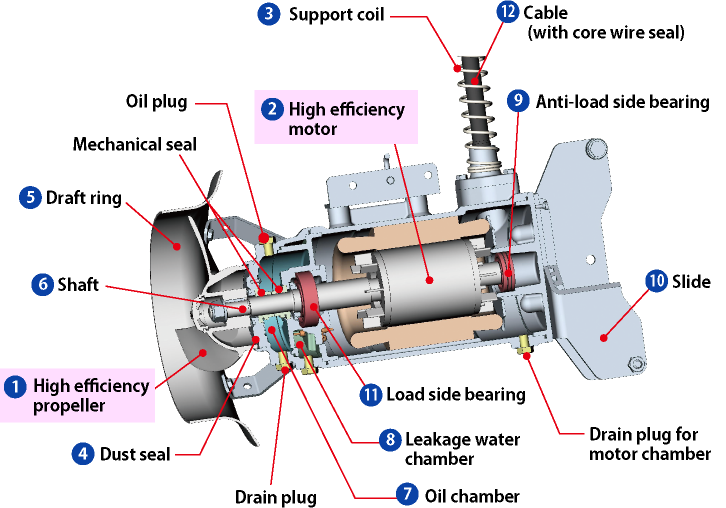

1. High efficiency propeller

Adopt 3-D wing propeller

- Up to 40% reduction in power consumption compared with conventional models.

- Optimum design of propeller using CAE/CFD.

- Achieving the high performance airfoil.

- Improving wear resistance.

- Large thrust propeller for clear water can be used for wastewater.

2. High efficiency motor

Optimum design of winding specifications and silicon steel sheet realize energy saving

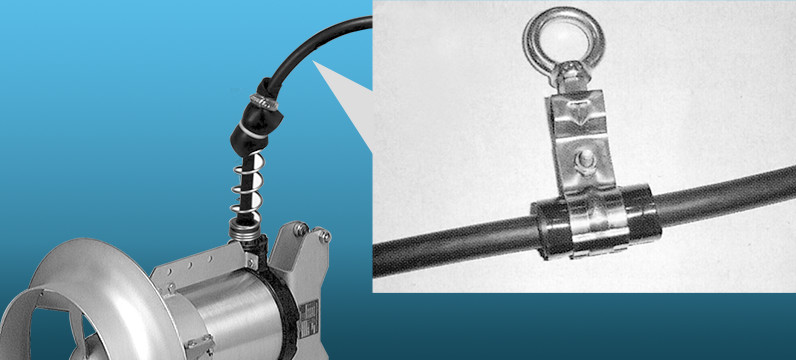

- 3. Support coil

- To fix cable vertically and prevent cable tangling.

- 4. Dust seal

- Double rubber seals prevent penetration and tangling of foreign matters.

- 5. Draft ring

- Assist generating more efficient flow.

- 6. Shaft

- High durability with 316 stainless steel and shorten overhang.

- 7. Oil chamber

Providing an oil plug on the upper surface and a drain plug on the lower surface, oil change can be taken without changing the posture of the mixer.

- 8. Leakage

water chamber - Leakage detector can be equipped (option) . Possible to inspect through inspection plug for leakage water chamber.

- 9. Anti-load side bearing

- Adopt the anti-creep bearing.

- 10. Slide

- Suitable for square pipe of installation equipment and no limitation of installation depth.

- 11. Load side bearing

- Adopt large size bearing which has durability under harsh environment such as sludge, etc.

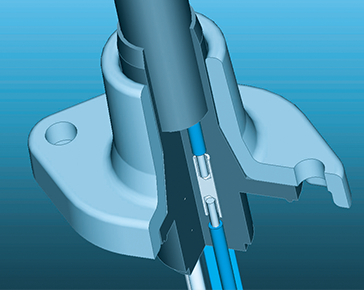

- 12. Cable (with core wire seal)

- Adopt the cable with fiber reinforcement, core wire seal shut the water penetrating into the motor.

- Cable fixture

- Allows you to adjust the cable length and fix the cable in the upper part of a tank to prevent sagging.

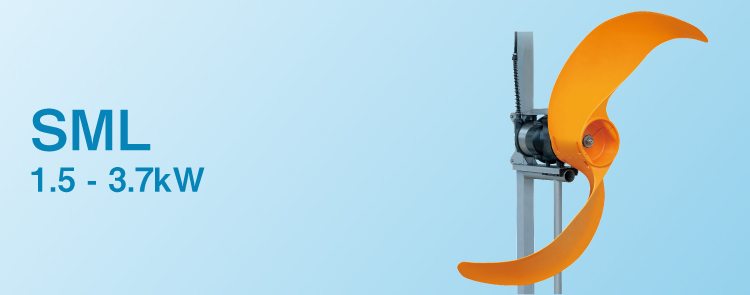

Features

SM/SME Series

- 0.9kW - 7.5kW (50Hz)

- 1.1kW - 7.5kW (60Hz)

Improved reliability

- To prevent cable entanglement, support coil and cable fixture are equipped.

- Adopt the cable with fiber reinforcement, core wire seal shut the water penetrating into the motor.

- Equipped with a leakage water chamber as standard, it protect the bearing and motor from leaked water and oil.

- Employing a large shaft with shorter overhang prevents shaft deflection and mechanical seal reliability is greatly improved.

Superb durability

- Employs double mechanical seal with silicon carbide (SiC) seal faces that is proven for submersible pumps.

- Employed large size bearing for load side, and anti-creep bearing for rear side.

- Propeller has special hardening treatment to improve wear resistance.

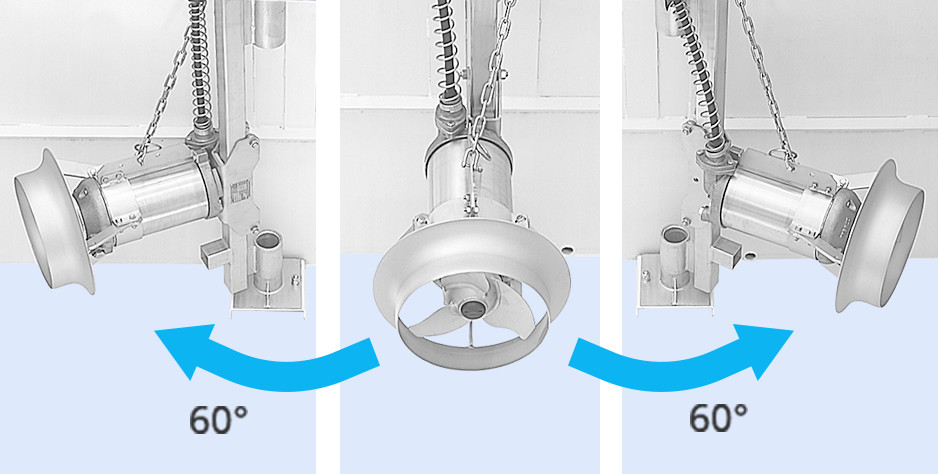

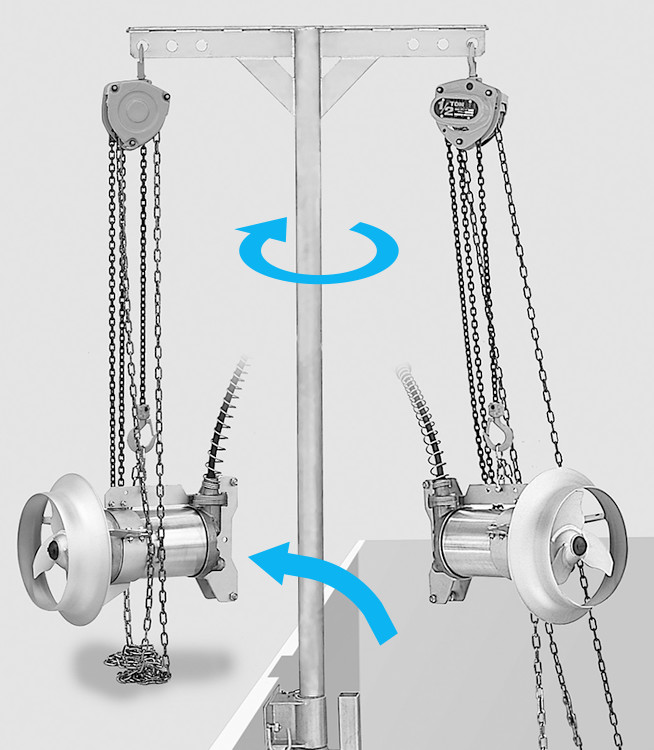

Efficient mixing by simple adjustment

- As position and angle (left / right and up / down) can be easily adjusted to the most efficient location, efficient mixing can be realized in accordance with shape, size and depth of tank, liquid characters and mixing purpose.

Applicable Conditions

| Liquid type | Various types of wastewater and sludge |

|---|---|

| Specific gravity | 1.1 or less |

| Viscosity | 1,000mPa•s or less |

| Temperature | 0°C - 40°C |

| Chlorine ion | 1,000mg/ℓ or less |

| Sludge concentration | 5% or less |

| Water depth | 10m or less |

| pH | 6-9 |

- Applicable liquid specific gravity and viscosity vary per product model.

- Some liquid type may be supported a range exceeding the above scope.

Please contact us.

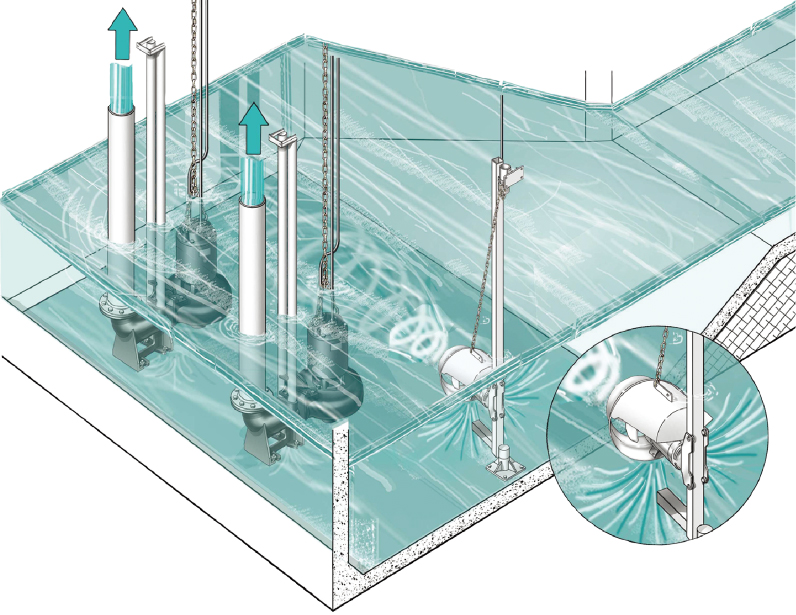

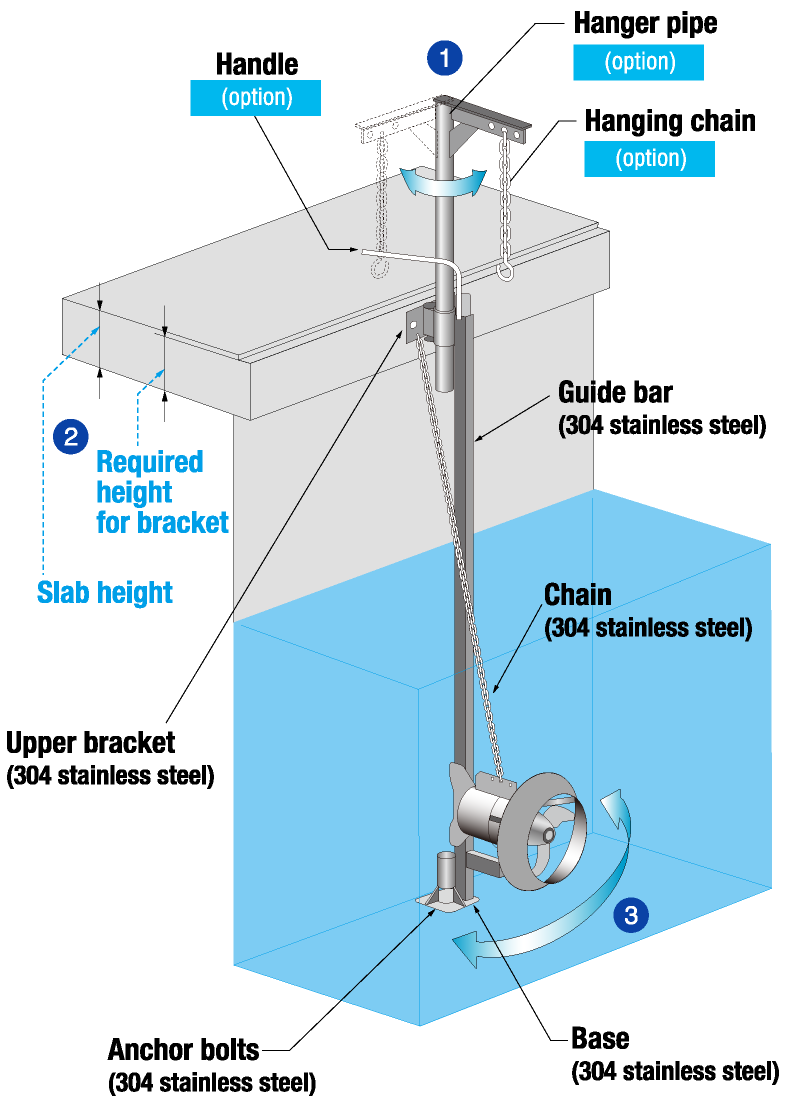

Installation Equipment

Simple adjustment for effective mixing.

1.Easy Pull-out of Mixer from the Tank

Using hanger pipe (option) , lifted mixer can easily rotate to floor side and make easy inspection and adjustment.

2.Required Slab Height

| Guide Bar | Required height for bracket | Slab height (reference) |

| 50 pipe | 150mm | 200mm |

| 100 pipe | 200mm | 250mm |

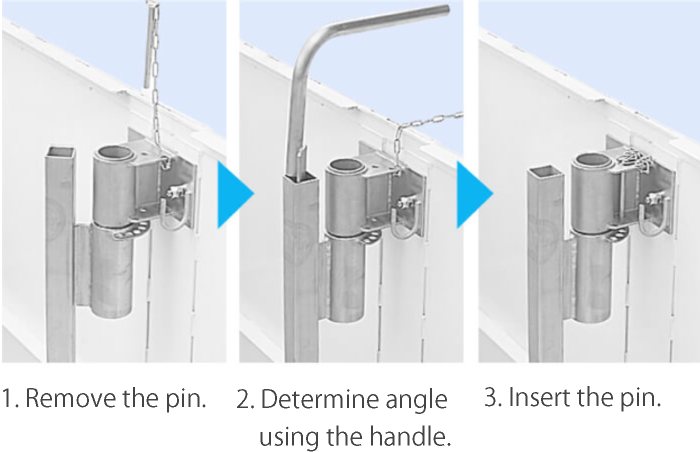

3. Left/Right Angle Adjustment

Mixing direction in horizontal can be adjusted within + / - 60° with 20° pitch.